Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

Aleksandra ZarzyckaRoyal HaskoningDHVEindhoven University of TechnologyThe Netherlandsal.zarzycka@gmail.com | Wim MaassenRoyal HaskoningDHVEindhoven University of TechnologyThe Netherlandswim.maassen@rhdhv.com | Wim ZeilerEindhoven University of TechnologyThe NetherlandsW.Zeiler@tue.nl |

The health care sector is highly energy

intensive. Worldwide, circa 6% of the total energy consumption in the buildings

sector is represented by energy usage in medical centres. For this reason,

hospitals strive to reduce their consumptions and CO2-emissions. In

order to meet the requirements, set by the European Union Energy Performance of

Buildings Directive (EPBD), all buildings (residential and utility) need to

comply to Nearly Zero Energy Building requirements according the EPBD [1].

Previous study [2] has looked into energy consumptions of various spaces within

a hospital and concluded that for Dutch hospitals the energy reduction

potential seems to be the highest in isolation rooms and operating theatres

(OTs). For the OTs the highest energy consumption is attributed to the amount

of supplied air, energy used for fans and the time that surgery rooms are in

operation.

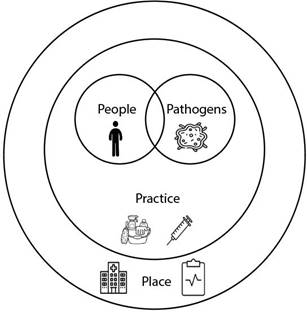

In this study the possibility to reduce energy

consumption in the OTs is investigated, using an approach that puts the human

and his safety in the centre of attention. Most important factors in infection

prevention are therefore categorized into four groups, the so called ‘four Ps’:

pathogens, people, practice and place (Figure 1). In the

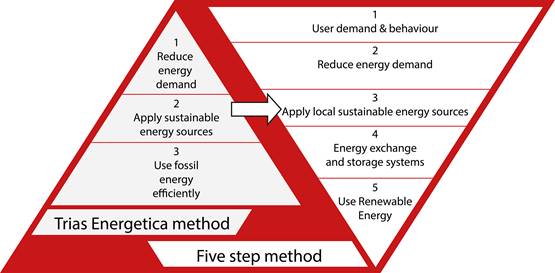

Netherlands, a commonly used approach for an energy-efficient building design is

the three-step strategy called ‘Trias Energetica’ [3]. Due to increasing

concern and evolution of techniques, the ‘Trias Energetica’ has been upgraded

to a ‘Five-Step Method’ [RHDHV], as can be seen in Figure 2.

The additional steps to the original approach are: user demand and behaviour

(point 1) and energy exchange and storage systems (point 4). The former step

implements the ‘user-oriented’ concept through smart building designs and

controls. The focus on the user and his primary process results in possibilities

for improvements of indoor climate as well as productivity. Furthermore, it can

substantially decrease energy use. This idea is further developed in this

research. By investigating the parameters needed to create a safe environment,

starting from the most basic layer such as bacteria transmission, the project

aims to draw conclusions on the actual requirements for a healthy indoor

environment in the OT, questioning the current standards. Is such a high air

exchange rate necessary? Are current systems the most efficient infection

prevention methods? How can the OT be optimized for a high surgical

performance? These questions can only be answered by understanding the actual

needs of this specific environment, therefore the focus on user demand and behaviour

is crucial.

Figure 1. Four “Ps” of infection prevention.

Figure 2. Building design approaches: ‘Trias

Energetica’ versus the upgraded ‘Five Step Method’.

The total

annual number of patients that suffer from surgical site infections (SSIs)

amounts to 1.12% for European hospitals [4]. Inside the operating theatre, bacteria can reach the wound either by

dislocation within patient’s own microbiota, through air or from poorly

disinfected tools. The shedding of bacteria from staff’s skin is

considered one of the biggest potential sources of wound contamination [5].

