Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

|

|

Ilse Jacobs | Marcel Loomans | Lada Hensen-Centnerová | Michel Krombeen | HeliantheKort |

Eindhoven University of Technology, Department

of the Built Environment, Building Performance group, Eindhoven.ilse-jacobs@hotmail.com | Eindhoven University of Technology, Department

of the Built Environment, Building Performance group, Eindhoven.m.g.l.c.loomans@tue.nl | Eindhoven University of Technology, Department

of the Built Environment, Building Sustainability group, Eindhoven.l.hensen@tue.nl | Unica, Bodegravenm.krombeen@unica.nl | Eindhoven University of Technology, Department

of the Built Environment, Building Performance group, Eindhoven.h.s.m.kort@tue.nl |

In an

operating theatre, the most important requirement is that the patient receives

the best possible care during surgery. The assumption is that by efficiently

supplying sufficient clean air into the room the occurrence of post-operative

wound infections will be minimized. Therefore, the design of an operating

theatre is mainly based on air quality for contamination control (see Figure 1).

In case of an operating theatre, the possible sources of pollution are the

surgical staff, the surgical instruments and the patient itself. Because, based

on these sources, the amount of air that needs to be supplied is considerable

(in an operating theatre the air change rate is in the order of 15-30 h-1

[1]), theoretically efficient unidirectional downflow (UDF) ventilation systems

are often chosen over mixing systems.

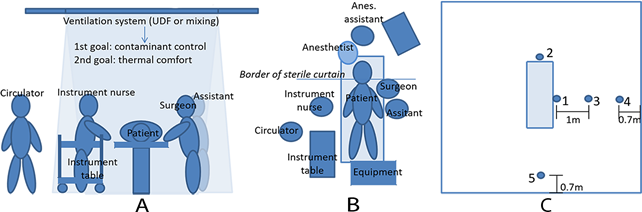

Figure 1.

View and plan of a typical operating theatre with a downflow-based ventilation

system [1A, 1B]. Figure 1C gives an impression of the typical positions of

the surgical team members (1=surgeon/assistant, 2=anesthetist,

3=instrument nurse, 4/5=circulator), where positions 1-3 are often positioned

in the direct influence of the downflow system.

Until 2014,

The Netherlands prescribed a UDF system for class I operating theatres, i.e.

highest air quality requirements. After 2014, a more performance-driven approach

was chosen which made it possible to look beyond conventional systems, offering

possibilities for new design solutions. In the entire discussion about the

quality of an operating theatre, the effect of the work environment of the

surgical staff on the result of an operation is generally overlooked. Good

lighting is self-evident and translated, e.g., into operating lamps.

Sound/speech intelligibility is a point of attention, but also thermal comfort

plays an important role in achieving an optimal work environment. This study

focused on the latter aspect. Some earlier research is available [2] and

literature also shows some numerical analysis of the thermal conditions in an

operating theatre [3]. The objective of this research was to analyze the performance of existing operating theatre

ventilation systems and new developments in this field with respect to thermal

comfort, and identify which system(s) may be preferred from a thermal comfort

point-of-view.

Figure 2. UDF (2T) [left] – Opragon [middle] – Halton [right].

As part of

the research is perception based, and limitations in the numerical analysis are

significant the work is performed experimentally. In the study, in-situ

measurements have been performed in several operating theatres with different

types of ventilation systems (see Figure 2 for an

impression). The systems studied are UDF (two-temperature [2T]

system), Opragon and Halton. The measurements have

been carried out in operating theatres in two different hospitals (UDF 2T, Opragon) and in two mock-ups

of an operating theatre at the relevant manufacturers of the systems (Avidicare [Opragon] in Sweden;

Halton in Finland). Thermal comfort measurements were derived according to ISO

7730 [4] (Predicted Mean Vote [PMV]/ Predicted Percentage of Dissatisfied [PPD]).

Additionally, non-uniform thermal comfort conditions (draught, vertical

temperature gradients, floor temperature and radiant asymmetry) have been

determined. Where possible, the measurements have been carried out for three

different use situations:

1. No subjects in the room,

2. Under static conditions (i.e. real persons

in fixed positions, or represented as heat sources),

3. Under dynamic conditions (i.e. real persons

moving around as if a real surgery is performed).

