Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

The

Eurovent Certified Performance (ECP) certification is a voluntary, third party

certification managed and accredited according to the ISO/IEC 17065:2012 –

“Conformity assessment -- Requirements for bodies certifying products,

processes and services" requirements (COFRAC accreditation n°5-0517,

international recognition EA/IAF). Accreditation is a proof for independence

and competence. It also ensures that all manufacturers are allowed to have

their product certified without any restriction provided that the products

fulfil the requirements given in the certification reference documents which

are freely and publicly available.

The

certification process is based on continuous (yearly) verifications relying on

tests by independent accredited laboratories, factory audits and check of

selection software.

As of today

the ECP mark covers 19 certification programmes in all fields of HVAC&R. It

applies to residential, commercial and industrial products from the residential

air conditioners to the industrial chillers. More than 1 300 tests, 160

factory audits and 100 checks of selection software are carried out every year.

All

certified references and performances are listed in an online directory freely

available (www.eurovent-certification.com). This directory gathers more than

300 certified trademarks and more than 50 000 products.

For each

product category characteristics and certified performances are listed

according to the same data structure and the latest European and international

standards. This allows finding and comparing the certified data easily and with

the assurance that the data have been checked.

The

availability of such database allows to get reliable and exhaustive set of

performances which can be used to assess some trends of the market over time.

As an example the evolution of the energy efficiency of fan coil units can be seen in Figure 1. A Eurovent energy efficiency classification was created in 2011 for these products based on their average energy consumption at three different fan speeds[1]. It can be seen that there is a clear trend towards better energy efficiency as the energy classes are moving from classes E and D to C, B and A.

Figure 1.

Evolution of the distribution of the energy efficiency class for fan coil units

between 2011 and 2015.

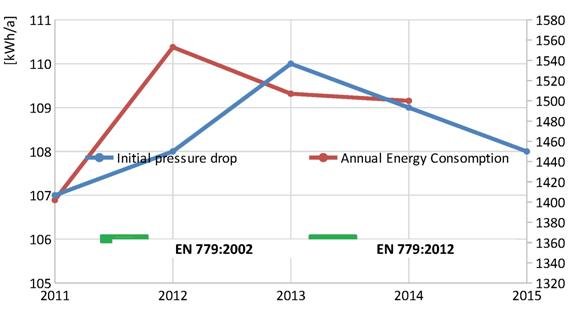

Another

example is the energy efficiency of air filters. For these products a Eurovent

energy classification has been implemented in 2012. This classification is

based on the estimated annual energy consumption derived from the average

pressure drop of the filter[2]. A more classical way to assess the

energy consumption of an air filter is to look at its initial pressure drop. Figure 2 shows the evolution of both the mean initial pressure drop and the mean

annual energy consumption for the certified F7 bag filters of a constant panel

of manufacturers between 2011 and 2015.

Figure 2:

Evolution of the energy efficiency for F7 bag filters between 2011 and 2015.

Unlike what

has been seen for fan coil units the evolution of the mean energy efficiency is

not linear during this period: the energy consumption and the initial pressure

drop increase to reach a maximum in 2013 and then decrease until 2015. This

behaviour can be explained knowing the standardization context behind. A revised

version of the European testing standard was published in 2012 and applied in

the Eurovent certification programme first in 2013. This revised version

introduced stricter requirements for F7 filters related to the discharge

efficiency (see EN 779:2012). In order to fulfil this new requirement

European manufacturers had to improve the filter media in order to increase the

filtration efficiency. As a consequence the mean pressure drop of the filters

increased. After the introduction of the new standard the pressure drop started

to decrease as manufacturers are seeking to propose to their customers more

energy efficient products.

Database of

certified data can be used for many purposes: criteria for tax incentives,

input data for the energy performance calculation of buildings in the framework

of national implementations of EPBD, requirements or input data for building

energy labels and green public procurements, input data for assessing the

energy consumption reduction for white certificates.

As

certified performances provide confidence in the quality and the compliance of

the products, they can be required in voluntary schemes (e. g. building energy

labels, green public procurements, white certificates) or being considered with

an advantage given to certified products over non certified products in

regulatory schemes (e.g. national implementation of EPBD).

An example

of such use can be found in the French building energy performance calculation

method (RT 2012) which applies among others a penalty for non-certified heat

pumps and air-to-air heat exchangers. Approved software for the energy

performance calculation according to this French regulation are linked to

database of products which are fed directly with Eurovent certified performance

data.

The

challenging normative and regulatory background in the fields of HVAC&R

induces a complex environment for all stakeholders. Assessing the quality and

compliance of product performance is therefore more and more difficult for

end-users. In this context the Eurovent Certified Performance online directory

provides an easy and straightforward way to get updated, trustful and

exhaustive data. Such information can be (and is already) used in various

voluntary and regulatory compliance schemes.

![]()

QUALICHeCK

responds to the challenges related to compliance of Energy Performance

Certificate (EPC) declarations and the quality of the building works. Find out

more at http://qualicheck-platform.eu.

The

QUALICHeCK project is co-funded by the Intelligent Energy Europe Programme of

the European Union. The sole responsibility for the content of this article

lies with the author(s). It does not necessarily reflect the opinion of the

European Union. Neither the EASME nor the European Commission are responsible

for any use that may be made of the information contained therein.

[1] For a detailed description of the Eurovent energy efficiency classification for fan coils units, see RS 6/C/002-2015 and RS 6/C/002A-2015 available at www.eurovent-certification.com

[2] For a detailed description of the Eurovent energy efficiency classification for air filters, see RS 4/C/001-2015 available at www.eurovent-certification.com

Follow us on social media accounts to stay up to date with REHVA actualities

0