Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

Emilien ParonSoftware coordinator, |

Pim van den HelmSoftware expert, |

The European Commission

gave a mandate to CEN (mandate 480) to develop a standardized methodology to

calculate the energy performance of buildings (EPB) as required by the

Recast-EPBD 1). Around 50 CEN / ISO standards were developed.

To check the

consistency of the whole methodology it was decided to develop a test software.

For a few well- chosen standards, software modules have been developed and

integrated in a test software tool (the tool and the source code can be

downloaded at: http://dimn-cstb.fr/centool/default.html).

A standard

representation was developed to visualize and check the calculation sequences

between the different modules defined in the standardized methodology. The

sequences are represented by SYSML diagrams and a short description per service

following the overall sequence numbering. The operating condition inputs and

outputs needed for each module to communicate with other modules have been

checked and resumed in tables.

The developed

test software, based on the methodology described in the set of CEN / ISO

standards, shows that the standards could be linked together in a useable

software and that the overall methodology is coherent. The help of the standard

writers was useful and needed to clarify some "grey zones". These

additional information is described in the software tool report [1]. The test software

is delivered with a complex multizoning and multigenerator example test case

using an hourly calculation interval.

To parameter the

example in the test software detailed information on the building components

are needed. Many of these concern the properties of construction elements,

which is the basic information that any EPB calculation method requires. As it

was not the task of the test software to develop user-friendly interfaces, the

usability of the methodology must be increased to be able to apply the EPBD

methodology in practice. User friendly interfaces and links to product data

bases are needed. Several examples already show how the dozens of data needed

to describe for example a heat pump can be reduced to one mouse click.

To bring the

standards to application, the urgent task is now to move from the methodology

to commercial software tools. It is proposed to develop a software kernel, as

it was done in the United States and in France for the national calculation

tools. Commercial software companies could use this kernel as a basis to

develop a complete commercial software tool with user friendly interfaces. This

software kernel could also be used to certify commercial software tools.

The European Commission

gave a mandate to CEN (mandate 480) to develop a standardized methodology to calculate

the energy performance of buildings (EPB) required by the Recast-EPBD[1].

The EPB

calculation methodology has to take into account the characteristics of the

building envelope (insulation, windows, etc.), the characteristics of the

technical systems (heating, cooling, ventilation, domestic hot water, lighting),

the building automation and control systems and the indoor air quality. The

needed standards were developed or updated by different technical committees (CEN:

TC 89, TC 156, TC169, TC 228, TC 247, ISO: TC 163, TC 205). Finally, around 50

standards were developed. This high number is necessary to be able to update

the different standards individually.

The challenge was

to coordinate the technical work of all these committees so that the different

standards fit together in order to be able to calculate the EPB. A technical

committee (TC 371) was created. TC 371 defined a modular structure (see Figure 1) and worked out an overarching standard (EN ISO 52000-1 see [2]) allowing

to reference the whole methodology easily by one reference.

Overarching | Building (as such) | Technical Building Systems | |||||||||||||||||

| Descriptions | Standards | Descriptions | Standards | Descriptions | Heating | Cooling | Ventilation | Humidification | Dehumidification | Domestic Hot water | Lighting | Building automation | Electricity production | |||||

sub1 | M1 | sub1 | M2 | sub1 | M3 | M4 | M5 | M6 | M7 | M8 | M9 | M10 | M11 | ||||||

1 | General | (EN ISO 52000-1 | 1 | General | -- | 1 | General | EN 15316-1 | EN 16798-9 CEN/TR 16798-10 | EN 16798-3 CEN/TR 16798-4 | EN 16798-3 CEN/TR 16798-4 | EN 16798-3 (EN 13779 rev.) CEN/TR 16798-4 | EN 15316-1 | EN 15193-1 | EN 15232 CEN/TR 15232 | ||||

