Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

|

Hilde BreeschKU Leuven Technology Campus GhentResearch group Sustainable BuildingsBelgium | Barbara WaumanKU Leuven Technology Campus GhentResearch group Sustainable BuildingsBelgium | Ralf KleinKU Leuven Technology Campus GhentResearch group Sustainable BuildingsBelgium | Alexis VerseleKU Leuven Technology Campus GhentResearch group Sustainable BuildingsBelgium |

A new nZEB school building is realised at the Technology campus Ghent of KU Leuven (Belgium) on top of an existing university building (see Figure 1). The building contains 4 zones (see Figure 2): 2 large lecture rooms (zone 1 and 2), a staircase (zone 3) and a technical room (zone 4). The lecture rooms have a floor area of 140 m², a volume of 380 m³ and a maximum capacity of 98 students each. Windows are provided on both sides of lecture rooms, the window-to-wall ratio is 27% (SW) and 26% (NE), the window-to-floor ratio is 14%.

Figure 1. nZEB school building at Technology campus Ghent of KU Leuven (Belgium).

|

|

Figure

2. Floor plan of lecture room (left) and section of test school building

(right). | |

The aim of this project is to realise a school building that is used as normal lecture rooms but at the same time is a test facility for research on building energy-efficiency strategies in a “real use” environment. Therefore, the 2 lecture rooms are thermally insulated from the outside, the neighbouring zones and each other. The lecture rooms are also designed as identical zones with a different thermal mass. The lower class room has a brick external wall with exterior insulation. The upper class room has a lightweight timber frame external wall with the same U-value. Both lecture rooms have a concrete slab floor.

Moreover, the building is designed according to the passive house standard. This requires a highly insulated and airtight building (n50 < 0.6 h-1) with a net heating and net cooling demand ≤ 15 kWh/m².a [1]. This is a challenge for a school building with (1) a dense occupancy (1.4 m²/student) and thus high internal heat gains, (2) high ventilation rates and thus ventilation losses (5.8 h-1 in the lecture rooms) and (3) intermittent use. In addition, an increased need for cooling and high temperatures in summer and shoulder season are expected in this highly insulated and airtight school building.

This paper discusses how to fulfil the requirements of a passive school building (focusing on heating) while guaranteeing a good thermal summer comfort. Design choices are considered and the final solution, i.e. the building with its HVAC systems and control, are presented.

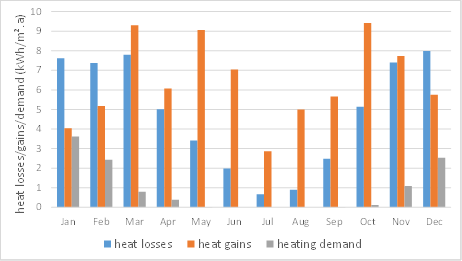

First, the net energy demand for heating of this school building design is evaluated. This demand is calculated by the quasi-steady state calculation method PHPP 2007 [2] adapted for school buildings, based on EN 13790.

The following assumptions are made. The occupant density during courses is 1.4 m²/pers. This value is comparable to the occupancy that DIN V 18599 assumes for auditoria rather than for classrooms. This density is increased to 200% during exams. An absenteeism of 10% is taken into account. The operational schedule: the academic year counts 124 days with courses and 63 days with exams (in January, June and August-September). Holiday periods are in April (2 weeks), July and the first half of August (6 weeks) and December-January (2 weeks). The lecture rooms are in use from Monday to Friday between 8h10 and 16h30. The internal heat gains amounts to 80 W/pers. due to occupants, 1 W/m² due to equipment and 6 W/m² due to lighting according to [3]. The ventilation rate is 29 m³/h.pers. [3] corresponding to IDA3 in EN 13799. The ventilation system consists of a balanced mechanical ventilation provided with an air-to-air heat exchanger with an efficiency of 75%. Building envelope has a U-value of 0.15 W/m²K and includes triple glazing windows (U = 0.85 W/m²K and g = 0.52). The average indoor temperature is 19.4°C [3]. Monthly average measured weather data (1971–2000) for the meteorological station of Uccle (Belgium) [3] is used.

This calculation results in a yearly net

heating demand of 11 kWh/m².a. This means that this building design

fulfils the requirements of Passive House standard concerning the net energy

demand for heating in school buildings

Figure 3. Monthly heat losses, heat gains and net heating demand (in kWh/m².a).

Thermal summer comfort and net cooling demand are evaluated using dynamic simulations in TRNSYS [4].

Following assumptions are made, in addition to the preceding assumptions for the calculation of the net heating demand. A hot weather data set for Uccle (Belgium) [5] with warm temperatures with an occurrence once every 10 year is used. The simulation time step is 10 min. Moveable external sunblinds are provided on both façades. The threshold of total solar radiation when blinds are closed or opened is 250 W/m2. In case the blinds are closed, 75% on the shaded surface is blocked. The air-to-air heat exchanger is bypassed when the indoor operative temperature exceeds 22°C and the outdoor air is cooler than the indoor air. The minimum supply air temperature is 14°C.

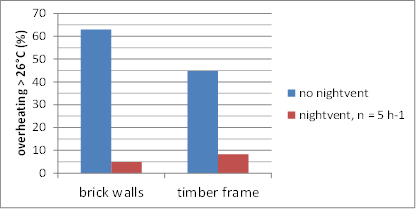

The impact of night ventilation on thermal summer comfort is studied. Night ventilation is activated at night (between 0h and 6h) when the indoor air temperature exceeds the outdoor air temperature with at least 2°C and the surface temperature of a massive wall exceeds 21°C.