Each person sheds around 10,000 skin particles per minute into the air while

walking. Approximately 10% of these are estimated to carry bacteria [6]. Skin

fragments carrying bacteria have an average size of 12 μm (range

between 4-60 μm). Surgical-site contamination by airborne particles

is ascribable in 30% of cases to direct settling of the particles on the wound

and in 70% of cases to settling on the instruments and surgeon’s hands followed

by transfer to the wound [7].

There are

several environmental factors that may impact the infection acquisition, from

which four are of relevance in the operating theatre: relative humidity (RH),

temperature, air speeds and movement intensity of the particles. There is

research showing that maintaining the humidity levels in the range between 40

and 60% can be related to decreased infection rates in hospitals [8],[9]. This

is due to lower possibility of droplets to remain suspended in the air for

prolonged periods of time, prevention of mucous membrane from drying out,

shorter life span of bacteria and viruses in such conditions and lack of

accumulation of static electricity with higher humidities [10],[11].

On the

other hand, professionals argue that relative humidity is not of such

importance and there is no need to pay close attention to its levels.

While the

primary focus of indoor environment in operating theatres is on infection

prevention, thermal comfort of the workers tends to be generally overlooked.

Study performed by Ilse Jacobs focused on the thermal sensation of surgical

staff members in OTs equipped with different ventilation systems [12]. The

conclusion of the research was that surgeons tend to feel from slightly warm to

hot, anaesthetists and nurses from slightly cool to cold, and the patient from

slightly cool to very cold. Only the surgery-assistant experiences a

comfortable environment with the current environmental and clothing parameters

according to Van Gaever et al. [13].

When it

comes to the patient, a study by Khodakarami et al. stated that the temperature

must not drop below 21°C [11]. However, a temperature above 23°C already

becomes intolerable for the surgical staff. During an operation, body

temperature is lowered due to open body wounds, infusion of cold fluids,

inhalation of cold gases and lowering muscle activity or because of the

pharmaceutical agents given to the patient. Even mild hypothermia can lead to

numerous complications, which might lower the resistance to surgical wound

infection [14]. A 36% decrease in infection rates was observed by Melling in

patients who received some form of warming during the surgery [15].

In an

environment where anaesthetic measures are suppressing immune system of a

patient and a direct contact between him and OT staff is frequent, failure to

maintain highest standards of (hand) hygiene can result in increased infection

risk.

Table 1 summarizes factors associated with

surgical-site infections. The icon representing a group of people means that a

factor is related to discipline. Icon with a piece of paper shows the

connection to rules and regulations. Icon with a light bulb means the relation

with the skills of the operating team.

Table 1. Factors associated with surgical-site

infection.

Operation

characteristic | |

| Inadequate surgical team

preoperative hand and forearm antisepsis |

| Inappropriate or untimely antimicrobial prophylaxis |

| Inadequate sterilization of

instruments |

| Contaminated OT environment |

| Inappropriate surgical

attire and drapes |

| Inadequate preoperative skin preparation |

| Inappropriate preoperative

shaving |

| Poor surgical technique: excessive blood loss, hypothermia, tissue

trauma, entry into a hollow viscus, devitalized tissues etc. |

| Excessive duration of

operation |

Table 2 shows an overview of some of the

factors that influence the occurrence of surgical site infections. It has to be

noted that these values vary between studies and very often it is hard to

estimate their role in reduction of SSI rates due to complexity of the surgical

environment and too many factors that are mutually dependent. For some

positions, for example surgical clothing, such an estimation was not possible,

therefore these were not included in the table.

Table 2. Influence of various factors on the decrease

in surgical site infection rates [16],[15],[17],[18].

Influencing factor | Decrease in SSI rates |

Hand

hygiene | 13-54% |

Proper

antibiotic use | 26-92% |

Occurrence

of hypothermia | 36% |

Preoperative

showering with chlorhexidine | 24.4% |

Type of intervention | up to 83.7% |

Health

state of the patient | up to 86.4% |

Operating

theatres can be classified depending on their performance as suitable for

high-risk operations or not. Ventilation system which is installed in a given

OT is responsible for providing clean air and maintaining the quality of the

environment according to the class of the room.

