Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

Maria KolokotroniProfessor,Institute of Energy FuturesBrunel University London, UKmaria.kolokotroni@brunel.ac.uk | Thiago SantosPhD studentInstitute of Energy FuturesBrunel University London, UKthiago.santos@brunel.ac.uk | Nick HopperTechnical DirectorMonodraught Ltd, UKnick.hopper@monodraught.com |

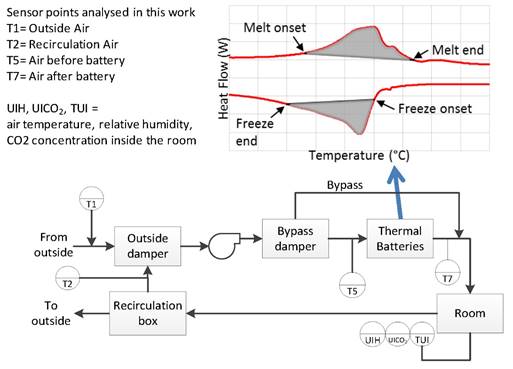

Figure 1. Schematic of Cool-Phase system

with a graphical explanation of the PCM thermal battery principle of operation.

Thermal comfort evaluation is usually based

on current guidance on avoiding overheating in buildings. In the UK, current

guidance for schools is provided by the Education Funding Agency [1]; it

includes guidelines on ventilation, thermal comfort and indoor air quality,

including the Services Output Specification [2], the Baseline Design

Environmental Services and Ventilation Strategy [3] and the Building Bulletin

101 [4]. These documents are aligned with CIBSE's guidance on prevention of

summertime overheating [5,6 ,7 ,8] which refer to calculations according to European Standard BS EN 15251 and UK

Building Regulations Parts L (Conservation of Fuel and Power) and F

(Ventilation) [9].

Until recently overheating criteria for

schools were based on fixed air temperature (28°C which can be exceeded for 120 hrs

and 32°C not to be exceeded) outside the heating season and during the occupied

period from 1st May to 30th September.

Currently, the adaptive thermal comfort

approach is used which follows the methodology and recommendations of European

Standard EN 15251 to determine whether a building is overheated, or in the case

of an existing building whether it can be classed as overheating. The new

criteria are based on a variable (adaptive) temperature threshold that is

generated from the outside running-mean dry-bulb temperature. There are three

criteria, two of which must be met for compliance, as follows [3]:

(a) Hours of Exceedence: The number of hours operative temperature

exceeds the maximum acceptable operative temperature (θmax) by 1K, must

not exceed 3% of the total occupied hours or 40 hours, during the five summer

months.

(b) Weighted Exceedance: The sum of the weighted exceedance for each

degree K above θmax (1K, 2K and 3K) is ≤ 10.0.

(c) Threshold/Upper Limit Temperature (θupp): The

measured/predicted operative temperature should not exceed the θmax by 4K

or more at any time.

The case-study analysed in this paper was

built to comply with the older requirements so operational data are analysed

following both approaches.

In terms of IAQ based on CO2

concentration, until recently the guidance was that when measured at seated

head height, during the continuous period between the start and finish of

teaching on any day, the average concentration of carbon dioxide should not

exceed 1,500 parts per million (ppm). This criterion is changed to the

following criteria [3]:

(a) Ventilation should be provided to limit the concentration of

carbon dioxide measured at seated head height in all teaching and learning

spaces.

(b) Where mechanical ventilation is used or when hybrid systems are

operating in mechanical mode, i.e. the driving force is provided by a fan,

sufficient fresh air should be provided to achieve a daily average

concentration of carbon dioxide during the occupied period of less than 1,000 ppm

and so that the maximum concentration does not exceed 1,500ppm for more than 20

consecutive minutes each day.

The case-study is a seminar room at a university

campus in West England. Cool-Phase® systems have been installed in

other spaces of the university but the seminar room was chosen because of its

use (computer laboratory) with higher internal heat gains than other spaces.

The room has a floor area of 117 m² and includes 26 desk top computers,

peak occupancy of 26 students, and artificial lighting comprising of 24

luminaires each equipped with one 48 W lamp. The total internal heat gain

in the room is 60 W/m². The room has one external wall facing west with

U-value of 0.56 W/m² K while 23 % is glazing (U-value 1.82 W/m² K)

with internal blinds. Ventilation and cooling is provided via a 8 kW

Cool-Phase® unit. Heating is provided through perimeter hot water

radiators and windows are operable. Climate is temperate maritime with 2,684 Heating

Degree Days and 196 Cooling Degree Days; 20 year average, base 15.5°C, south

west England [10].

