Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

Burhan YorukIstanbul Technical University, | Ahmet ArisoyIstanbul Technical University, |

When a

cooling based climate is considered, evaporative cooling of outer walls during summer can be a very valuable

tool for reducing cooling energy from outer skin of the buildings. There are some

solutions in the literature based on this principle. However, applying such an

evaporative layer on the inner surfaces of the outer walls is a novel approach.

At this stage only the idea has been evaluated.

A case

study, in which the target is reducing cooling energy (heat gains) from outer

walls for energy conservation has been conducted. Cooling inner surfaces of the

outer walls reduces heat gain from the outer walls and more importantly

increases the thermal comfort indoors in summer conditions by decreasing the

wall temperatures.

Simulation

results show that this

system is more successful comparing to the thermal insulation in Mediterranean

climate. Depending on the design parameters the peak heat gain through the

outer walls can be compensated by the system without any additional insulation

layer. Even in some favourable conditions an additional cooling effect can be

achieved besides avoiding heat gains from outer walls.

The

definition of energy efficiency measures and packages are strictly related to

the climate, considering both temperature and humidity. Therefore, for hot and

dry regions, specific solutions are certainly required. In particular,

Mediterranean climate is characterized by a dominant cooling demand and varying

outdoor conditions along the day.

Behaviour

of outer walls plays an important role on heat gains and heat losses of the

building. Thermal insulation of walls is known as an important measure to

reduce static heat loss of buildings for cold and mild climates. However,

increasing thermal insulation thickness plays a reverse effect on heat gains

due to dynamically changing outdoor conditions for hot climates [1]. Instead of increasing thermal insulation

thickness, evaporative cooling of outer walls can be used reducing cooling

energy from outer skin of a building in such climates.

An

evaporative layer to be applied on the inner surfaces of outer walls has been

designed to reduce the cooling energy of buildings in Mediterranean region in

this study. This can be considered as a new approach.

This work

presents a case study. A building in Mediterranean region has been considered as

an air conditioning system that keeps indoor temperatures at the required

level. The target is reducing cooling energy (heat gains) from outer walls for

energy conservation. The proposed heat absorbing layer basically consists of

two plates with a gap between them and it is applied on the inner side of the

outer walls. Indoor air passes through this gap from bottom to top, across all

the length of the wall. Back plate is actually a moist pad and evaporation of

water from this pad creates a cooled wall surface. Cooling inner surfaces of

the outer walls reduces heat gain from the outer walls and, more importantly,

increases the thermal comfort indoors in summer conditions.

A dynamic

computer model has been developed to simulate the system. This model can consider

the effects of thermal mass of the wall too.

It is shown

that this system is successful in Mediterranean climate. Depending on the

design parameters, the heat gain through the outer walls can be compensated by

the system without any additional insulation layer. Even in some favourable

conditions an additional cooling can be achieved. This layer is also effective

during the winter conditions. In winter season, the layer is used in dry state

and it reduces the heat loses.

A standard

building in Izmir-Turkey is considered as the reference case in this study.

Izmir is selected as the representative of the Mediterranean climate. The building

is a two storey residential house with 512 m²

total floor area. Total outer wall area is 314 m² and only 211 m² of

this wall can be covered by the proposed layer. Density of 5 cm thick

concrete external walls is 1,600 kg/m³. Thermal mass is an important

parameter effecting on thermal performance of the building skin and this value

has been parametrically studied in this paper. 5 cm thick thermal

insulation is necessary, in this case, to remain within the limits of the

standard. All other external and internal heat gains/losses have not been taken

into consideration in this study.

It is

assumed that there is an ideal HVAC system which controls indoor temperatures

ideally. Cooling set point temperature is 24°C for summer period. Heating set

point temperature is 21°C during the

winter period. Total ventilation air rate is 1 013 m³/h which

corresponds to 0.66 air change per hour.

This

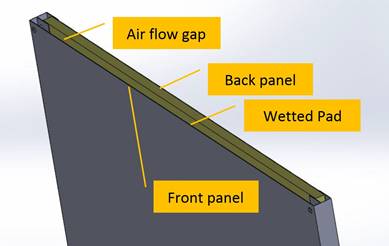

approach is based on a modular evaporative layer to be applied on the inner

surface of the outer walls. This layer is to be attached to the wall surfaces

tightly by screws and it should be leak-proof. The drawing of a module is seen

in (Figure 1). These modules can be connected to

each other and all the outer wall inner surfaces can be covered with these

elements. Frame of the module is steel and the panels of the module can be

either plastic or sheet steel. There is a porous pad attached to the back-side

panel of the module, there is a gap for air flow between this pad and the front

side panel of the module. The pad is made of synthetic fibers and it

is wetted by the water dripping nozzles at the top. Gap dimensions and air flow

rate have been defined by the help of the developed computer program. Room air

is introduced to the gap from bottom of the module and this air picks up the

evaporated water from wetted pad. Collected moist air at the top of the gap is

exhausted to the outdoor by the help of a fan. This air circulation system can

also be part of the mechanical ventilation system of the building. In this

system, no moist air is introduced in indoors.

