Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

Seppo EnbomSenior ScientistVTT Technical Research | Hannu SalmelaResearch ScientistVTT Technical Research | Matti LehtimäkiPrincipal ScientistVTT Technical Research |

|

|

|

Tapio KalliohakaResearch ScientistVTT Technical Research | Kimmo HeinonenResearch ScientistVTT Technical Research | Matti NiemeläinenSenior Research TechnicianVTT Technical Research |

Keywords:

air conditioning, indoor air quality, air filtration,

supply air diffusors, electret filters, particle concentration. |

A significant reduction of the particle concentration of the indoor air requires that 1) the particle concentration of the supply air can be essentially reduced and 2) considerably more clean air can be supplied into the indoor environment. Considering the techno-economic limitations (investment and operation costs), the prerequisite is that the improvement should be achieved without adding the ventilation rate and the size of the air conditioning system.

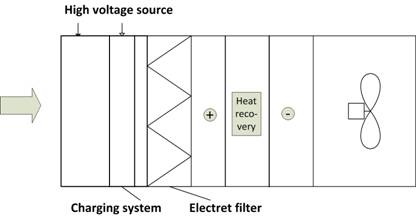

In an air handling unit (AHU), the increase in filtration efficiency of the supply air can be achieved by electrically charging the particles and utilizing electret filters for the particle filtration (Figure 1). This solution can be usually implemented without major changes in the air handling unit. The electric power consumption due to the charging of the particles is in the range of 1 W/m³/s which is practically insignificant. Because the pressure drop of the charger-filter combination is in the same range as with traditional filters, the energy consumption of fans is not increased.

Figure 1. An electric charging system and an electret filter installed in an air handling unit.

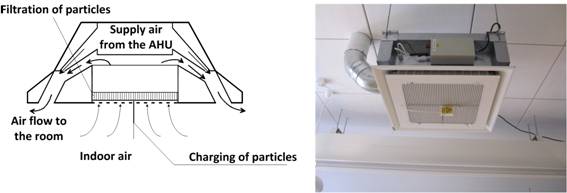

In an indoor environment, the influence of the filtered supply air can be significantly increased by removing particles also from the secondary air flow induced by the supply air entering room from the diffuser. (Figure 2) [1][2]. It must be emphasized that the flow resistance of the particle removal system must be very low. Although the use of mechanical filters with pressure drop below 5 Pa has been reported [3], efficient utilization of secondary air filtration requires much lower pressure drop. The prototype device developed at VTT is equipped with a special electrostatic air cleaning system which provides an effective particle removal at extremely low pressure drop level (<1 Pa).

Figure 2. Operating principle (left) and a prototype (right, modified Swegon Parasol) of the air diffuser equipped with particle filtration.

Some of persons who have been exposed to harmful pollutants (e.g. moulds) of the indoor air have become sensitive to such an extent that they are not able to stay even in renovated indoor air premises [4]. It is reasonable to assume that significant improvement of indoor air quality, achievable without costly modifications of the ventilation systems, could make it possible for these people to continue working, e.g. in office and school buildings.

The new particle filtration solutions enable to produce distinctly cleaner indoor environments only by applying the solutions into existing air conditioning systems. To achieve the best result, both the air handling units and the air diffusers should be equipped with the new solutions.

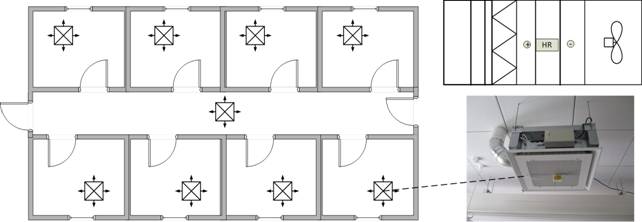

An example of clean indoor air premise where the concept has been applied is illustrated in Figure 3.

Figure 3. Application of the concept in an office unit: the air handling unit is equipped with the charger/electret filter combination and the air diffusers with the particle filtration.

The effect of the air purification concept to particle concentration of the indoor air has been measured in VTT´s office building in Tampere, Finland. The supply air filtration solution (Figure 1) was installed to an air handling unit that provided the supply air to a small office wing consisting of three rooms. Four air diffusers provided with the particle filtration (Figure 2) were installed to the wing.

