Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

René CyssauFormer chief engineer in COSTICAssociated member of ACR French BAC Trade

UnionCEN TC247/TC371 Technical Expert for BACr.cyssau@sfr.fr |

Standards EN 12098

(parts 1, 3, 5) prepared under CEN/TC247/WG6 committee describe ability of devices

and integrated functions to control heating systems. These standardised

functions are leading and necessary. They are completed by added functions for specific

applications and performance improvements.

Associated draft

Technical Reports CEN/TR 12098 (parts 6, 7, 8) summarise some recommendations

for how to design, how to use these functions for energy efficiency of heating

systems. Energy impact of these control functions are detailed in EN 15232-1.

Many of these EN and CEN/TR (Technical Reports) are

formally drafts until mid of 2016 and will go out for Formal Vote by October

2016. Publication by the national standards bodies of CEN is expected by the

beginning of 2017. They were prepared in the frame of the standardisation

mandate M480 with the terms set in the recast of the EPBD (2010/31/EU). |

First,

application of control functions implies that the building is properly divided

into elementary spaces and zones according to various conditions of use.

For this, EN ISO 52000-1,

“Energy performance of buildings – Overarching EPB assessment – Part 1:

General framework and procedures” gives pertinent indications for zoning in clause

10. Although this clause is formally applicable to calculated energy

performance, it may be applied to design and realisation of separated zones. Reality

of zoning is a necessity for control, limited areas up to 1 000 m² is

recommended.

Controllers

distributed on zones of buildings shall be related to hierarchical level in the

zoning and organised in a coordinated system. Energy performance of heating

systems involves suited BAC functions.

Properly

heating system zoning is a prime importance for application of this simplest

but most effective function.

Note that energy use is approximately proportional

to the ambient temperature related to outside temperature. Any stopping or

reducing heating lowering this temperature brings savings. |

For this,

12098-5 standard describes characteristics of scheduling clocks for

the operation requirements.

Five

categories cover all technologies on the market, from mechanical clocks mains

frequency synchronised to networked clocks put in sync with a high precision master

clock like the European emitter in Mainflingen (D) giving real time, date, and

automatic summer-winter time change.

Categorized

clocks may differ by programming periods, number of switch times per day,

number of daily programs. Accuracy is given for the clock itself and for switch

time settings.

Basic

scheduling function should be completed with added functions.

For adaptation

to different user needs:

·

Derogate

or overlap scheduling for temporary demand,

·

Start

timer function for a single start-stop cycle.

For

adaptation to technical constraints:

·

Fixed

start period anticipating inertia of heating before the normal occupation time,

·

Tariff

compensation in case of variable tariff energy price, like electricity, for

start switching with respect to the tariff rising time. This function provides

cost saving.

CEN/TR 12098-8

recall that

switching on-off energy services related to actual or predictable use of rooms,

zones or buildings is the basic, simplest and more effectiveness function.

Special attentions shall be given to keep watch for update schedulers to real

conditions of use, during exploitation.

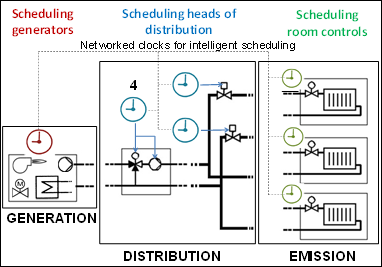

Figure 1indicates where start stop functions may be

applied to heating systems parts:

·

Generation:

switch on-off or allow-prohibit operating of generators and related

auxiliaries: pumps, valves.

·

Distribution:

switch pumps and tree ways valve controlling temperature at the head of

distribution zones. In some cases, elementary spaces and zones may be switched

by on-off seal valves.

·

Emission:

scheduling clocks are normally included in each room controller for local

adaptation of heating needs. Programming of generation and/or distribution take

priority to local programming, avoiding forgetful use or malfunctioning room

controllers (Figure 2).

Scheduling functions in heating parts and heating

zones imply a digital network linking these functions for easily coordinate

and manage. |

Figure 1.

Scheduling clocks on different parts and zones of heating systems are efficiently

synchronized and managed by the way of a digital network dedicated to HVAC

applications.

Clock

scheduling intermittences is completed with derogation possibilities for

override programmed periods. A timer function for single period may also be

proposed. These added functions started manually or automatically satisfy

unexpected needs.

The lot of

individually programmed clocks distributed in buildings imply to link

schedulers on a BAC (Building Automation and Control) system by the way of a

digital network.

A BAC is - at least - a super, multi ways scheduling

clock to put rhythm of energy use in buildings. |

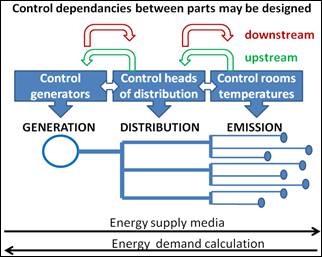

Piloting

heating systems necessitate two main functions: Outside Temperature Control (OTC)

and improved scheduling, the Start-Stop Optimiser (SSO). For an efficient

heating control these two functions are inseparable and integrated on a heating

pilot controlling many parts of these systems (Figure 2).

The EN 12098-1

describes operating requirements of OTC and SSO functions and tolerances

limits for their ability. This standard concerns either standalone devices or integrated

functions in BAC systems.

