Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

As with all dedicated systems, good technical knowledge and installation skills are needed in order to avoid problems caused by design and installation mistakes, which could easily destroy the reputation of any good system. REHVA set up Residential Ventilation Task Force in 2016 to develop an European guidebook including all information and calculation bases needed to design, size, install, commission and maintain Heat Recovery (HR) ventilation properly. If followed by practitioners, a challenge of silent, clean, draft-free and energy efficient ventilation can be solved European wide. The guidebook is expected to be published in March 2018 as REHVA-EUROVENT joint guidebook.

The guidebook includes major topics as selection of ventilation units, pressure drop and noise calculations, ventilation system layouts and installation in new and renovated buildings. It is mainly focused on centralized (one ventilation unit per staircase or building) and decentralized (one ventilation unit in every apartment) ventilation systems of Facade ventilation units were not seen suitable for nearly zero energy buildings because of many problems in operation and were excluded from the guidebook. When it is easy to install HR ventilation to new buildings, there are much more challenges and special solutions in renovation. To tackle this highly important market, best practice solutions were collected from North and Central Europe countries.

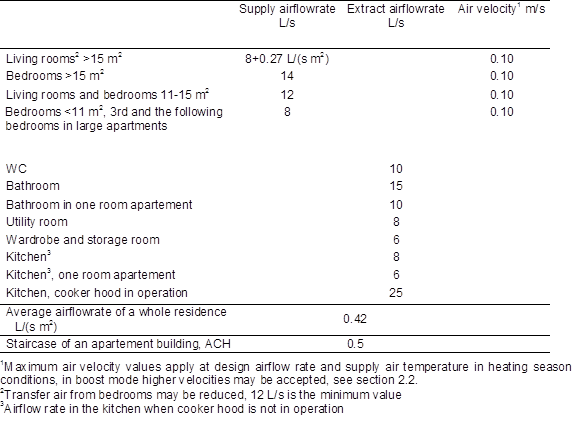

Airtight and highly energy efficient buildings create some new challenges for ventilation. There is no consensus in national regulation and guidelines about ventilation need, but latest standards FprEN 16798-1:2016 (replacing EN 15251:2007) and ISO 17772-1 include new section for airflow rate selection in residences. This is further developed by REHVA to be suitable for practical design, mostly with room-based supply and extract airflow rates, (see Table 1).

Table 1.

Highlight from the new guidebook – an easy and straightforward room by room

airflow rate selection procedure in residences. The values are to be multiplied

by 3.6 to recalculate to m³/h units.

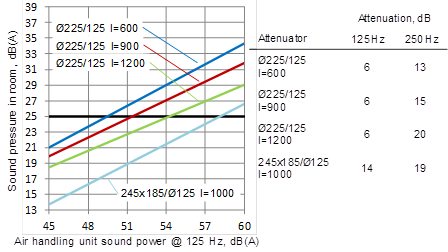

Noise calculation is perhaps the most “overkill” ventilation system calculation for most of practitioners. This has led to the situation where ventilation units are just installed without sound power and pressure calculation and this has resulted in many noise problems, because of undersized units or poor sound attenuation. For this reason, in addition to presenting noise calculations, the guidebook introduces noise prediction method which does not need any calculation. An example is shown in Figure 1.

Figure 1.

Selection of sound attenuator based on the sound power of the ventilation unit

at frequency 125 Hz at design airflow rate. For example, if the sound

power of the unit to supply duct is 54 dB, “green” silencer is required

(1200 mm) to achieve 25 dB(A) sound pressure in bedrooms.

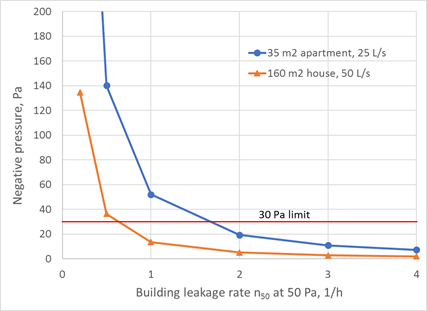

Nearly Zero Energy Buildings are expected to be very airtight, with building leakage rate below 1 air change at 50 Pa. This provides new challenges for ventilation system balancing, especially in the case of cooker hood, fireplace or central vacuum cleaner operation. In airtight dwelling, a conventional cooker hood with 25 or 50 L/s exhaust, as considered in Figure 2 example, can easily result in 100 Pa and more negative pressure. This occurrence becomes a safety issue, because doors cannot be opened by children if pressure difference is more than 30 Pa. Therefore, in all new buildings, cooker hoods are to compensated with supply air.

Figure 2.

Conventional cooker hood in airtight nearly zero energy building leads easily

to more than 100 Pa negative pressure.

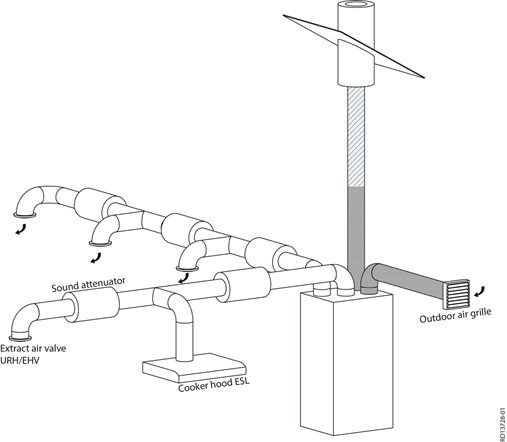

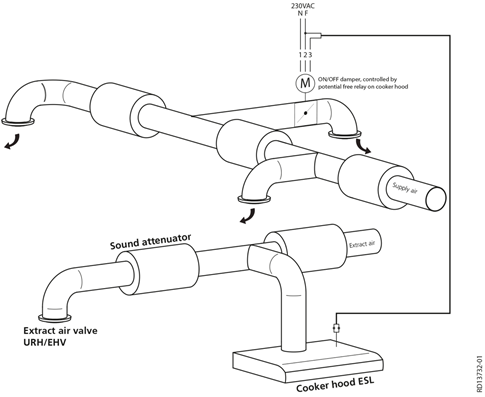

To achieve balanced operation, cooker hoods are recommended to be connected to ventilation units. In the case of units with plate heat exchanger, cooker hoods can be directly connected so that the extract air goes through the heat exchanger (see Figure 3). Units with rotary heat exchanger have special inlet for cooker hoods bypassing heat recovery.

Figure 3.

Cooker hood connected to ventilation unit with plate heat exchanger.

In the case of centralized ventilation system, cooker hoods are similarly connected to extract air ductwork and central ventilation units must have plate heat exchangers. Opening the cooker hood will boost the ventilation. To compensate this, a voltage signal is used to open one additional supply air diffuser (see Figure 4). In such system, pressure sensor keeping constant pressure in risers will increase the fan speed, which means that the system still can be kept relatively simple ensuring reliable operation and low maintenance need.

Figure 4.

Cooker hood compensation in centralized ventilation system. During the

operation, an additional supply air diffuser is opened.

Follow us on social media accounts to stay up to date with REHVA actualities

0