Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

Eurovent

chiller program introduced the first energy label for chiller based on energy

efficiency restricted until that moment to household appliances in the

regulation. The classification scheme follows the A to G approach used in the

European Energy Labeling regulations for household appliances while the class’s

thresholds were defined and revised by the participants to promote energy

efficient products, phase out non- efficient products and incentivize

development.

The

seasonal efficiency ratio presents another effort from Eurovent and the chiller

certification program participant's to provide simple and representative

selection criteria to help the purchaser choose more efficient products.

Efficiency at standard conditions and energy labeling are great tools to select

efficient products but they only reflect the efficiency of the product under

standard conditions at full load which is practically insignificant over the

real operating conditions of the product. The European Seasonal Energy

Efficiency Ratio (ESEER) is a weighed formula enabling to take into account the

variation of EER (Energy Efficiency Ratio) with the load rate and the variation

of air or water inlet condenser temperature as follows

ESEER=A × EERA + B × EERB + C × EERC + D × EERD

Where

Conditions | Load

Ratio % | Weighing

coefficient | Air temperature at condenser inlet (air

cooled chillers) | Water temperature at condenser inlet (water

cooled chillers) |

A | 100 | 0.03 | 35 | 30 |

B | 75 | 0.33 | 30 | 26 |

C | 50 | 0.41 | 25 | 22 |

D | 25 | 0.23 | 20 | 18 |

Although

the ESEER methodology is inspired by ARI IPLV[1],

the conditions and the weighing coefficient were determined after a study for

European climate and European buildings.

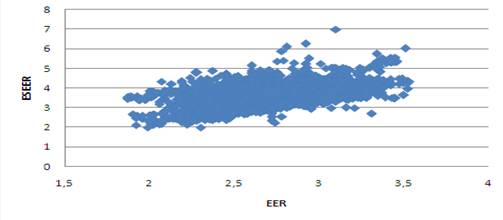

As shown in

Figure 1 the discrepancy between Energy Efficiency

ratio at nominal condition and the ESEER, and the fact those units with the

similar EER have different values of ESEER summarize the added value of this

approach. The ESEER should be the primary criteria to select a unit with better

performances at operating temperature conditions and part load.

Figure 1. ESEER vs. EER Eurovent 2012

certified data for air cooled chillers

The ESEER is

largely embraced by the market and become recognized as a major selection

criterion. The ESEER certification also constituted experience that helped

during the study for Ecodesign[2]

regulation Lot 6 especially for determination of minimum energy efficiency

requirement and possible threshold for labeling.

A revision

of EN14511 was ratified on the 19th of July 2011 and published beginning of

2012. The new version of EN 14511-2011 advocates that the efficiency of the

pump whether it is an integral part of the unit or not is a function of its hydraulic

power instead of the default value.

Historically

chiller performances were certified as “gross” values measured when the pump is

not running for units with integral pumps. This choice was made as the previous

methodology (using a default value) was unrealistic and penalizing especially

large units.

As this

method is more realistic, the chillers program participants decided to fully

apply this new version starting from the 2012 certification campaign. The new

performances declared based on this new version of the standard were published

on the ECC website by March 2012.

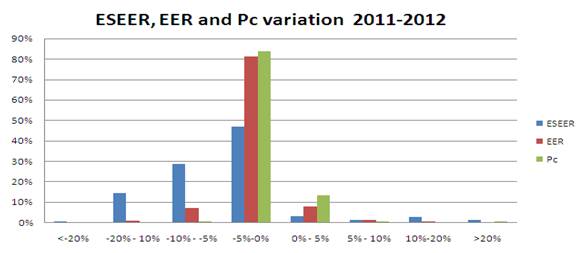

As shown in

Figure 2 a significant difference between thermal

performances (Cooling/Heating capacities, EER/COP and ESEER) published

according to EN 14511:3-2011 and those certified during the previous campaigns

(calculated according to EN 14511:3-2007 with exception of heat exchanger

pressure drop & water pump efficiency) can be observed.

Eurovent

also advocates for the adoption of the same mythology for Fan’s as minimum

efficiency are already defined in the regulation 327 for lot 11. This approach

will guarantee harmonization between the different EupLots[3]

and to have a better transcription of the real performance of the unit.

Under

Ecodesign Directive chillers are affected by 3 studies which are Lot 1 Boilers

and combiboilers, ENTR Lot 1 Refrigerating and freezing equipment and ENTR[4]

Lot 6 Air-conditioning and ventilation systems. The Eurovent product group for

chillers heavily participated in the work done for these lots through position

papers, meeting with the consultants in charge of the preparatory study and

participation in the stakeholders meeting. Eurovent help bringing accurate data

and information about the state of the art of chiller industries and the

forecasted technological developments in this field. The work done by Eurovent

certification on the development of a seasonal energy efficiency ratio in

cooling and later on in heating (ESCOP[5]

project) helped pinpoint the different challenges for the instituting such

factors. The certification committee for chiller also started working by

creating a technical committee in order to tackle the different issue for

starting the certification of performances required by the regulation that will

emerge from the lots sited above.

Making the

certified data easy available for consumer and consultant was always a priority

for Eurovent. Our interactive web site, created since the launching of the

company helps bring reliable data. In addition to the certified data a

dedicated description page for each certification program containing the outlet

of the program, definitions and rating conditions is made accessible and

constantly updated to help visitors understand the value and the consistency of

the certified data.

In 2009

Eurovent launched a widget called Certiflash designed as a service bringing

added value to the community of consultants, design engineers, specifiers,

architects, buyers, contractors, developers looking for quick and real-time

access to HVAC products data and to get individual certificate for HVAC

products.

Available

on the three popular web browsers and on iPhone, Blackberry and Android mobile

phones, Certiflash is the guarantee to have a permanent access to certified

data and to generate individual certificate that can be used to complete

applications for local incentive scheme or to obtain a building energy

performance rating.

Eurovent is

also part of a project called CLE@[6]

that aims to feed on a regular basis numerous building thermal/energy simulation

software. By doing so, Eurovent certified products and associated performance

data are imbedded and directly used in building calculation engines which is

very helpful to consultant at the stage of product selection. This project

comes as a response for the implementation of EPBD directive in different EU

countries (RT 2012 in France) that requires the declaration of an important

amount of performances.

[1] ARI IPLV” : Integrated Part Load Value by AHRI [reference : AHRI Standard 550/590 (I-P), see http://www.ahrinet.org/App_Content/ahri/files/standards%20pdfs/AHRI%20standards%20pdfs/AHRI%20Standard%20550-590%20%28I-P%29-2011.pdf]

[2] Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 establishing a framework for the setting of ecodesign requirements for energy-related products (recast).

[3] “Eup Lots” : Lots for “Energy using Products directive”, previous name of “Energy related Products directive” [reference : http://ec.europa.eu/energy/efficiency/studies/ecodesign_en.htm] where scope has been splitted per families of products, grouped in so called Lots.

[4] Directorate-General for Enterprise and Industry at the European Commission.

[5] “ESCOP”: European Seasonal Coefficient of Performance.

[6] “CLE@”: Association managing databases (issued from Promodul and Edibatec associations): [reference : http://www.promodul.fr/sites/default/files/Juin_2012-Lettre%20Information%20CLEA.pdf]

Follow us on social media accounts to stay up to date with REHVA actualities

0