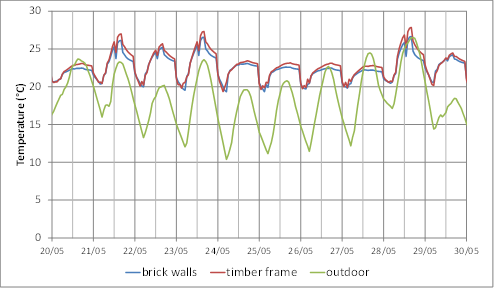

Figure 4 evaluates thermal summer comfort in both lecture rooms and shows the effect of night ventilation. The amount of hours exceeding 26°C (in % of the time in use) is shown. As expected, without night ventilation, none of the rooms meet the requirement of overheating hours less than 5% of the time in use according to EN 15251. A significant impact of night ventilation is depicted in Figure 4. However, the requirement for good thermal summer comfort is not fulfilled in the upper lecture room with timber frame external wall. In addition, Figure 5 shows the indoor temperatures in both rooms during a week at the end of May. Thermal comfort is reasonable but not excellent. This means that additional (ventilative) cooling is needed to reach a good level of thermal comfort in summer, spring and autumn in both lecture rooms.

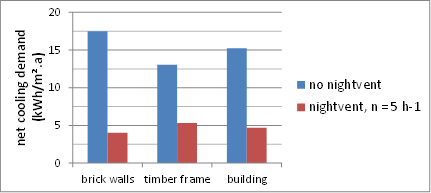

On the contrary, the net cooling demand fulfils the PassiveHouse requirement of 15 kWh/m².a, even without night ventilation when looking at the whole building (see Figure 6). When night ventilation is applied, both lecture rooms have a net cooling demand of less than 6 kWh/m².a. This means that assessment of the net cooling demand of a whole building does not guarantee a good thermal comfort in the separate zones.

Figure 4. Evaluation of thermal summer comfort.

Figure 5. Indoor temperature in both lecture rooms (with night ventilation).

Figure 6. Evaluation of net cooling demand.

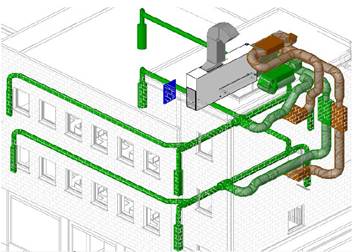

The building is equipped with an all air system with balanced mechanical ventilation with a the total supply airflow of 4 400 m³/h (i.e. 22.4 m³/h.pers). Figure 7 depicts this HVAC system with the AHU in the technical room and the distribution in the staircase and in the lecture rooms. Demand controlled ventilation with 4 VAV boxes control the airflow based on CO2-concentrations in the rooms. For heating purposes, the air is preheated by air-to-air heat recovery, i.e. two cross flow plate heat exchangers connected in series, with an efficiency of 78%. Additionally, heating coils of 7.9 kW each are integrated in the supply ducts in each lecture room.

The building is cooled by three techniques of ventilative cooling: (1) a modular bypass in the AHU (2) hybrid night ventilation (natural supply by opening the windows and mechanical exhaust) and (3) indirect evaporative cooling (IEC) with a maximum capacity of 13.1 kW. In addition, external sunblinds (screens) are provided on the southwestern façade and automatically controlled.

Artificial lighting has a low normalized power density (1.49 W/m².100 lx ) and is equipped with daylight control system, i.e. a closed loop system with centrally positioned daylight sensor.

Figure 7. Ventilation system (green is supply, brown is extraction).

A set of sensors has been installed to monitor indoor and outdoor conditions and is described in [6]. The building has its own weather station which monitors the main outdoor parameters: solar radiation, the outdoor temperature and humidity and the wind speed and direction. For the indoor conditions, the indoor temperature, the CO2 concentration and the indoor humidity are continuously monitored. Occupancy level is measured by motion detection sensors and high definition camera with face recognition.

The first monitoring results of this building are available and discuss the operation and ventilation efficiency of demand controlled ventilation [7].

[1] Flemish Governement, "Decree of December 7, 2007 - Decree concerning energy performances in school buildings," 2007.

[2] PassivHaus Institut, Passivhaus Projektierungs Paket (PHPP) version 2007, http://www.passiv.de/index.html, 2007.

[3] B. Wauman, R. Klein, S. Van Loon, R. Baetens, H. Breesch and D. Saelens, "Determination of boundary conditions for passive schools: impact on net energy demand for heating and cooling," in CESBP, Krakau, Polen, 2010.

[4] S. Klein, W. Beckham and D. Mitchell, "TRNSYS 17: A Transient System Simulation Program," Solar Energy Laboratory, University of Wisconsin, Madison, USA, 2010.

[5] Meteotest, Meteonorm version 5.1- Edition 2005.

[6] R. Andriamamonjy and R. Klein, "A modular, open system for testing ventilation and cooling strategies in extremely low energy lecture rooms," in 36thAIVC Conference, Madrid, 2015.

[7] B. Merema, M. Sourbron, J. Verplaetsen, P. Van den Bossche and H. Breesch, "Demand controlled ventilation in practice: Case study," in 36th AIVC Conference, Madrid, 2015.

Follow us on social media accounts to stay up to date with REHVA actualities

0