Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

Sylvain CourteyHead of Ventilation DepartmentEuroventCertita Certification |

Back in

2014 EuroventCertita

Certification started a new certification programme for Residential Air

Handling Units. This programme is based on state-of-art European testing

standard EN 13141-7 and in-line with the European regulations 1253/2014 and

1254/2014 related respectively to Ecodesign and

Energy Labelling.

This

certification programme concerns only balanced supply and exhaust ventilation

units including a heat recovery systems (plate, rotary or heat-pumps). These

systems are becoming more and more popular in Europe and not only in

Scandinavia due to the stricter requirements regarding energy efficiency in

residential buildings. Dwellings are becoming more and more isolated and tight

in order to save energy for heating. Infiltration through the building envelope

are therefore minimized and mechanical ventilation is therefore necessary to

renew the air inside houses.

A good

ventilation system should gather the following characteristics:

·

insure

the renewal of the air according to the needs related to indoor sources of

pollutants (occupancy and building materials)

·

consume

a small amount of energy directly (through the consumption of the fans) or

indirectly by discharging warm air from inside to outside while providing cold

air from outside to inside

·

produce

a sufficiently low sound power level so that occupants do not switch off the

unit due to noise pollution

·

be

airtight in order to not recirculate indoor pollutants back in the building

·

provide

clean air inside even when outdoor air is polluted

The scope

of the Eurovent certification programme includes all

balanced supply and exhaust ventilation units with heat recovery systems

(plate, rotary or heat-pump) up to 1 000 m3/h

nominal airflow.

The

following characteristics are certified:

·

Leakage

class

·

Aeraulic

performances (Airflow/pressure curves, Maximum airflow [m3/h])

·

Electrical

consumption [W]

·

Specific

Power Input SPI [W/(m3/h)]

·

Temperature

efficiency / COP

·

Performances

at cold climate conditions

·

SEC

(Specific Energy Consumption) [kWh/(m².year)]

·

A-weighted

global sound power levels [dB(A)]

All

performances are checked by tests done according to the European standard EN

13141-7:2011 by independent testing laboratories accredited according to ISO

17025.

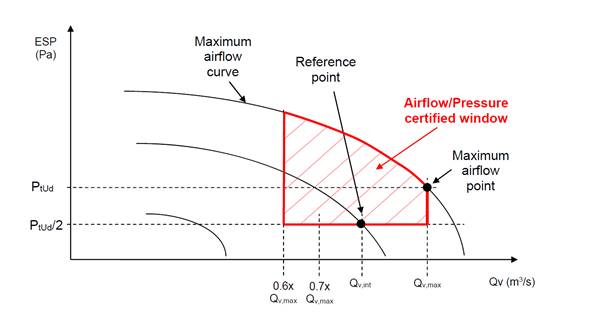

Aeraulic

performances are verified for a certified window as described in Figure 1

below.

Figure 1.

Certified window of airflow/pressure curves according to RS 15/C/001-2015.

Leakage classes are defined based on both

internal and external leakages (see Table 1for an example).

Table 1.

Leakage classification for the pressure method according to EN 13141-7:2011.

Class | Pressurization test Internal leakage External leakage (at 100 pa) (at 250 pa) | ||

A1 | ≤2% | and | ≤2% |

A2 | ≤5% | and | ≤5% |

A3 | ≤10% | and | ≤10% |

Not

classified | >10% | and | >10% |

Heat

recovery systems are evaluated according to the conditions given in Table 2

below.

Table 2. Testing

conditions for heat-recovery efficiency according to EN 13141-7.