2 | Common terms and definitions; | (EN ISO 52000-1 | 2 | Building Energy Needs | EN ISO 52016-1, | 2 | Needs | EN 12831-3 | prEN 15193-1 | ||||||||||

3 | Applications | (EN ISO 52000-1 | 3 | (Free) Indoor Conditions without Systems | EN ISO 52016-1, | 3 | Maximum Load and Power | EN 12831-1 | EN 16798-11 | EN 12831-3 | |||||||||

4 | Ways to Express Energy | EN ISO 52003-1 | 4 | Ways to Express Energy Performance | EN ISO 52018-1 | 4 | Ways to Express Energy Performance | EN 15316-1 | EN 16798-9 | EN 16798-3 | EN 16798-3 | EN 16798-3 | EN 15316-1 | EN 15193-1 CEN/TR 15193-2 | EN 15232 CEN/TR 15232 | ||||

5 | Building | (EN ISO 52000-1 | 5 | Heat Transfer by Transmission | EN ISO 13789 EN ISO 10077-1 | 5 | Emission & control | EN 15316-2 EN 1500 CEN/TR15500 EN 12098-1 CEN/TR 12098-1 EN 12098-3 CEN/TR 12098-3 EN 12098-5 CEN/TR 12098-5 | EN 15316-2 EN 15500 CEN/TR 15500 | EN 16798-7 EN 15500 CEN/TR 15500 | EN 16798-5-1; EN 16798-5-2 CEN/TR 16798-6-1 CEN/TR 16798-6-2 | EN 16798-5-1; EN 16798-5-2 CEN/TR 16798-6-1 CEN/TR 16798-6-2 | EN 15232 CEN/TR 15232 | ||||||

6 | Building Occupancy and Operating Conditions | EN 16798-1 (ISO 17777-1, ISO/TR 17777-2) | 6 | Heat Transfer by Infiltration and Ventilation | EN ISO 13789 | 6 | Distribution & control | EN 15316-3 CEN/TR 12098-1 EN 12098-3 CEN/TR 12098-3 EN 12098-5 CEN/TR 12098-5 | EN 15316-3 | EN 16798-5-1; EN 16798-5-2 CEN/TR 16798-6-1 CEN/TR 16798-6-2 | EN 15316-3 | EN 15232 CEN/TR 15232 | |||||||

7 | Aggregation of Energy Services and Energy Carriers | (EN ISO 52000-1 | 7 | Internal | See M1-6 | 7 | Storage & control | EN 15316-5 EN 12098-1 CEN/TR 12098-1 EN 12098-3 CEN/TR 12098-3 EN 12098-5 CEN/TR 12098-5 | EN 16798-15 | EN 15316-5 | EN 15232 CEN/TR 15232 | ||||||||

8 | Building Zoning | (EN ISO 52000-1 | 8 | Solar | EN ISO 52022-3 | 8 | Generation & control | EN 12098-1 CEN/TR 12098-1 EN 12098-3 CEN/TR 12098-3 EN 12098-5 CEN/TR 12098-5 EN 15316-4-1 EN 15316-4-2 EN 15316-4-3 EN 15316-4-4 EN 15316-4-5 EN 15316-4-6 EN 15316-4-8 | EN 16798-13 EN 15316-4-2 EN 15316-4-5 | EN 16798-5-1; EN 16798-5-2 CEN/TR 16798-6-1 CEN/TR 16798-6-2 | EN 16798-5-1; EN 16798-5-2 CEN/TR 16798-6-1 CEN/TR 16798-6-2 | EN 16798-5-1; EN 16798-5-2 CEN/TR 16798-6-1 CEN/TR 16798-6-22 | EN 15316-4-1 EN 15316-4-2 EN 15316-4-3 EN 15316-4-4 EN 15316-4-5 EN 15316-4-6 | EN 15232 CEN/TR 15232 | EN 15316-4-3 EN 15316-4-4 EN 15316-4-5 EN 15316-4-7 | ||||