Reproducibility

of the measurements has been tested by performing similar measurements for

equal boundary conditions. The results show that DPMV ≤ 0.1 and the draught rate and

vertical temperature gradient were within the accuracy level of the applied

sensor.

In addition

to the objective measurements, subjective analysis has been performed through

online surveys on thermal comfort perception of surgical staff members during

surgeries. General thermal comfort was examined, but also non-uniform thermal

conditions such as draught. For these surveys use has been made of literature

[2][5]. This subjective analysis was performed parallel to the experimental

research.

For the

subjective part of the research, 42 Dutch hospitals (out of 81) were approached

to participate in the study. In total, 12 hospitals eventually cooperated and

survey results of 341 participants (surgical staff members) were collected. All

members of an operating team were represented in the response, while UDF

(one-temperature [1T]/2T plenums in particular) was present as a system. For

the statistical analysis of the data SPSS Statistics 25 has been used.

Significance is assumed at p < 0.05. Further

details of the research can be found in [6].

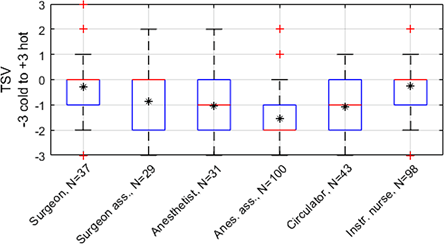

Subjective data - An example of the subjective results of the

survey is shown in Figure 3. There is a difference in

perception of the thermal conditions between the members of the surgical team.

One can derive that, on average, the staff members are feeling cold, with the anesthesiology assistant being significantly colder than

the other members.

Figure 3.

Survey results – uniform thermal comfort. The TSV (Thermal Sensation Vote) is

an index on the 7-point thermal sensation scale ranging from -3 (cold) to +3

(hot) with 0 as neutral.

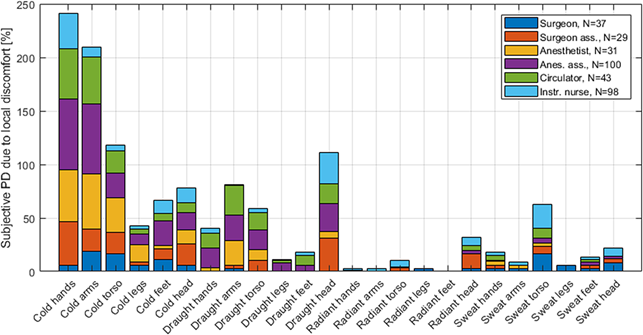

In case of

non-uniform thermal comfort, the differences are less pronounced (Figure 4).

In general, hands and arms are often perceived as cold as a result of draught.

The surgeon generally has fewer complaints. The anesthesiology

assistant has significantly more complaints in comparison to the other members

of the surgical team.

Figure 4.

Survey results – non-uniform thermal comfort. The surgical staff members are

subdivided per function and were able to give multiple answers regarding local

discomfort. Therefore, the total percentage of dissatisfied people can exceed

100%.

The effect

of the type of ventilation system on the assessment of the general thermal

sensation and acceptance does not show any significant differences. Every type

of ventilation system seems to have its own specific complaints with respect to

local discomfort. But these differences are not significant based on the

available data. In the survey three different type of ventilation systems were

compared: 1T plenum (N=72), 2T plenum (N=165) and Opragon (N=24).

Comparing

the subjective data with theory, an assessment can be made of the extent to

which the existing ISO7730 standard is applicable to the operating theatre (Figure 5).

It is assumed that the outcome for the TAV (Thermal Acceptance Vote) is

representative for the degree of dissatisfaction (PD: Percentage of Dissatisfied

people).

|

|

|

Figure 5. Subjective perception versus the percentage of

dissatisfied persons [PD] and a comparison with the theory (A: all members of

the surgical team together; B: subdivided by function) [3]. |

The results

show that in case of the operating theatre the theory underestimates the number

of satisfied people. The subjective results do show the same trend as the

theoretical model. The individual results per team member show that there are

clear differences in thermal perception (Figure 5B).

Preferences are both on the cool and on the warm side. This clearly shows the

complexity of the problem in the design of such systems.

