Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

A key role in the design and operation of zero energy buildings is played by the systems. It is well known that in the design process, once that the energy demand of the building has been reduced up to a limit which is a compromise between energy efficiency and financial feasibility, the systems are designed to reach the net zero energy target (in what way it may be seen, e.g. site energy, source energy, emissions, costs, etc.). Due to this reason, latterly there has been a new generation of systems especially designed for highly efficient buildings, Passivhaus and ZEBs able to integrate different energy sources to cover with the maximum efficiency the building energy demand.

There are basically three aspects that characterize a system for a ZEB. The first one is the need of producing on-site at least some of the energy that is consumed. A second aspect, which is characteristic of a ZEB in general, is the production from renewable sources that must supply a great portion of the energy requirement. This implies the use of systems that exploit renewable sources, with thermal or electric storages and able to cope with the variation of the driving forces. The third characteristic is the increase in the energy efficiency by using heat recovery, new technologies and the principle of hybrid system. It is known in fact, that the combination of two or more energy conversion devices and/or two or more energy sources for the same device, when integrated, overcomes the limitations that may be inherent in either source or device [1].

The energy uses of a ZEB can be summarized into:

· heating energy for high-temperature space heating, at a temperature between 55°C and 80°C;

· heating energy for low-temperature space heating, at a temperature between 35°C and 50°C (radiant heating);

· heating energy for DHW production, at a temperature between 40°C and 65°C;

· cooling energy for space cooling, at a temperature between 7°C and 19°C;

· cooling energy for air dehumidification, at a temperature below 12°C

The aspects that characterize the energy demand of a (nearly) ZEB are the followings:

· the energy demand for space heating is dramatically reduced (values can be around 15 kWh/m²a) in comparison with buildings that are in compliance with the legislative requirements; also the heating load for space heating is low, especially in zero energy homes (single family houses);

· the heating load for the DHW production is greater (double or more) than the space heating load, concentrated in time but constant throughout the year;

· there is the necessity of recovering the ventilation heat losses in order to guarantee the high performances of the whole building design, which implies the adoption of a mechanical ventilation system.

A first consequence of these assumptions is that a system for a (nearly) ZEB should integrate the ventilation and/or the DHW production into the traditional heating systems. In some cases, also the space cooling is required and provided by a packaged system.

Then, due to the small capacities, maintenance and operation simplifications, integrated solutions are preferred.

In the following paragraphs, a classification of some of the various new types of systems that were recently developed is presented and some of these systems are outlined. A detailed review can be found on [2]. Most of these systems are suitable to single family houses in north and central Europe climates; on the other hand, this is quite understandable since the design ZEBs has started from single family houses.

Figure 1. Classification of some systems for ZEBs as a function of energy uses (columns) and energy sources (rows).

These systems provide the mechanical ventilation together with space heating, domestic hot water production and – in some cases – space cooling. One of the first example of such system has been the compact packaged HVAC system of the Passivhaus design, that is based on a air-to-air heat pump of small capacity integrated with the ventilation heat recovery and supply fan, and the domestic hot water production with a suitable water storage [3].

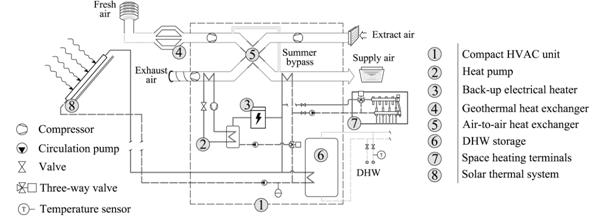

Figure 2. An example of integrated system for ventilation, DHW production and hydronic space heating (doc Zehnder)

This system is typical of the first Passivhaus and has the characteristic of using the air loop of the ventilation system to cover the remaining heat load of the spaces, which in some cases may be a limitation. More recently, in fact, systems that are similar in its general concept to the first one but that can provide also a hydronic heating (hot water at moderate temperature for radiant space heating) were manufactured. The heating capacity of the air side is around 2 kW while the heating capacity of the hydronic circuit is around or below 10 kW.

Figure 3.Schematic of an integrated system for ventilation, DHW production and hydronic space heating.

If not integrated with the DHW and space heating, centralized mechanical ventilation units must be used. These can have a supplementary electric heating for air heating, can be equipped with a static or a rotary heat exchanger and, for cooling purposes, can have a water coil installed on the primary air duct. A further configuration of these centralized units is the one equipped with reversible heat pumps working between the exhaust air and the supply air. Such systems cover not only the ventilation heating load but also, to a certain amount, the space heating load. In mid-season they work in free cooling mode.