9 | Calculated Energy Performance | (EN ISO 52000-1 | 9 | Building Dynamics (thermal mass) | EN ISO 13786 | 9 | Load dispatching and operating conditions | EN 15232 CEN/TR 15232 | |||||||||||

10 | Measured | (EN ISO 52000-1 | 10 | Measured Energy Performance | - - | 10 | Measured Energy Performance | EN 15378-3 | EN 15378-3 | EN 15193-1 CEN/TR 15193-2 | EN 15232 CEN/TR 15232 | ||||||||

11 | Inspection | - - | 11 | Inspection | (existing standards on IR inspection, airtightness, ...) | 11 | Inspection | EN 15378-1 | EN 16798-17 CEN/TR 16798-18 | EN 16798-17 CEN/TR 16798-18 | EN 16798-17 CEN/TR 16798-18 | EN 16798-17 CEN/TR 16798-18 | EN 15378-1 | EN 15193-1 CEN/TR 15193-2 | WI 00247092 | ||||

12 | Ways to Express Indoor Comfort | EN 16798-1 | 12 | -- | 12 | BMS | WI00247093 | ||||||||||||

13 | ExternalEnvironment Conditions | EN ISO 52010-1 | |||||||||||||||||

14 | Economic Calculation | EN 15459-1 | |||||||||||||||||

Figure 1. EPB standards in the EPB modular structure (EN ISO 52000-1).

To check the

different standards and the consistency of the whole methodology it was decided

to develop a test software.

The control and

consistency check was done in two steps:

1. each

standard itself was checked by an Excel sheet (the

Excel files are publicly accessible via https://isolutions.iso.org/ecom/public/nen/Livelink/open/35102456).

2. for

a few well- chosen standards, software modules have been developed. To prove

the usability of the modular structure (consistency of input, output data) of

the overall methodology a test case was defined.

This second step

is described hereafter.

In the standards,

several calculation intervals and methods are described, for example:

·

hourly,

monthly or even yearly calculation intervals;

·

the

bin method.

For the

consistency check only the hourly method was applied.

The developed tool is an Integrated Test Framework (ITF) that plays the role of the test software where the selected modules interact. It is as such complementary to the individual test required for each module (the earlier mentioned Excel sheets belonging to each EPB-calculation standard).

The software tool

checked the following topics:

·

Consistency

of the calculation sequence and hierarchy of calculations;

·

Availability

of module inputs from the output of some other modules.

The calculation of the energy performance of buildings using the CEN / ISO EPB standards is described in modules (see Figure 1). These modules will interact via the inputs and outputs. The output of one module is the input to another module (or modules). Therefore, the calculation needs to be performed in a specific order (calculation sequence) defined in the standards (overarching standard EN ISO 52000-1 and general standards of each service eg. EN 15316-1 see [3]).

The following general order is determined in the EPB standards:

1. Initialize

EPB calculation

for a building (time independent values module M1-5 and M1-8)

2. Initialize/get

current time interval (calculation intervals) values

a. Occupancy

depending values (M1-6)

b. Climate

data (including solar radiation calculation depending on building model (M1-13)

3. Calculate

the current time interval (uses the indoor climate of the previous time

interval)

a. DHW

I. Needs (M8-2)

II. Distribution (M8-1C, M8-6, M8-9)

III. DHW Storage (M8-7) and DHW instant

production (M (8-8)

b. Lighting

I. Needs (M9-2)

II. Emission (M9-5)

III. Distribution (M9-6)

IV. Generation (M9-8)

c. Ventilation

I. System flow needs => required

flow (M5-5) and flow temperature (M5-6 and M5-8 or M5-5)

II. System flow delivered => supplied

flow and flow temperature (M5-6 and M5-8)

III. All air flows delivered (vents,

windows, leaks and system) (M5-5)

IV. AHU needs (thermal) (M5-6, M5-8,

M6-5, M6-8, M7-5 and M7-8)

d. Thermal conditions

I. Heating and cooling set point

correction (M3-5 and M4-5)

II. Thermal needs (M2-2)

e. Heating (+ DHW for generation part)

I. Emission (M3-5)

II. Distribution (M3-1C, M3-6, M3-9)

III. Storage (M3-7 / M8-7) and Generation

(M3-8 / M8-8)

f. Cooling

I. Emission (M4-5)

II.

