Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

With the

transition towards energy supply which has to be based more and more on energy

efficiency and CO2 reduction the decentralized energy systems will

play an important role now and in the future. In general the combined heat and

power (CHP) technology is a well-known and established engineering solution for

energy efficient energy supply. But it is new that the market is getting ready

now also for small-sized CHP units for one- or two-family houses as it was

presented at this year´s ISH in Frankfurt/Germany for

example under the topic of Micro-CHP appliances. This article describes these

appliances only for the three different technologies “Stirling

Engine”, “Internal Combustion Engine” and “Fuel Cell” with the help of some

product examples.

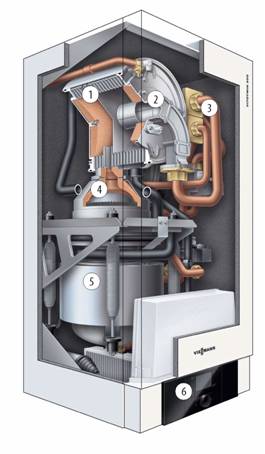

The ViessmannVitotwin 300-W (Figure 1) is an example for a Micro-CHP appliance with a Stirling

engine (Figure 2) which is hermetically sealed and

almost maintenance-free. It runs quietly and therefore it allows an installation

close to the living space.

The gas

fired stirling engine

generates 6 kW heat with an efficiency of 81% (gross cv)

and 1 kW power with an efficiency of 15% (gross cv)

simultaneously. The integrated gas fired peak load boiler of the Vitotwin 300-W can generate heat between 6 kW and 20 kW

in addition with 98% efficiency (gross cv).

Therefore this high-efficient Micro-CHP is suitable for old and new detached

houses and also for two-family houses. With an annual consumption of gas of 26 000 kWh

or more and power consumption above 3 000 kWh per year the Micro-CHP

works with exceptional economy.

The stirling engine operates in a

heat-led mode. The constantly generated power of 1 kW covers the base load

of the electricity demand on site and surplus power is exported to the public

grid, which is remunerated.

Due to the

daily fluctuation of the heat consumption on the one hand and the constantly

generated heat during the operation of the Micro-CHP on the other hand the combination with a heating water buffer

cylinder is essential (Figure 3).

1 - ViesmannInox-Radial heat exchanger

η= 96%

2 - MatriX cylinder burner, Modulation range 4.5–20 kW, Nox <40 mg/kWh, CO <50 mg/kWh

3 - Air distribution valve

4 - Stirling burner

5 - Stirling engine, Performance = 1 kWel,

Maintenance-free

6 - Control

Figure 1.

Wall mounted ViessmannVitotwin

300-W Micro-CHP appliance with a Stirling engine

(lower half) and with integral peak load boiler (upper half). Image source: www.Viessmann.com

A - Hot area, B - Displacer piston, C - Cold area, D - Working piston, E - Power generation, F - Cylinder retriever

Figure 2.

Hermetically sealed Stirling engine with the

heating-up heat exchanger and the displacer in the upper part, water-cooled

heat exchanger in the middle part and power piston, springs, coil and magnets (Linear Generator for electrical

output) in the lower part. The displacer moves helium from the heated area to

the cooled area. The alternately heated and cooled helium expands and contracts

what creates pressure waves and that then again let the working piston move.

The working piston is a part of the linear generator which produces electricity

while the working piston is moving. Image source: www.Viessmann.com

Figure 3.ViessmannVitotwin 300-W Micro-CHP appliance with a heating water buffer

cylinder. Image source: www.Viessmann.com

The VaillantecoPOWER 1.0 is an

example of a Micro-CHP appliance with an internal combustion engine (Figure 6).

Figure 4.

Gas-Internal Combustion Engine (single-cylinder four-stroke piston engine).

Electrical output 1 kW with efficiency of 26.3%, thermal output 2.5 kW

with efficiency of 65.7% and total efficiency of 92% (nettcv). Image source: www.Vaillant.com

Figure 5 demonstrates all the components

which belong to the VaillantecoPOWER

1.0 system. It operates in a heat-led mode and is suitable for single-family

and two-family houses with an annual heat demand of 15 000 to 25 000 kWh

per year. Together with the different available peak load boilers the Micro-CHP

system can generate a thermal output of 2.5 to 28.3 kW (60/40°C). With an annual

operation above 4 500 hours per year the Micro-CHP works with exceptional economy.

Figure 5.