A Cool-Phase® system by

Monodraught Ltd was installed in May 2013 to provide ventilation for indoor air

quality and cool the air for thermal comfort. The Cool-Phase® system

uses the concept of a thermal battery consisting of Phase Change Material (PCM)

plates within the ventilation path to capture and store heat. Therefore, the

thermal batteries use the latent heat property of materials to store energy,

which is charged and discharged by passing air through a heat exchanger. A

diagram of the system is shown in Figure

1 where the principle of the PCM thermal battery

function is shown. The system is concealed in the false ceiling and its

appearance to the user is that of a conventional ventilation system with two

air supply terminals and one air extract terminal. Air is drawn from outside or

the room using a variable speed fan. During operational hours and depending on internal

air quality (monitored through CO2 sensors) the air is

mixed with recirculated air from the room to conserve energy. The air is then

directed through the PCM thermal battery to be cooled if necessary (determined

by air temperature sensors and control rules) or by-passes it if cooling is not

needed. Outside operational hours, ambient air is used to recharge the PCM

thermal battery the duration of which is determined by air temperature sensors

and control rules according to the season.

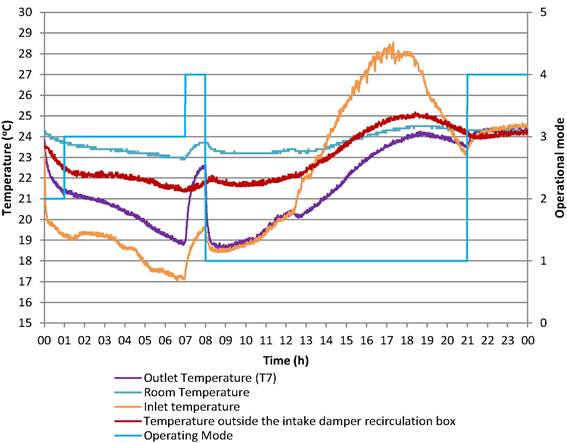

Figure 2. System operation over a summer

day in 2013.

Figure 2 shows how the system works based on monitored data during one day

in August 2013. The system starts with a charging-purge mode between midnight

and 1:00 and continues with charging mode from 1:00 to 7:00 am. Inlet and

outlet temperatures through the PCM thermal battery are decreasing with a

temperature difference between them indicating the battery is charging. The

system is off between 7:00 and 8:00 am when the cooling mode is initiated

and continues until 21:00. In the morning (8:00-~13:00) the temperature outside

the intake damper is lower than the set-point for summer (22°C) so the PCM

thermal battery is by-passed. At around 13:00, set-point temperature is

exceeded and the inlet air is directed to the PCM thermal battery through

recirculation. Inlet air is cooled to below room temperature until shortly

before 21:00 when the system is off until midnight. Maximum temperature in the

room is 24.5°C below max external temperature.

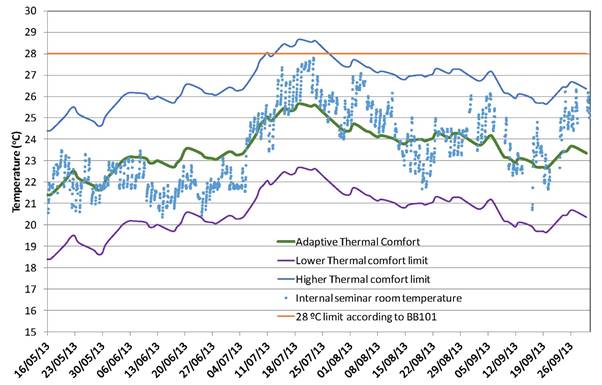

Figure 3. Thermal comfort performance over

the summer months.

Figure 3 shows temperatures in the case-study room during operational hours

in the summer of 2013 (May – September). According to adaptive thermal comfort

criteria, it can be observed that the system has achieved internal temperatures

within the upper and lower limits and therefore complies with all conditions. Also,

air temperatures do not exceed 28 or 32°C and daily average inside/outside

temperature difference is less than 5°C and therefore achieves comfort

according to static thermal comfort criteria.

An analysis of monitored room CO2 concentration was carried out for the whole year that data

are available. Table 1 presents the results. Daily average concentration during the

occupied period is always less than 1.000 ppm and the 1.500 ppm limit

was not exceeded with the exception of one occasion for 22 min when

occupancy was higher than designed and there was a conflict between IAQ and

thermal comfort.

Table 1. CO2

concentration (ppm): daily average and exceeding 1500 ppm for more than 20

consecutive minutes.