Distribution

(M4-6)

III. Storage (M4-7)

IV. Generation (M4-8)

g. (Optionally

repeated if required energy is not supplied) Thermal internal conditions (M2-2)

h. Energy

performance values (Mx-4 and Mx-10)

4. Aggregate

outputs

(consumed energy) of services (M1-7)

Calculate the energy performance of the whole year

(M1-9)

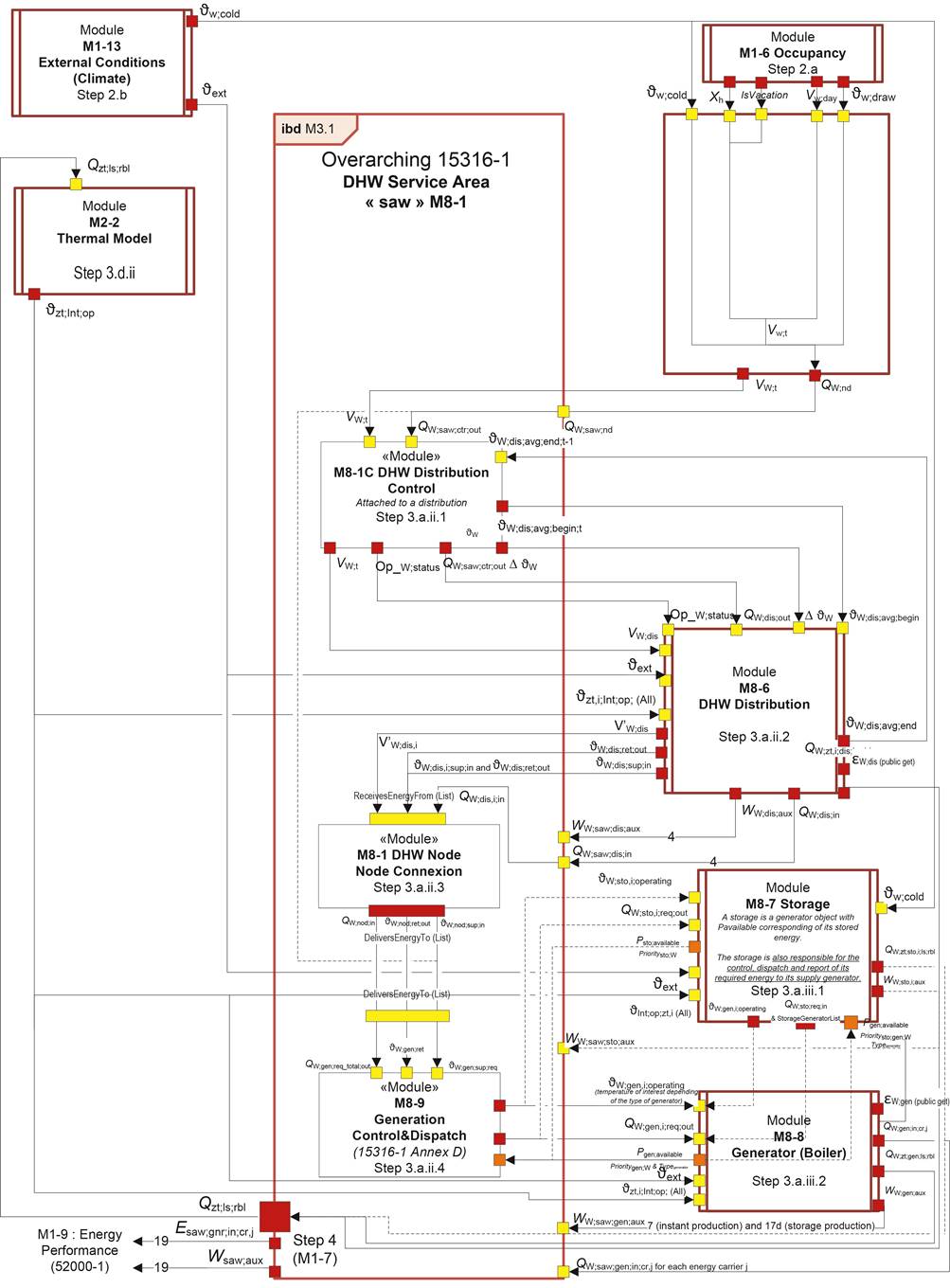

Each service (e.g. heating, cooling) consists of multiple modules exchanging data and which are called in a specific sequence. The software team developed a standard representation to visualize and check the calculation sequences between the different modules defined in the standardized methodology. The sequences are represented by SYSML diagrams and a short description per service following the overall sequence numbering is provided. Hereafter the example of the detailed call sequence for the software implementation of the DHW sequence is presented (Figure 2).

Figure 2. DHW calling sequence.

Based on the module implementation in the ITF and following the calculation sequences, the operating condition inputs and outputs needed for each module to communicate with others modules, have been checked and resumed in tables.

A colour code was set up to indicate the correspondence between the parameters and names in the software and to highlight the missing parameters in the draft standards (see Table 1).

Table 1. Documentation of the input / output data per module.

Description | Symbol | Unit | |

Energy needs for DHW service area at current time

step | QW;nd | kWh | çExisting in the current EPB standard |

Heating emission input in heating service area

sah | QH;sah;em;in | kWh | çExisting in

the current EPB standard but with a different symbol naming. |

Heating authorization for the current time step | IsHeating | Bool | çAbsent in the

