Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

Meanwhile, the costs for electricity, exception made for some nations with prevailing production of nuclear energy, has risen drastically.

Furthermore, all EU countries have subscribed the Tokyo protocol and the later COP-23 Paris agreement on Climate Change and additional restriction on CO2 emissions have been recently agreed by EU Member States.

This analysis, which considers the performance of liquid chillers equipped with the two traditional condensing systems (water and air), is aimed at a realistic comparison between the two systems in energetic and economical terms.

This presentation shows that water condensing systems, in spite of all the related issues (which however can be solved), are more efficient than air condensing systems, both in terms of energy consumption and of pollution.

· This analysis compared two liquid chillers sizes: 600 & 1200 kW capacity, air cooled and water cooled via tower.

· Two climate conditions were assumed, in order to gather a comprehensive perspective:

• Continental

(air: D.B. +28°C, tower water: W.B. +18°C);

• Mediterranean:

(air: D.B. +35°C, tower water: W.B. +25°C).

· Spring/autumn operation were simulated, 1800 hours running, typical of building office applications in European installations.

· High efficiency chiller units, two screw compressors each, two independent refrigerant circuits, dry expansion evaporator were considered in order to avoid any possible comparison errors.

· For a correct evaluation, water cooled chiller absorbed power also included inverter assisted tower fan motor and condenser pump.

The energy efficiency analysis was based on EER and ESEER calculations.

The IPLV and ARI standards mentioned were not taken into consideration, since they aren't applicable in the EU.

·

EER (Energy Efficiency Ratio):

this parameter defines the energy efficiency of liquid chiller under standard

conditions, normally available in any chillers technical catalogue;

·

ESEER (European Seasonal Energy

Efficiency Ratio):

it defines the average seasonal energy efficiency under the four load

conditions and with decreasing air/water temperatures to condenser. If not

listed in the catalogues it can be calculatedby implementing in Equation 1 the

data displayed in Table 1.

Table 1. ESEER calculation basis.

Load and temperature conditions: | ||||

Chilller | Condens.

ambient air | Tower

water |

| EER |

100 | 35 | 30 | ||

75 | 30 | 26 | ||

50 | 25 | 22 | ||

25 | 20 | 18 | ||

ESEER = | 3 EER100%

+ 33 EER75% + 41 EER50% + 23 EER25% |

100 |

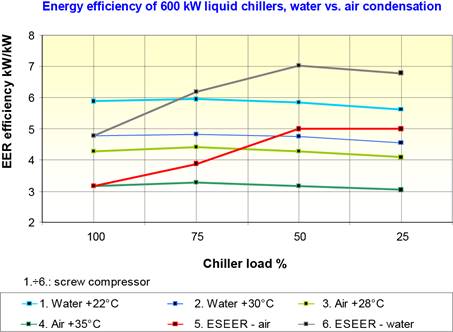

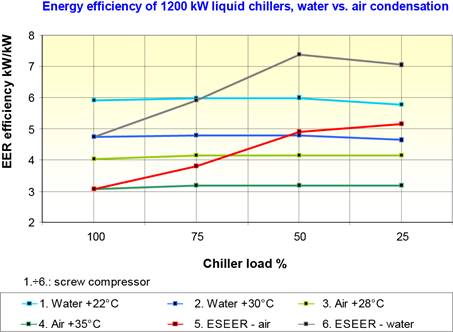

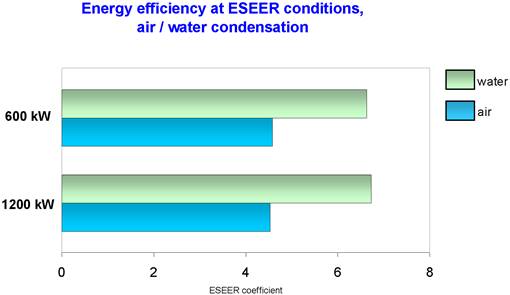

As shown in Figures 1 and 3, a huge difference among water and air-cooled condensers is evident in terms of efficiency, with the ESEER ranging from approximate 5 to 7/7.4. The graphs clearly display that water cooled chillers are more efficient than air cooled chillers.

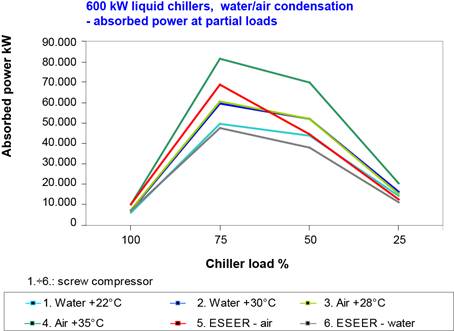

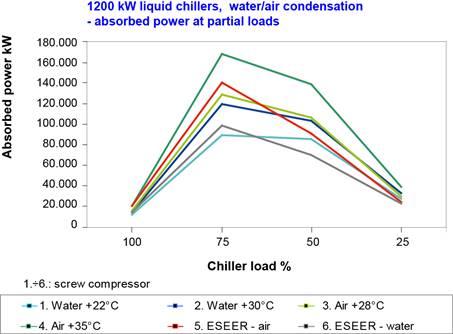

There is also an evident difference between the grey and red line in Figures 2 and 4, and the area between the two lines represents a considerable difference of consumption in favour of water cooled chiller systems.