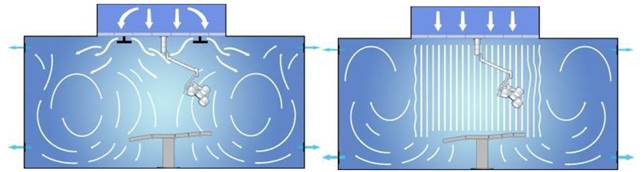

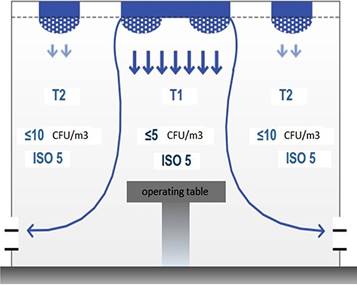

Figure 3. Flow patterns for the TMA (left)

and UDF (right) ventilation systems [12].

In general,

there are two main ventilation principles that are applied in OTs: mixing

ventilation (turbulent mixed airflow TMA) and displacement ventilation

(unidirectional flow UDF), as presented on Figure 3.

Turbulent mixed airflow supplies turbulent streams of HEPA filtered air through

diffusers on the ceiling, therefore creating a mixed ventilation in the whole

space of an operating theatre. The system is based on dilution principle, which

results in exponential decay of high concentrations of airborne microbes over

time [19]. Second type is a system supplying conditioned air in a parallel

stream to the surgical field. The streams of air move in parallel layers and,

with equal speed of around 0.4 m/s, reach the operating table. This

creates a sort-of protective curtain of airflow surrounding the surgical site.

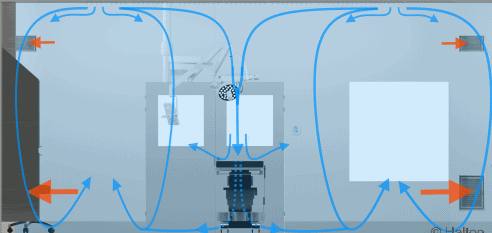

Apart from traditional systems, recent years have seen the emergence of new

systems, based on mentioned principles. Halton Vita OT Space is a system that

has been developed on mixing principle in the year 2015 and is presented on

Figure 4 below.

Figure 4. Halton - mixing ventilation

principle [20].

The

controlled dilution effect is created by circumferential air supply directed

both inward towards the operating area and outward towards the room periphery.

The emissions generated in the room periphery are diluted by additional air

supplied to periphery zone. Based on room dimensions, operational needs and

thermal comfort, airflow pattern can be adjusted. An example of a recently

developed system working on the principle of UDF is Optimus Integrated Surgical

Environment shown on Figure 5. In this approach the

entire operating complex is integrated into one solution, including lighting,

web cams, sensors, microphones and surgical cameras. The room air volume will

be replaced 30 times per hour at very low velocities [21].

Figure 5. Optimus Integrated Surgical

Environment – UDF ventilation principle [21].

A system

called Opragon (Figure 6) is based on a modification of

UDF - Temperature controlled Laminar Airflow (TAF). In this solution slightly

chilled, HEPA-filtered air is introduced to the room and distributed by low

impulse, half-spherically shaped air showers. They are mounted in a circle,

creating an ultra-clean zone. Outside of the zone, eight additional diffusers

are mounted on the ceiling, preventing stagnation zones in the periphery of the

room. Higher density of chilled air causes it to fall to the floor at a speed

controlled by the difference in temperature between the added air and the air

at the level of the operating table. The temperature difference of −1.5

to −3°C between the added ultra-clean air and the surrounding air in the

room at the operating table level needs to be maintained in order to guarantee

a speed of around 0.25 m/s at the operating table level [22].

Figure 6. Opragon ventilation system based on

TAF principle.

The

temperature gradient drives the central vertical flow of cooled air. The air

showers located in the outside zone provide control of the room temperature,

therefore there is no need for additional heating system, like in a laminar

downflow. A comparison between three mentioned systems is presented in Table 3.

Having conducted the literature research by starting from the human perspective

it is possible to distinguish new strategies for energy reduction and process

improvement. Traditionally the design of the operating theatres is based on

many steady-state parameters, while in practice these values vary greatly.