Components of the Micro-CHP system of VaillantecoPower 1.0: wall-mounted gas-fired peak-load condensing

boiler (left), Micro-CHP unit and heat-transfer module with system controller

(center), multi-function cylinder with 300 liter or 500 liter capacity and

external heat exchanger for domestic hot water (right). Image source: www.Vaillant.com

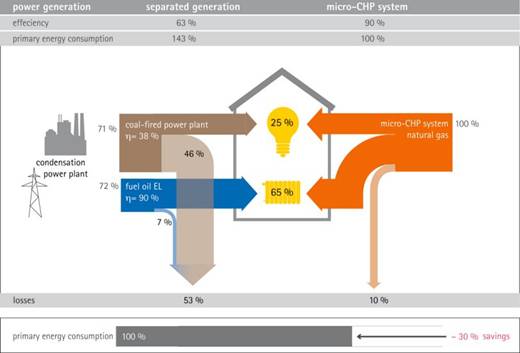

In Figure 6

two scenarios of heat and power supply of a building are compared. On the one

hand there is a power generation with a coal-fired power plant together with a

gas boiler on site and on the other hand there is a micro-CHP on site. In this

example it turns out that the micro-CHP appliance can save 30% of the primary

energy compared with the low-efficient power plant solution.

Figure 6.Comparison between a separated and a micro-combined heat and

power generation. Image source: www.ASUE.de

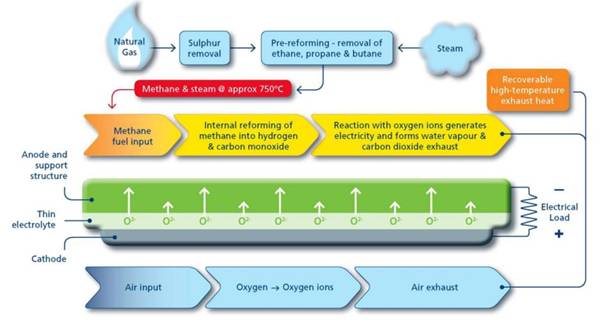

A product

example of a fuel cell-based micro-CHP unit called “BlueGen”

is shown in Figure 7. The natural gas-fired unit works

with a high temperature solid oxide fuel cell (Figures

8 and 10) and

can generate up to 2 kW electrical output with up to 60% efficiency (nettcv). Then with the utilization

of the simultaneously generated thermal output up to 1 kW W the total

efficiency of the “BlueGen” can increase above 80%.

For this case of operation the CO2-reduction could be 50% and more

compared with a separated heat and power generation of average existing energy

efficiency.

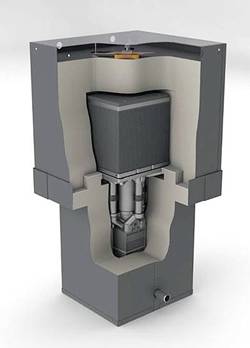

Ongoing

tests just try to find out how far the “BlueGen” can

cover the annual heat consumption and also the annual electrical consumption of

single-family or two-family houses in a power-led mode with a peak load boiler

and an optimized heating water buffer cylinder in addition (1).

Figure 7.

In front with about the size of a washing machine the fuel cell-based micro-CHP

unit “BlueGen” of Ceremic

Fuel Cells Ltd. together with a different heating water test buffer cylinder

(1). Laboratory of Heating Technology at Cologne University

of Applied Sciences/Germany (http://www.f09.fh-koeln.de/fakultaet/personen/profs/klaus.sommer/00835/).

Image source: www.Rheinenergie.com

Figure 8.

Functional principle of the high temperature Solid Oxide Fuel Cell (SOFC);

source: Ceramic Fuel Cells Limited. Image source: www.cfcl.com.au

Figure 9.Opened “BlueGen” with the high

temperature solid oxide fuel cell stack in the upper part.Laboratory of Heating Technology at Cologne University of Applied

Sciences/Germany (http://www.f09.fh-koeln.de/fakultaet/personen/profs/klaus.sommer/00835/).

Compared

with separately generated heat and power the gas-fired micro-CHP appliances

with stirling engine,

internal combustion engine or high temperature solid oxide fuel cell save

energy and reduce CO2-production for old and new one- or two-family

houses. The heat-led “Stirling engine” and “Internal

combustion engine” are designed for 1 kW electrical output with an

electrical efficiency of 15% and 26.3% and CHP-generated thermal output of 2.5 kW

or 6 kW. Together with a peak load boiler the thermal output of these

appliances varies up to around 28 kW dependent on the chosen performance

of the peak load boiler. The high temperature solid oxide fuel cell is designed

for power-led operation with a very high electrical efficiency up to 60% and an

electrical output up to 2 kW together with a thermal output up to 1 kW.

(1) Two-year

research project (2011-2013) “Analyzing of the real operating characteristics

of a high-efficient fuel Cell-based Micro-CHP in order to find out the best

possible application for residential buildings and to get real system

characteristics”; project leader Klaus Sommer. Funded

by KlimakreisKoeln (www.klimakreis-koeln.de), Rheinenergie

(www.rheinenergie.com) and Cologne University of Applied Sciences (www.fh-koeln.de).

Follow us on social media accounts to stay up to date with REHVA actualities

0