Month | Average | >1500ppm | Month | Average | >1500ppm |

May | 502 | 0 | November | 741 | 0 |

June | 423 | 0 | December | 566 | Once* |

July | 413 | 0 | January | 601 | 0 |

August | 416 | 0 | February | 719 | 0 |

September | 500 | 0 | March | 695 | 0 |

October | 595 | 0 | April | 579 | 0 |

*CO2 concentration

exceeded 1500 ppm for 22 min on mid-morning on 6 Dec 2013 when

occupancy in the room was more than its maximum and external air temperature at

~7°C. The control system restricted outside air to the room to less than

maximum capacity to avoid thermal comfort issues.

The fan energy used by the system for the

year was calculated to be 90 kWh. This equates to 0.77 kWh/m²/annum.

Annual electricity energy use intensity for secondary schools has a median of

51 kWh/m² [8]. This increases by 5 kWh/m² when moving from ‘heating

and natural ventilation’ to ‘heating and mechanical ventilation’ buildings. CIBSE

TM57 [8] presents good case-studies with cooling energy intensity of 12.5 kWh

and 3.5 kWh/m².

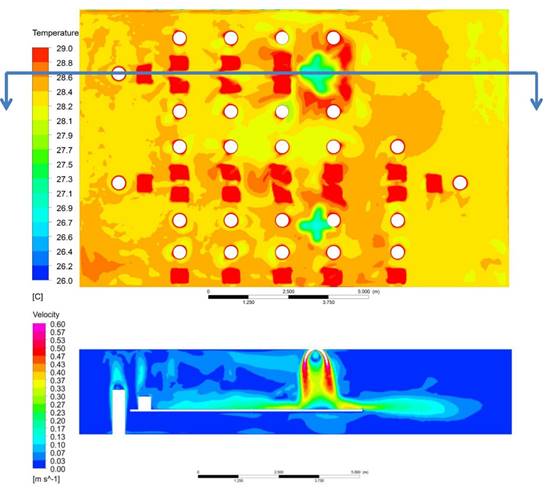

Figure 4. Air temperature and velocity in

two sections of the seminar room during the hour with highest internal

temperature (see Figure 3) and full occupancy and internal gains.

In the previous section average

environmental conditions in the room were reported. However, the distribution

is also important to examine whether there are areas within the room that

deviate from thermal comfort requirements. This was investigated using a CDF

model of the room. A 3D model of the room was constructed with summer boundary conditions;

the hour in July with the highest internal temperature was selected as the worst

case scenario and a steady state simulation was performed with full occupancy

and internal heat gains. Figure 4 shows the air temperature at 1.2 m height (student sitting

plane) and velocity fields at the plane of one air inlet. It can be observed

that air temperature is uniform across the room and there are no areas with

much higher air temperature which will cause discomfort. The air velocity

contours indicate that at occupancy level underneath the air inlet velocity is

in the range of 0.1–0.2 m/s with some small areas reaching 0.37 m/s Air

velocity is lower in the rest of the room. Changing the direction of inlet

louvres would reduce air velocities if this is required although higher

velocities might aid thermal comfort.

Analysis of one-year operational

environmental data for a seminar room equipped with a Cool-Phase®

system to provide cooling indicate that the system performs well throughout the

year in terms of IAQ and thermal comfort for an IT intensive seminar room. Further

analysis of a second year of operational data plus additional monitoring to

study the distribution of environmental conditions in the room and feedback by

users is under progress and will be reported in a case-study being developed

for EBC Annex 62.

[1] https://www.gov.uk/government/publications/acoustics-lighting-and-ventilation-in-schools/acoustics-lighting-and-ventilation-in-schools,

assessed 07/08/2015.

[2] EFA,

Services Output Specification, June 2013;

https://www.gov.uk/government/publications/psbp-facilities-and-services-output-specifications;

assessed 07/08/2015.

[3] EFA,

Baseline Designs for Schools, 'Environmental Services Strategy' and

'Ventilation Strategy', March 2014,

https://www.gov.uk/government/publications/psbp-baseline-designs; assessed

07/08/2015.

[4] Building

Bulletin 101, Ventilation of School Buildings, July 2006.

https://www.gov.uk/government/publications/building-bulletin-101-ventilation-for-school-buildings;

assessed 07/08/2015.

[5] CIBSE

Guide A, Environmental Design, Chapter 1 Environmental Criteria for Design,

Eighth edition March 2015.

[6] CIBSE

TM52. The limits of thermal comfort: avoiding overheating in European

buildings, July 2013.

[7] CIBSE

KS16. How to manage overheating in buildings: A practical guide to improving

summertime comfort in buildings, July 2010.

[8] CIBSE,

TM57, Integrated School Design, April 2015.

[9] http://www.planningportal.gov.uk/buildingregulations/approveddocuments/;

assessed 07/08/2015.

[10] http://www.vesma.com/;

assessed 10/08/2015.

Follow us on social media accounts to stay up to date with REHVA actualities

0