Many new types of small size CHP for residential applications were recently developed, especially by manufacturers of boilers, and a valid alternative to traditional internal combustion engines CHP that are available on medium sizes, are the external combustion Stirling engines. This is because they have small capacities (their typical size is 1 kW of electricity – with an electric efficiency of 15% – 6 kW of heat – with a thermal efficiency of 80% – and a 6–20 kW of additional heating capacity of the gas burner), they run quietly and can be installed close to living spaces, have less emissions and can possibly make use of thermal wastes. As can be seen in Figure 4, they appear as standard households’ equipment or boilers. However the use of a CHP, even though of a small size, into a ZEB should be always carefully evaluated because the feasibility of such systems strictly depends on the running hours, on the feed-in tariff for the electricity produced and exported outside the ZEB, and on the sizing.

Figure 4.An example of a Stirling Engine CHP in a residential building (doc Baxi).

Storing energy in the form of sensible heat currently appears the most viable solution for bridging the gap between energy consumption and energy generation from various sources. With a view of optimising the exploitation of different energy sources (solar, biomass, etc.) and providing hot water at different thermal levels, multi-source multi-use water heat storages were designed and consist of different source side circuits fed by the energy source, different hydronic use side circuits (high temperature heating, low temperature heating, DHW production) and a controller. Lower coils receive heat from solar thermal, heat pumps or heat recovery from chillers condensers; intermediate coils receive heat from biomass boilers; upper coils produce DHW. Depending on the circuit, source sides and use sides can be connected hydraulically or by means of a heat exchanger. These storages rely on the thermal stratification of the water volume in order to improve the storage efficiency.

In many cases, the heat pump is the preferred choice for a ZEB. Without entering into the various types of heat pumps that can be adopted (air-to-air, water-to-water, ground source, but also condensing boiler-heat pumps, gas absorption and gas engine), and into the calculations and feasibility studies necessary for each case, the main advantages of heat pumps are the possibility to be used for space heating and cooling, the possibility of producing DHW from heat recovery, the integration with solar thermal system and the good performance at part loads. A monographic number of REHVA Journal (5/2014) was recently devoted on heat pumps for ZEB. It is interesting to note here that the main problem to be faced when installing a heat pump for space heating into a ZEB is the production of the DHW.

Due to the many peculiarities of the DHW production within a ZEB context, such as the high thermal levels, the high design heating load (e.g. 18 kW for 10 l/min with a delta temperature 15°C - 40°C, the problem related to the proliferation of legionella and last but not least the integration with renewable sources, if electric heat pumps are used, the instantaneous production is not feasible and a storage volume is necessary to level the loads. The storage volume also allows adequate temperatures for both use and source (heat pumps) sides. Basically, three plant schemes can be designed:

· a DWH storage with an internal coil (water heater): the storage volume is designed on the DHW requirement, the coil should be appropriately sized and the problem of legionella should be addressed;

· a DWH storage with an external heat exchanger: the storage volume is designed on the DHW requirement, the external heat exchanger allows higher efficiency while there are two pumps and still the problems of legionella;

· a water storage and an instantaneous heat exchanger for the DHW production: in this case the storage volume is larger, there are always two pumps, but no risk of legionella proliferation.

Systems

for ZEBs are usually integrated. The optimisation of their potential benefits requires

a whole building approach, implemented since the design concept stage until the

final design. To do this, appropriate manufacturer

data should be made available in order to perform detailed calculations of the energy

performance of the system. Currently, only synthetic data are usually available

from manufacturers (e.g., design efficiencies, mean seasonal efficiencies

calculated at reference conditions, etc.). This seems the greatest challenge facing

up multi-energy system in the near future. Their spreading on the market will depend

on the capacity to minimise the mismatch between expected (design) and real (monitored)

energy performances.

[1] J. Manwell, Hybrid Systems, Encyclopaedia of Energy, Elsevier

[2] E. Fabrizio, F. Seguro, M. Filippi, Integrated systems for HVAC and DHW production for Zero Energy Buildings, Renewable and Sustainable Energy Reviews 40 (2014) 515-541.

[3] W. Feist, J. Schnieders, V. Dorer, A. Haas, Re-inventing air heating: convenient and comfortable within the frame of the Passive House concept, Energy and Buildings 37 (2005) 1186-1203.

Follow us on social media accounts to stay up to date with REHVA actualities

0