Application Mode | Standard test | Cold Climate test | ||

Point number | 1 | 2 | 3 | 4 |

Heat

Exchanger category | I and II (mandatory) | I (mandatory) and II

(optional) | I and II (optional) | I and II (optional) |

Extract

air | ||||

Temperature | 20°C | 20°C | 20°C | 20°C |

Wet

bulb | 12°C | 15°C | 12°C | 10°C |

Supply

air | ||||

Temperature | 7°C | 2°C | -7°C | -15°C |

Wet

bulb | - | 1°C | -8°C | - |

This

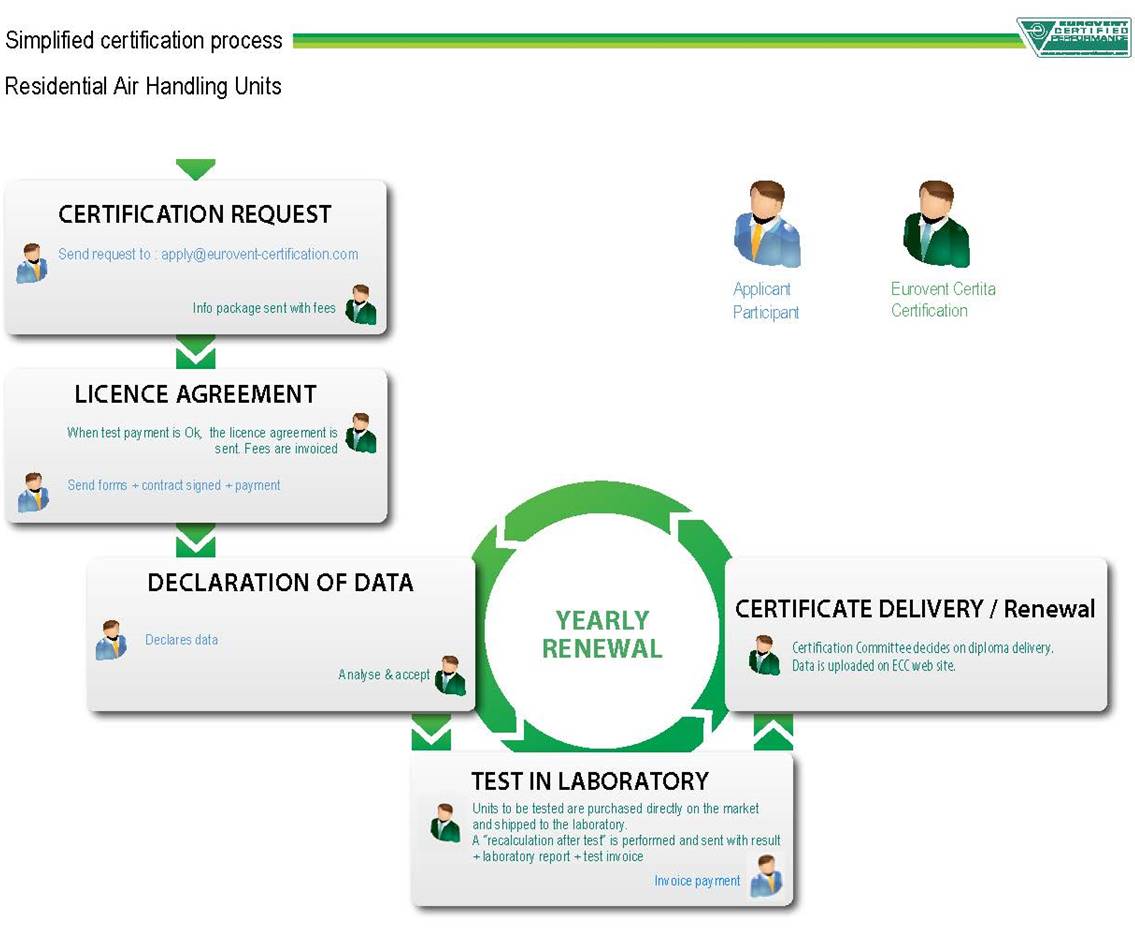

certification programme is based on random selection of units purchased

directly on the market thus allowing to assess the real performances of the

units provided to end users.

Figure 2.

Simplified certification process for the RAHU Eurovent

programme.

Even if

this certification programme was introduced in the course of 2014, it already

included at this time the characteristics of the European regulations 1253/2014

and 1254/14 which were applied on the European market on the 1st of January 2016. These regulation introduced Ecodesign regulations for residential ventilation systems

as well as requirements regarding the way performances shall be displayed, in

particular regarding energy efficiency with a dedicated energy efficiency

label.

This energy

efficiency classification is based on the Specific Energy Consumption (SEC)

which accounts for both the direct energy consumption of the fans but also the

indirect energy consumption related to the heat recovery efficiency.

The Eurovent certification programme is therefore a good mean

to verify the compliance of ventilation units according to these regulations.

Even though

energy efficiency is a key element when looking at residential ventilation

units, the first performance parameter for such unit is its ability to maintain

a good indoor air quality in the building.

As seen

before this is related to the ability of the unit to:

·

remove

indoor pollutants from occupant activities (CO2,

humidity) and from building materials (COVs)

·

prevent

outdoor pollutants to enter into the building (particulate matter)

·

not

re-introduce indoor pollutants in the building

All of

these should be done at the lowest cost possible.

In order to

characterize this essential characteristic of these products ECC decided to

introduce a new metric allowing to take into account all these parameters: the

Clean Air Efficiency (CAE):

| Eq.