current EPB standard or present in equations but forget in the input/output

table |

Total

recoverable heating distribution system losses of the heating service area

sah (for information) | QH;sah;dis;ls;rbl | kWh | çNo need to be put at this level except for information |

Hereafter the example of Module M3-5: Space Heating Emission systems & Control (EN 15316-2) is provided (see Table 2 and 3)

Table 2. M3-5 Space Heating Emission and Control Inputs (Operating Conditions).

Description | Symbol in code | Unit | Comments: | Symbol in the standard | Origin module |

Heating Setpoint temperature in space s | θH;s;set | °C | From Step 2.a | Not present but use

similarly to θint,ini equations | M1-6 |

Heating authorization for the current time step in space s | IsHeating,sp | Bool | From Step 2.a | M1-6 | |

Required thermal energy output of the heating emission system in space

s | QH;s;em;req;out | kWh | Set at Step 3.e.i.1 | Qem;out | M3-1 |

Internal operative temperature of the space | θs;Int;op | °C | Calculate at Step 3.g.(t-1) | θint,ini | M2-2 |

External temperature | θext | °C | Set at Step 2.b | θe | M1-13 |

Table 3. M3-5 Space Heating Emission and Control Outputs.

Description | Symbol in code | Unit | Comments: | Symbol in the standard | Requested by module (receiver) |

Corrected heating Setpoint temperature in

space s | θH;s;set;corr | °C | Step 3.d.i | ”θH;s;set +Dqint;inc” (variation only and not corrected setpoint) | M2-2 |

Heating energy emission input in space s | QH;s;em;in | kWh | Step 3.e.i.2 | M3-1/M3-1C | |

Recoverable heating emission system losses in space s | QH;s;em;ls;rbl | kWh | Step 3.e.i.2 | ”Qem,ls” (total

losses and not recoverable) | M3-1 |

Auxiliary energy of the heating emission system in space s | WH;s;em;aux | kWh | Step 3.e.i.2 | Wem,ls,aux | M3-1 |