Figure 1. Energy efficiency of 600 kW liquid chillers: with water and air-cooled condensers.

Figure 2. 600 kW liquid chillers, absorbed power at partial loads for water and air-cooled condensers.

Figure 3. Energy efficiency of 1200 kW liquid chillers with water and air-cooled condensers.

Figure 4. 1200 kW liquid chillers, absorbed power at partial loads for water and air-cooled condensers.

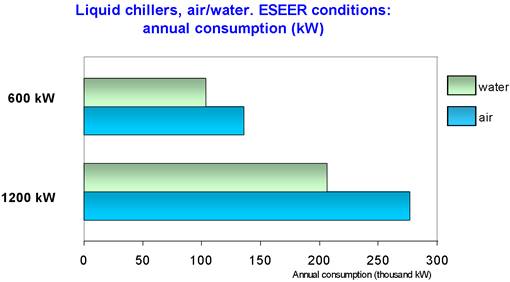

Figure 5. Annual consumption in MWh of two liquid chillers with air and water-cooled condensers.

Figure 6. ESEER’s of two liquid chillers with air and water-cooled condensers.

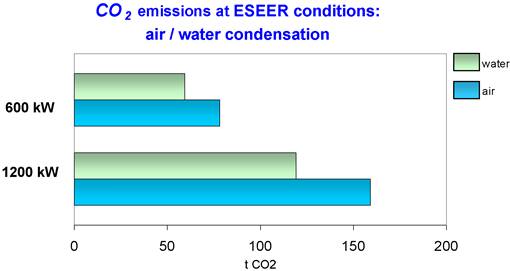

Figure 7. CO2 emission compared at ESEER conditions for the two liquid chillers with air and water-cooled condensers.

Table 2. Cost comparison.

600–1200 kW

liquid chillers, water vs. air – Economic comparison

Description | Price (€) | |

600 kW | 1200 kW | |

1. Cooling tower | 10,800 | 18,000 |

2. Piping, filters, valves… | 3,900 | 7,800 |

3. Condenser water pumps | 2,100 | 4,200 |

4. Water treatments, bleed-off… | 7,100 | 8,500 |

5. Inverter control panels for tower and pumps | 2,700 | 4,100 |

6. Electric cable cost reduction | -4,000 | -5,000 |

TOTAL | 22,600 | 37,100 |

7. Water condensed liquid chiller | 44,200 | 84,500 |

TOTAL (1÷7) | 66,800 | 121,600 |

8. Air cooled chiller | 58,500 | 107,250 |

(A) Water-air cost difference | 8,300 | 14,350 |

(B) Water-air consumption difference (kWh

33490/69765) x 0.15 €/kWh | 5,023 | 10,465 |

(A-B)

R.O.I. = Return on Investment (years) | 1.65 | 1.37 |

To avoid any possible misunderstanding, it must be highlighted that the values shown in the charts are referred to different calculation methods:

· EER values (operation with water and air) are at constant temperatures and different from the ESEER ones;

· There’s no liquid chiller operating under these conditions, as both air and water continuously vary during the day, the months and the year;

· Such information, shown in any commercial catalogue, can lead to assessment mistakes, as it doesn’t represent the chiller real working conditions, which depend on the effective ambient situation;

·

ESEER values are to be applied for

a correct technical selection.

For energy calculations hourly based (bin method) calculation procedures as

described in the EPB standard EN16798-13 “Energy performance of Buildings, part

13: Module 4-8 Calculation of cooling systems - Generation” should be used to

calculate the expected yearly energy use and connected CO2

emission.

The analysis of performance, consumption and energy efficiency shows a big difference between water condensed and air cooled liquid chillers.

The substantial differences are the annual electricity saving (kWh/year) and consequently the less CO2 emissions into the environment. (see Figures 5–7).

The use of water condensed liquid chillers shows an evident economical advantage (faster R.O.I). Furthermore, as the average plant life is over 15 years, the total saving can be easily assessed. (see Table 2).

Moreover, the installation of water condensed liquid chillers is strongly suggested both to comply with Tokyo protocol and with the 20-20-20 target prescribed by European Union.

Last but not least, some final considerations:

· The use of air cooled chillers requires less design effort than that of chillers/cooling tower system. Obviously, designers tend to adopt the solution which is easier for them…

·

In addition, one of the most

popular reasons used is the issue concerning “Legionella risks”, however this

is often an excuse only, as current technologies make it possible to control

and avoid this problem in the chiller/tower system. However a stringent

maintenance protocol is required and any airborne water particle spills from

the cooling tower shall be prevented.

The “Legionella risks” problem is much more serious in air handling units,

because air is supplied (and breathed!) to the buildings such as in hospitals,

schools, offices etc.

Nevertheless, this issue is often underestimated or neglected.

1. Mozzato S. – "Energetic efficiency of HVAC plants" conference – Milan, Sept. 22, 2009.

2. Montrasio P – "Cooling tower application", internal documentation.

Follow us on social media accounts to stay up to date with REHVA actualities

0