1 |

In order to

define what “clean air” is, only the main pollutants are taken into account:

·

Indoor

pollutants:

−

CO2

−

Humidity

·

Outdoor

pollutants:

−

Particulate

matter

Other

pollutants can also be found such as COVs coming from building materials

indoors (formaldehyde) or from outdoors (benzene), allergens from indoors

(pets) or outdoors (pollen), micro-organisms … It was deliberately decided to

focus on the main pollutants in order to achieve a good balance between

relevance and simplicity.

As a result

the amount of clean air delivered to the building is assumed to be the minimum

between the clean air delivered related to indoor pollutants (CO2 and humidity) and the clean air delivered related to

outdoor pollutants:

| Eq.

2 |

The amount

of clean air concerning CO2 and humidity is simply

the amount of air removed from the building by ventilation minus the amount of

air recirculating from the extract air side to the supply air side due to internal

leakages within the ventilation unit:

| Eq.

3 |

With:

EATR: the Exhaust Air Transfer Ratio [-] which accounts for internal

leakages from the extract side to the supply side

qv,int: the airflow

rate at the referent point according to EN 13141-7 [m3/h]

The amount

of clean air concerning particulate matter is considered to be related to the

efficiency of the air filters towards PM1

particles. PM1 particles are the most harmful

category of particles which are from various origins (dust, combustion particles,

bacteria, viruses). These particles are able to enter into the deepest part of

our lungs until the alveoli. Both supply and exhaust air filtration

efficiencies have to be considered as indoor particulate matters may be

re-introduced indoors through internal leakages:

| Eq.

4 |

With:

ePM1,supply and ePM1,exhaust: efficiencies against PM1 particles of

the supply air and exhaust air filters respectively.

In order to define the total energy used by the unit we propose to

introduce the Total Energy Consumption TEC in kWh/m²/year which is analogous to

the SEC but which is always positive:

| Eq.

5 |

| Eq.

6 |

With:

![]()

![]()

![]() : constant value

[kWh/m²/year]

: constant value

[kWh/m²/year]

Finally:

| Eq.

7 |

With:

qnet: net ventilation rate demand per m2 heated floor area [m3/h.m2]

In order to

have basic figures in mind the Table 3 below summarizes typical CAE values for poor,

average and good ventilation units.

Table 3.

Typical CAE values.

Poor | Average | Good | |

Supply air filter | G3 | M5 | F7 |

Exhaust air

filter | G3 | M5 | F7 |

Leakage class (EATR) | A3 (10%) | A2 (5%) | A1 (2%) |

SPI [W/(m³/h] | 0.50 | 0.35 | 0.25 |

HRS efficiency | 55% | 80% | 90% |

Ventilation

control (CTRL) | Clock control (CTRL=0.95) | Central demand control (CTRL=0.85) | Local demand control (CTRL=0.65) |

Motor drive (x) | 2-speed (x=1.2) | Multi-speed (x=1.5) | Variable speed (x=2= |

CAE

[(m³/h)/(MWh/year)] | 5 | 20 | 146 |

Recent

European regulations have already shaped the market towards better energy

efficient products. However, it has to be kept in mind that the primary role of

ventilation units is to bring clean air to building occupants. In order to

highlight this a new, simple and meaningful metric was developed within the Eurovent Certification programme for Residential Air

Handling Units: the Clean Air Efficiency (CAE). This performance will be made

available for all Eurovent certified units by the 1st of March 2017. It will allow end-users to compare

easily products between each other’s regarding their essential characteristic

that is its ability to provide good indoor air quality in buildings.

OM-16,

Operational Manual for the Certification of Residential Air Handling Units,

November 2015, wwww.eurovent-certification.com

RS

15/C/001-2015, Rating Standard for the Certification of Residential Air

Handling Units, November 2015, wwww.eurovent-certification.com

EN

13141-7 :2011, Performance testing of components/products for residential

ventilation. Part 7: Performance testing of a mechanical supply and exhaust

ventilation units (including heat recovery) for mechanical ventilation systems

intended for single family dwellings.

COMMISSION

REGULATION (EU) No 1253/2014 of 7 July 2014 implementing Directive 2009/125/EC

of the European Parliament and of the Council with regard to ecodesign requirements for ventilation units, http://eur-lex.europa.eu

COMMISSION

DELEGATED REGULATION (EU) No 1254/2014 of 11 July 2014 supplementing Directive

2010/30/EU of the European Parliament and of the Council with regard to energy

labelling of residential ventilation units, http://eur-lex.europa.eu

Follow us on social media accounts to stay up to date with REHVA actualities

0