Aspects such as hand hygiene, skin shedding of the staff, parameters of the

clothing (in case multi-use attire is used), movement of the staff etc. cannot

be approximated with one number since they differ everyday depending on the

team. Moreover, environmental factors such as relative humidity and indoor

temperature can play a role in the spread of pathogens. When it comes to the

systems themselves, their design parameters such as the location of inlets/outlets

or location of heat sources in the room can greatly alter the way bacteria is

transported within the OT.

Table 3. Comparison of three ventilation systems [19].

Description | Turbulent mixing | Unidirectional flow | Temperature controlled

airflow |

ISO class in the centre

of the OR (steady-state) | 7 | 5 | 5 |

ISO class in the periphery of the OR

(steady-state) | 7 | 7 | 5 |

Protected area | No | Yes | Yes |

Recovery time <3 min | No | Yes | Yes |

Type of flow | Turbulent | UDF | UDF |

Acceptance for class Ia surgeries | No | Yes | Yes |

Average airflow (m³/h) | 3 200 m³/h | 12 000 m³/h | 5 600 m³/h |

Recirculation of air | 0% | 70% | 45% |

Noise level in

empty room | 45 dBA | 58 dBA | 48 dBA |

Ventilation power | 2.8 kW | 8.0 kW | 5.7 kW |

CFU/m³median(range) | 10 (0-162) | 0 (0-16) | 1 (0-29) |

It is

therefore crucial for the engineers and designers of the OTs to be able to

understand the way that bacteria travels in space and reaches the wound area of

the patient. With better understanding of these mechanisms, ventilation systems

could be adjusted to provide more precise and more energy-efficient solutions.

However, before the research on the bacteria transmission is completed, there

are several energy saving measures that can already be implemented in the

hospitals:

·

Airflow

control based on particle concentrations,

·

Variable

temperature with the outdoor weather,

·

Turning

down the system for the night,

·

Better

planning of the use of OTs based on operation type,

·

Removing

humidification,

·

Increased

air recirculation.

One of the

energies saving measures is airflow control based on particle concentrations.

This energy saving measure at the same time provides increased infection

prevention. By putting a real-time particle counter in the vicinity of the

wound, it is possible to get an immediate feedback on the number of particles

in that area. Although there is no direct correlation between the number of

particles and the amount of colony forming units, bacteria always need a

particle on which it can settle. Therefore, we can assume that if there is no

or very little particles in the air, the chance of finding bacteria is also

very low. Having a real-time feedback enables the system to reduce the amount

of air if there are no particles in the air and increase it in case there is a

significant of particles, thus improving infection prevention. This approach is

in line with the statement that OTs design cannot be based on steady-state

parameters. By the real-time measurement, the ventilation system can be

adjusted to the current situation and its needs. Another measure is related to

changing the absolute temperature inside the OT based on the outdoor

conditions. Even though the temperature difference between the inlet and outlet

air inside the room needs to be kept the same, the absolute values can vary

with seasons, allowing for energy savings. Third measure is related to turning

down the ventilation system for the night and it has been studied by

Dettenkofer et al. [23]. The authors have concluded that shutting down OT

ventilation during off-duty periods does not appear to result in an

unacceptably high particle count or microbial contamination and if the system

is restarted 30min before the scheduled operation, high levels of air quality

will be maintained. Fourth possibility is related to improved planning within

the hospital management. Not all operations need to be conducted in the highest

performance OTs, for which the energy consumption is very high in order to

provide the highest levels of air cleanliness. If a classification of operation

types is created, they could be distributed between two performance classes of

the OTs, leading to energy savings. Last two measures are already being widely

implemented in the USA with positive results regarding energy savings.

The article

shows added value the approach was the focus on energy conservation begins

primarily with the human needs and process conditions needed to supply a

productive, healthy and comfortable indoor environment. Starting from the

essential human and process needs it leads to an analysis resulting in relevant

energy conservation possibilities.