Objective data – The comparison of the objective data

(measurements) for the different systems (at an average set point temperature

of 20°C) shows that the PMV (Predicted Mean Vote) ends up on the cold side (≈−1)

of the thermal sensation scale. The systems that are studied show little

differences. The variation is also comparable for each position where

measurements took place (see Figure 1C). The anesthesiology assistant (position 2 and 4) has the

worst thermal sensation (lowest PMV value). For the instrument nurse (position 3)

the situation is somewhat better based on the PMV value. With regard to local

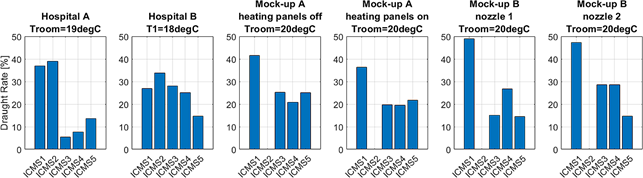

discomfort, especially draught is a problem (see Figure 6).

The positions under the ventilation system are most critical, although at

Hospital B the differences with the other positions are not significant. The

vertical temperature gradient and floor temperature pose little or no problems.

Figure 6.

Theoretical percentage of draft complaints (PD) based on objective measurements

for the different positions in an operating theatre (see Figure 3) with

different types of systems and conditions (For Opragon and Halton it was not

possible to measure at position 2 [ICMS2] due to a non-functioning

sensor).

Comparing

the measurements results for the draught rate (DR) with the subjective (survey)

data, it is noticed that the surgeon has few draught complaints (position ICMS1),

while the measured data indicates otherwise. Referring to the survey results,

the Opragon system also shows more draught complaints

compared to the other systems (DROpragon= 46% compared to DRUDF_T1 = 36% and DRUDF_T2 =

34%). This is not reflected in the measurement results (DROpragon

= 25% compared to DRUDF_T2 = 24%).

The results

provide interesting insights into the current situation in operating theatres

in the Netherlands with regard to thermal comfort of the surgical team. These

results show that improvement is possible and desirable for better thermal

conditions. Although no statement can be made about the effect on work

performance, it may be suspected that in line with what is known about the

office environment [7], this performance is affected by thermal comfort. In

this case, work performance must be translated in the quality of the execution

of the surgery. This could be one of the reasons why, in theory, more efficient

systems (based on air quality) perform less than expected [8].

The results

of the survey indicate that there are fewer complaints than theory suggests

based on the average thermal sensation (PMV). This is not in line with the

hypothesis that people would be more critical since the adaption possibilities

in an operating theatre are limited. It may be assumed that the focus on the

patient makes the own thermal comfort a bit more subordinate. If that is the

case, it is questionable whether that is a good choice. However, the PMV model

has been developed especially for an office environment [4]. At individual

level (member of the surgical team) the agreements are better. This is in line

with the results from Van Gaever et al. [2].

Draught

perception is experienced differently in an operating theatre than theory

indicates. The measurements show high percentages of draught complaints,

especially underneath the plenum. The subjective data show, however, that the

surgeon has almost no draught complaints. Contrary, other members clearly show

more draught complaints than the measurements (and therefore theory) suggest.

The different systems show some differences in the evaluation of draught, but

generally reveal the same pattern with higher values underneath the plenum.

The

limitations in the research must also be mentioned. Clothing and metabolism

have an important effect on the PMV values. No specific data were available for

surgical staff and, on top of that, the survey showed that there were clear

differences in clothing levels between the different hospitals. Additionally, a

standard operating theatre with a standard setup has been assumed during the

research. In combination with information from literature, clothing insulation

(Icl)

and metabolism (M) have been set for the different

members of the surgical staff (Icl = 0.5 – 0.69 clo;

M = 1.5 – 1.6 W/m²). This may not be applicable

for specific surgeries. Furthermore, it is assumed that some survey questions

were not interpreted correctly in a few cases. If misinterpretation was assumed

based on the response to the other questions, the results were excluded from

the analysis.