Expenditure factor for the heating emission at current time step in

space s | εH;s;em | - | Step 3.e.i.2 | ”εem;ls;an” (annual and not hourly) | NONE – For information (public get only) |

Heating authorization for the current time step in space s | IsHeating,s | Bool | Step 3.e.i.2 | M3-1/M3-1C | |

Nominal power of emitters | Pnom;em | kW | Not a

calculate data but need to be “public get” for other

module | M3-1B | |

Priority of the emitters | Priority | Int | Not a

calculate data but need to be “public get” for other

module | M3-1B |

The software tool team was able to develop the test software based on the methodology described in the set of CEN / ISO standards. This shows that the standards and the overall methodology are coherent.

Of course there is still some fine tuning needed and the help of the standard writers was useful and necessary. This is not surprising taking into account the parallel development of such a huge number of standards in such a short time. Even in calculation software running now since years’ inconsistencies are still identified.

Some of the needed corrections could be changed in the final drafts of the standards, but it was not possible to do it in all cases because some additional discussion would have been needed (for example where which parameter should be calculated, how to take into account Building Automation and Control). Among the main problems faced for example in TC228 standards was also the difficulty to deal with a monthly and an hourly method at the same time, in the same standard, without working out always two separate methods. For the set of EPBD standards the needed additional information to work out a software tool are described in the software tool report [1].

To prove the usability of the modular structure, the software tool is delivered with an example test case (project.xml). The software team used the TC 89 team's test case example for the building energy needs as described in EN ISO/TR 52016-2 (single family house) and added the different service systems (heating, DHW, etc). The sizing of these systems is not perfect as it was done only approximately and this is reflected in the results. The precise value of each output is not so important as the example test case was used in prior to validate the correct implementation of modules and the overarching sequence in the software tool.

The example test case was transformed to a multi-zone example in order to test the most complex case. The building is on two levels; each level corresponds to a thermal zone (multi-zone case). The service areas are crossing both thermal zones.

The case represents a stand-alone house with a total of 176 m² net heated areas and 483 m³ net volumes. The house is assumed to be located in the centre of France (Allier – 03).

The house is occupied by 4 working people (outside of the house during the day and on holidays all August), consuming each 40 litres of DHW per day, distributed equally through the house (for internal gains calculation in both zones).

The heating is active only between the beginning of October and the end of April. Outside this period, the pump and circulation for heating are "Off". Inside this period, even without any needs, the pump and the heating loop circulation are "On", consume energy and have losses. Each level is equipped with water based heat emitters of 7000 W total capacity and electrical back-up emitters with 2000 W total capacity (multi- emitter case).

The DHW and heating needs are provided by the same two service condensing boiler (with “after 1994” EN15316-4-1 default parameters) with 28 kW capacity and located in level 1 (Thermal Zone 1) of the house.

The detailed XML description of this test case example is described in the software final report [1]. An extract is provided in Table 4 hereafter.

Table 4. Example Test Case XML (extract).

<?xmlversion="1.0"encoding="utf-8"?> <Projectxmlns:xsi="http://www.w3.org/2001/XMLSchema-instance"xmlns:xsd="http://www.w3.org/2001/XMLSchema">

<Index>1</Index>

<Name>Project1</Name> <Description>Desc</Description> <Buildings> <Building> <Index>1</Index> <Name>Building 1</Name> <Description>Desc</Description> etc |

The software tool summarizes the results of the example test case (see Table 5) with the connected modules, except for ventilation for which a simplified model has been used.

Table 5. Resume of outputs (example).