[1] EU, “Directive 2010/31/EU of the European

Parliament and of the Council of 19 May 2010 on the energy performance of

buildings (recast),” and Directive (Eu) 2018/844 Of the European Parliament and

of the Council of 30 May 2018 amending Directive 2010/31/EU on the energy

performance of buildings and Directive 2012/27/EU on energy efficiency.

[2] I. Schoenmakers, “Increasing HVAC energy

performance in University Medical Centres by optimizing energy efficiency

indicators,” p. 78, 2014.

[3] A. G. Entrop and H. J. H. Brouwers,

“Assessing the sustainability of buildings using a framework of triad

approaches,” J. Build. Apprais., 2010.

[4] “European Centre for Disease Prevention and

Control.,” Point Preval. Surv. Healthc. Assoc. Infect.

Antimicrob. use Eur. acute care Hosp., vol. 2013 SRC, 2013.

[5] M. A. Ritter, “Operating room environment,”

in Clinical Orthopaedics and Related Research,

1999.

[6] W. C. Noble, “Dispersal of skin

microorganisms,” British Journal of Dermatology.

1975.

[7] D. Chauveaux, “Preventing surgical-site

infections: Measures other than antibiotics,” Orthopaedics

and Traumatology: Surgery and Research. 2015.

[8] H. O. W. Radiology, H. T. O. Find, and F. L.

Diseases, “Breathe Easy,” 2016.

[9] G. J. Harper, “Airborne micro-organisms:

survival tests with four viruses,” Epidemiol. Infect.,

vol. 59, no. 4, pp. 479–486, 1961.

[10] A. V. Arundel, E. M. Sterling, J. H. Biggin,

and T. D. Sterling, “Indirect health effects of relative humidity in indoor

environments,” Env. Heal. Perspect, 1986.

[11] J. Khodakarami and N. Nasrollahi, “Thermal

comfort in hospitals - A literature review,” Renewable

and Sustainable Energy Reviews. 2012.

[12] I. Jacobs, “Thermal comfort of surgical staff

in operating rooms with different types of ventilation systems,” no. July,

2018.

[13] R. Van Gaever, V. A. Jacobs, M. Diltoer, L.

Peeters, and S. Vanlanduit, “Thermal comfort of the surgical staff in the

operating room,” Build. Environ., vol. 81, pp.

37–41, 2014.

[14] D. I. Sessler, “Mild perioperative

hypothermia.,” N Engl J Med, vol. 336, no. 24,

pp. 1730–1737, 1997.

[15] A. C. Melling, B. Ali, E. M. Scott, and D. J.

Leaper, “Effects of preoperative warming on the incidence of wound infection

after clean surgery: A randomised controlled trial,” Lancet,

2001.

[16] J. L. Alfonso-Sanchez, I. M. Martinez, J. M.

Martín-Moreno, R. S. González, and F. Botía, “Analyzing the risk factors

influencing surgical site infections: the site of environmental factors.,” Can. J. Surg., 2017.

[17] P. J. E. Cruse and R. Foord, “A Five-Year

Prospective Study of 23,649 Surgical Wounds,” Arch.

Surg., 1973.

[18] B. Friberg, S. Friberg, and L. G. Burman,

“Inconsistent correlation between aerobic bacterial surface and air counts in

operating rooms with ultra clean laminar air flows: Proposal of a new

bacteriological standard for surface contamination,” J.

Hosp. Infect., vol. 42, no. 4, pp. 287–293, 1999.

[19] M. Alsved et al.,

“Temperature-controlled airflow ventilation in operating rooms compared with

laminar airflow and turbulent mixed airflow,” J. Hosp.

Infect., vol. 98, 2017.

[20] “Halton.” [Online]. Available: https://www.halton.com/nl_NL/health/home.

[21] “Optimus Integrated Surgical Environment.

Integrated Air Plenum.” [Online]. Available: www.optimusise.com/components/integrated-air-plenum/.

[22] Airsonnet, “Opragon brochure,” 2009.

[23] M. Dettenkofer et al.,

“Shutting down operating theater ventilation when the theater is not in use:

infection control and environmental aspects,” Infect

Control Hosp Epidemiol, 2003.

Follow us on social media accounts to stay up to date with REHVA actualities

0