Before the installations, the particle removal efficiency of the air diffuser was measured in a 233 m³laboratory test room. According to the experimental results, it was assessed that with the air diffuser (modified Swegon Parasol) it is possible to achieve ca. 65–67% reduction of the particle concentration in the selected office rooms. It is worth mentioning that the available pressure in the supply air duct was slightly too low for optimal operation of the air diffuser.

After the installations, the particle concentration was monitored from three locations:

· the supply air from the air handling unit into the air diffuser,

· the supply air into the room from the air diffuser, and

· the indoor air.

The particle concentrations were measured in three different conditions:

· neither of the filtration solutions were in use (reference situation with F7 class filtration in the air handling unit)

· the air diffuser solution was in use, and

· both the air handling unit solution and the air diffuser solution were in use.

The measurements were performed with a MetOne 3313 particle counter equipped with a multi-valve sampling system controlled by a computer.

The measurement results are presented in Figure 4. The particle concentrations have been normalised based on the particle concentration of the supply air from the air handling unit. When both solutions are off, the relative particle concentration in the room was 92% compared to the supply air from the AHU. The corresponding value was 36% when the air diffuser solution was in operation, and 12% when both the AHU and the air diffuser solutions were in operation.

Figure 4. Effect of the air purification solutions to particle concentration in an office room.

According to the results, the ability of air conditioning systems to control the particle concentration of the indoor air can be considerably improved without increasing the ventilation rate or without major increase in the energy consumption. A minor increase of energy consumption is possible if the pressure in the supply air duct must be raised in order to generate adequate secondary air flow through the air cleaning system.

In the laboratory studies, it was assessed that with the used air diffuser solution it was possible to achieve ca. 65–67% reduction of the particle concentration. In practice, the particle reduction in an office room was slightly lower, 63%. This is probably due to the air infiltration, i.e. uncontrolled air flows through the air leaks in the building. It has been estimated that the achieved reduction percentage can be regarded as typical value for the new air cleaning system. However, it must be emphasized that the prototype system was constructed from an existing supply air device. It is possible that the operation of the air cleaning technique can be improved by careful optimization of the structure of supply air diffuser.

The subsystems of the modular concept can be used together or separately depending on the application and the target level of the particle concentration. To achieve the best result (90% reduction), both the air handling units and the air diffusers should be equipped with the novel filtration solutions. The air purification solutions presented in this paper can be used to create building sections with enhanced indoor air quality e.g. in office or school buildings, hotels, hospitals or in premises used for demanding industrial production.

The development work of the air diffuser solution started with a small project in 2008 funded by TEKES, the Finnish Funding Agency for Technology and Innovation. The development work continued in 2012-2013 funded by VTT. Since 2013 the development work has continued in a research project funded by the Finnish Work Environment Fund, VTT and other co-operating organisations.

The electric filtration technique of the air handling unit has been studied in 2012-2013 funded by VTT.

1. Enbom, S. and Lehtimäki, M. 2009. Sisäilman puhdistaminen

ilmanjakolaitteessa – ratkaisu sisäilmaongelmiin. Sisäilmaseminaari 2009. 6 s.

In Finnish.

2. Taipale A., Enbom S., Lehtimäki M., and Säämänen A. 2009. ISAC: a novel air cleaning technique for controlling indoor air quality – Utilization of the induced air flow in the supply air diffuser. In: proceedings of Healhty Buildings: Paper 461.

3. Ardkapan, S. R., Afshari, A., Bergsøe, N. C., Gunner, A. and Afshari, J. 2012. Combining active chilled beams and air cleaning technologies to improve indoor climate in offices: Testing a low pressure mechanical filter in a laboratory environment, Healthy Buildings 2012: 10th International Conference. Brisbane, Australia, Queensland University of Technology.

4. Reijula K., Ahonen, G., Alenius H., Holopainen R.,

Lappalainen S., Palomäki E. and Reiman M., 2012. Rakennusten kosteus- ja

homeongelmat. Eduskunnan tarkastusvaliokunnan julkaisu 1/2012. 205 s. In

Finnish.

Follow us on social media accounts to stay up to date with REHVA actualities

0