OTC – Outside

temperature controlling flow temperature may be completed by these useful functions:

·

Auto

tuning heating curve parameters;

·

Compensation

by emitters energy demand transmission;

·

Other

meteorological variables and forecast.

OSS – Optimum

start-stop function may be completed by these switchings:

·

Summer-winter

switch related

to calculated mean forecast outside temperature.

CEN/TR 12098-8

points out

that the role of heating outside temperature control acting generation and/or

distribution parts remains alone for the room temperature control in some

cases:

·

Heated

spaces don’t permit to measure a representative temperature for individual

(closed loop) control (e.g.: entrance, corridor, reception hall, exhibition

hall, atrium...),

·

Users

are not encouraged to adapt set point of their room temperature controller,

·

Emitters

are equipped with inefficient or damaged individual emitters thermostats.

And even if

each room is equipped with emitter’s controller:

·

Limit

the higher room temperature able to be reached, even in case of maladjusted settings,

·

Adapt

the water temperature to the actual heating load, allowing to avoid hanging of

the closed loop room controls, and permitting the room control accuracy.

This rule applies specially to mechanical and

electronic thermostatic radiator valves, water temperature must be adapted to

the heating charge, i.e. outside temperature. |

Energy

impact of these functions: OTC, intermittent control and pump control may be

fund on many parts of EN 15232-1.

Thermal

calculations impact of these functions may also be found in EN 15316

series:

·

Improve

efficiency of generators, reduce losses: EN 15316-4-1 gives algorithms for

calculates efficiency related to the mean temperature,

·

Reduce

heat losses of thermal storages, pipes, auxiliaries, and other equipment (e.g.

valves): EN 15316-3 gives algorithms for calculate heat losses for these

periods,

·

Reduce

pumps consumption during intermittent periods and summer-winter switch: see EN 15316-3.

Energy

efficiency of electrical heating requires central functionalities for improve

control and scheduling of terminals and their thermostats.

The EN 12098-8

describe Outside Temperature Control (OTC) and improved scheduling the

Start-Stop Optimiser (SSO) for electrical heating control systems.

Although these

functions are similar to principles applied to water heating, technical solutions

and constraints specific to this electrical heating necessitate this separated standard.

Optimum

start function may take account of the variable price of energy, for that the

switch time for rise to normal room temperature should be anticipated with

respect to the tariff rising time.

CEN/TR 12098-7

point out the

roles of outside temperature control limiting electrical energy available at

the emitter. This CEN/TR indicates also energy impact of central control and

intermittent control on distribution and emission electrical heating, as it can

be found in EN 15232-1.

Content of

this EN standard and accompanying CEN/TR presents many similarities with water

heating documents EN 12098-1 and CEN/TR 12098-6. It’s an advantage

for technicians to find similar concepts for starting up and commissioning

heating controls, whatever energy source is used.

For energy

calculation following EN ISO 52000-1, emitter’s energy demand begins on

an upstream calculation process, distribution and production delivery follows.

Physical is

opposite: energy is supplied from generators to emitters through distribution, control

falls water temperature or flow along the chain.

Figure 2.

Energy demand and supply model for heating plant. The control system may follow

an upstream or downstream model. The difference is the freedom allowed to users

acting set-points in view to take account user behaviour encouraged or not.

A control

system allows choosing subordinations between parts (Figure 2).

Two directions are feasible:

·

The

upstream control process: demand of room temperature controllers govern

distribution, storage and generation water temperature. This satisfies a

comfort point of view: delivered energy must satisfy demand.

·

The

control system may behave on a downstream process: generation and distribution

control water temperature available for each elementary spaces or rooms.

Delivered energy respond to a predicted demand, no more. This satisfies an energy

point of view. This control is based on models.

OTC and OSS

are basic functions for this downstream principle (but recommended in any

cases). Through this way, control may receive many refinements like TABS

control (Thermally Active Building Systems).

Note that these subordinations may confer a

“character” to a control system: “obedient” or “authority” over users. |

An

“obedient” system, i.e. allowing some settings access, convene to encouraged

users to pay attention to energy conservation. In other cases, an “authority”,

i.e. closely pre-set system convene to not encouraged users.

Conception of

control systems based on data networks and intelligent controls allow such

possibilities, introducing expected behaviour of contributors.

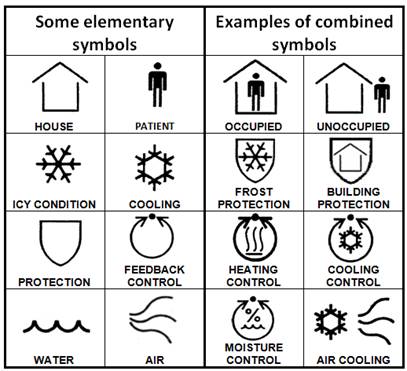

For that,

man-machine-interface is an important topic for any contributor. In this way, CEN/TC247

standards refer to graphical symbols for users in CEN/TS 15810 (Technical

Specification, Figure 3).

Figure 3.

Some symbols fund on CEN/TS 15810 “graphical symbols for use on integrated

building automation equipment” designed from elementary symbols.

Follow us on social media accounts to stay up to date with REHVA actualities

0