NEEDS | TOTAL DELIVERED ENERGY | TOTAL PRIMARY ENERGY | |||||||||

Area (m²) | HeatingNeeds | CoolingNeeds | DHWNeeds | Heating | Cooling | DHW | Heating | Cooling | DHW | ||

building1 (kWh/m²) | 176.8 | 23.74 | 0.00 | 9.76 | 37.59 | 0.00 | 23.50 | 48.47 | 0.00 | 25.90 | |

Thermal zone1 (kWh/m²) | 91.8 | 26.76 | 0.00 | ||||||||

Thermal zone2 (kWh/m²) | 85 | 20.48 | 0.00 | ||||||||

SAH1 (kWh/m²) | 176.8 | 23.74 | 37.59 | 48.47 | |||||||

SAW1 (kWh/m²) | 176.8 | 9.76 | 23.50 | 25.90 | |||||||

More detailed outputs can also be provided.

The time needed for the calculation, based on an hourly time interval depends on the system modules used, the amount of data to read and write. On a i7-4810MQ 2.8GHz processor it took approximately 1 minute to calculate a whole year including an additional initialization month. This is reached even without using multithreading technology and any other optimization to speed the process.

The example test case confirmed that even for complex cases using an hourly calculation interval it is possible to develop and run a software based on the set of EPBD standards.

This type of tools is needed for example for the European Voluntary Certification Scheme for non- residential buildings and for high performing buildings as nearly-zero energy buildings.

The tool and the source code can be downloaded at http://dimn-cstb.fr/centool/default.html

The software team developed a test software with a few well-chosen modules to check if the standardized methodology of the EPBD standards is consistent and can be applied in a running software tool.

It is to be remembered that it was not the task of the software tool team to develop user friendly interfaces or a commercial software tool.

To parameter the example in the test software detailed information on the building components are needed. Many of these concern the properties of construction elements, which is the basic information that any EPB calculation method requires. As it was not the task of the test software to develop user-friendly interfaces, the usability of the methodology must be increased to be able to apply the EPBD methodology in practice. User friendly interfaces and links to product data bases are needed. Several examples already show how the dozens of data needed to describe for example a heat pump can be reduced to one mouse click.

There are several possibilities to develop such a software by the market. For example, the market could develop the complete software starting from the methodology, or the market could focus on the development of the user interfaces. For the American "Energy plus" software and the French RT2012 the State authorities financed the development of a kernel (focusing on the methodology) and provided it for free to the software developers to develop and commercialize a user-friendly commercial software. The French kernel was worked out by the people involved in the development of the methodology (the standard writers) with the assistance of software professionals. This solution is very efficient because there is no need that each software developer analyses the thousands of pages of the standards. This approach helps to assure that the kernel is completely in line with the methodology and vice versa and that the updating of the methodology and the kernel is coordinated.

This approach has also the big advantage to favour the dissemination of the method.

A software kernel is needed in any case as reference to set up the test procedure for the certification of the commercial software.

The software tool team confirmed that the tested EPBD modules are software proofed and consistence.

The urgent task is now to move from the methodology to commercial software tools to bring the standards to application.

It is proposed to develop a software kernel, as it was done in the United States and in France for the national calculation tools. Commercial software companies could use this kernel as a basis to develop a complete commercial software tool with user friendly interfaces. This kernel could also be used to certify the commercial software.

[1] CEN/TC 371 N 513; Software Tool Team - Final Deliverable - 2016-07-19;

[2] ISO/FDIS 52000-1; Energy performance of buildings — Overarching EPB assessment – Part 1: General framework and procedures; Heating systems and water based cooling systems in buildings — Method for calculation of system energy requirements and system efficiencies — Part 1: General and Energy performance expression

[3] FprEN 15316-1; Heating systems and water based cooling systems in buildings — Method for calculation of system energy requirements and system efficiencies — Part 1: General and Energy performance expression

[1]EPBD: DIRECTIVE 2002/91/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL

of 16 December 2002 on the energy performance of buildings.

Recast-EPBD: DIRECTIVE

2010/31/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 19 May 2010 on the

energy performance of buildings; (recast).

Follow us on social media accounts to stay up to date with REHVA actualities

0