The

measurements could not be performed simultaneously with an actual surgery due

to hygienic reasons. The location of heat sources and settings of the operating

theatre were somewhat limited by the applicable rules. Besides, it was not

feasible in this study due to limitations of the reserved research time, to

perform measurements for all three use situations in all variants. For those

cases where this was possible, measurement situation 2 (static) and situation 3

(dynamic) led to similar conclusions in terms of thermal comfort.

This

research shows that the thermal comfort in operating theatres for the members

of a surgical team is perceived as not optimal. The distinction in perceived

satisfaction for the different members is also evident. Application of the

theoretical PMV and DR models needs further attention when applied for

operating theatres. Future research may focus on this issue.

The direct

effect of thermal (dis)comfort on the outcomes of a surgery is unknown since

specific information for the operating theatre is missing. However, it seems

appropriate to give this aspect a more prominent role in the development of

ventilation systems for operating theatres than has been the case until now.

Disconnecting the air quality issue about the thermal issue seems to be an

interesting option in order to find an optimal combination about both aspects

[9].

Possible

improvements can also be found in clothing adjustments. It is expected that the

possibility of covering arms, hands and neck against cold and draught will

contribute positively to the thermal sensation of the individual staff members.

In all cases, the most important goal remains the health and safety of the

patient. In an operating theatre, there is little discussion about this.

This

investigation would not have been possible without the hospitals and the

operating staff who cooperated in this investigation. This also applies to Avidicare, Optimus and Halton, who made their facilities

available for carrying out measurements. Finally, a word of thanks to the BPS

laboratory of the TU/e, and especially Wout van Bommel, for preparing the measurements and the associated

measuring equipment.

The whole

report can be found here: https://pure.tue.nl/ws/portalfiles/portal/108242086/Jacobs_0815645.pdf

[1] Gormley, T., Markel, T.A.,

Jones, H.W., Wagner, J., Greeley, D., Clarke, J.H., Abkowitz, M., Ostojic, J. (2017). Methodology for

analysing environmental quality indicators in a dynamic operating room

environment. American Journal of Infection Control 45, pp. 354-359.

[2] Van

Gaever, R., Jacobs, V.A., Diltoer,

M., Peeters, L., Vanlanduit,

S. Thermal comfort of the surgical staff in the operating room. Building and

Environment 81, pp. 37-41. 2014.

[3] Sadrizadeh S, Loomans MGLC. Thermal comfort in hospital

and healthcare facilities: a literature review. In IAQVAC 2016, the 9th

International Conference on Indoor Air Quality Ventilation & Energy Conservation

in Buildings, 23-26 October 2016, Seoul, South Korea. s.l.:

s.n.2016. p. 1-12. 1049. 2016.

[4] International Organization

for Standardization (ISO). NEN-EN-ISO 7730: 2005. Ergonomics of the thermal

environment – Analytical determination and interpretation of thermal comfort

using calculation of the PMV and PPD indices and local thermal comfort

criteria. 2005.

[5] Ottenheijm, E.M.M., Loomans,

M.G.L.C., Kort, H.S.M. & Trip, A. Thermal comfort

assessment in a Dutch hospital setting – model applicability. Proceedings of

the 14th International Conference on Indoor Air Quality and Climate. Gent, België. 2016.

[6] Jacobs, I.M. Thermal comfort of surgical

staff in operating rooms with different types of ventilation systems A study

towards design solutions for optimized thermal conditions. Master graduation

thesis. Eindhoven University of Technology. Department of the Built

Environment. Mastertrack Building Physics and Services.

Eindhoven. pp. 148. 2018.

[7] REHVA. Indoor climate and

productivity in offices. Guidebook No.6. Federation of European Heating,

Ventilation Associations. 2006.

[8] Allegranzi, B., Zayed, B. Bischoff, P. et al. New WHO recommendations on

intraoperative and postoperative measures for surgical site infection

prevention: an evidence-based global perspective. Lancet Infectectious

Diseases. Published online November 2nd 2016.

(http://dx.doi.org/10.1016/S1473-3099(16)30402-9).

[9] Loomans, M. G. L. C., de Visser, I. M., Loogman, J. G. H., Kort, H. S. M.

Alternative ventilation system for operating theaters:

parameter study and full-scale assessment of the performance of a local

ventilation system. Building and Environment. 102, pp. 26-38. 2016.

Follow us on social media accounts to stay up to date with REHVA actualities

0