Figure 1.

Drawing of the designed evaporative module.

Two

different cases have been studied as wetted pad in summer and dry pad in winter

to evaluate the year-round performance of the proposed layer. Hourly

temperature and humidity variations and the resultant heat gain/loss values

have been solved for these cases. Using the model results, optimized

dimensions, air flow rates and water feeding rates have been determined.

Effects of wall thermal inertia have been investigated, performance of the

proposed system have been evaluated.

The

optimized air flow gap/clearance is 0.01 m and optimized air flow velocity

is 0.8 m/s. Indoor air temperature (and the air temperature at the

entrance of the layer) is 24°C and the humidity ratio of air is 0.0093 kg/kg

for summer season. This humidity ratio corresponds to 50% relative humidity.

Indoor air temperature (and the air temperature at the entrance of the layer)

is 21°C and the humidity ratio of air is 0.0078 kg/kg for winter season.

Hourly changing outdoor temperature and solar radiations on the outer surfaces

of the wall in each direction have been considered as boundary conditions.

Hourly weather data of the typical year has been taken from International

Weather for Energy Calculations Database [2].

In Case A,

the pad is kept wet by supplying water from top. With the help of evaporation,

inside wall surface temperatures can be kept below the room temperature. In

these conditions, besides preventing heat gain from outer walls, an additional

cooling effect is seen. A heat loss occurs from indoor air. Low inner surface

temperatures also help improving comfort conditions due to radiative heat

transfer between cooled wall and the human body. Mean leaving air temperature

at the middle of the wall for the first week of July in a typical year is 25.3°C

which is very close to the room air. Meanwhile, specific humidity increases

from 9.3 g/kg to 17.6 g/kg in exhaust air. Leaving air specific

humidity corresponds to approximately 70% relative humidity value. This humid

and cool air can be used in a conventional heat recovery unit to reduce the

temperature of incoming hot ventilation air.

Heat gains

through cooling months are given in Table 1. Negative values indicate heat loss

(additional cooling) and positive values indicate heat gain. Besides preventing

heat gains from outer walls, additional cooling created by the evaporative

layer along five cooling months, is 16,294 kWh. However, without applying

this evaporative layer, total heat gain from same bare walls was 43,925 kWh.

Thermal insulation can reduce the heat gain to a certain extent in summer

months, but additional cooling effect cannot be created by only a thermal

insulation. It seems adding such a layer inside the walls, causes much better

performance than the thermal insulation for hot and dry regions and in

dynamically changing outdoor conditions.

Table 1.

Monthly heat gains of the building only from the outer walls [kWh].

EvapWall | Bare Wall | With Isolation | |

May | −4587 | 4516 | 983 |

Jun | −2838 | 9885 | 2189 |

Jul | −2512 | 11637 | 2593 |

Agu | −2827 | 10452 | 2325 |

Sep | −3530 | 7435 | 1663 |

Heat loss

should be reduced from the outer walls in winter. November, December, January

and February are four winter months. The common solution for this is applying

thick thermal insulation to the outer walls. Without any thermal insulation,

mean inner surface temperature of bare wall is 16°C in a typical January week.

In (Case B)

the pad is kept dry but the air flow continues. It is assumed that indoor

temperature is kept constant at 21°C by the heating system in winter. Inside

wall surface temperatures can be increased by the flowing warm room air in the

layer gap. These elevated inner surface temperatures reduce the heat loss and

also help improving comfort conditions. The mean temperature of air is 19.1°C

in the gap and the mean temperature difference between the room and the layer

is about 2ºC. In winter conditions, this proposed dry layer can be considered

as a heat recovery unit. Air flow rate is also the same as in the summer case

and correspond to the ventilation air rate (total 1,013 m³/h). There could

be a conventional heat recovery unit in the system, in this case, this layer

and heat recovery unit work in parallel.

Heat loss

through winter months are given in Table 2. Total heating energy for 4 winter

months is 15,779 kWh. Without applying this dry evaporative layer, total

heat loss from same bare walls is 25,413 kWh. This reduction is big enough

to consider.

Table 2.

Monthly heat losses of the building only from the outer walls [kWh].

DRY | Bare | Isolation | |

Jan | −4572 | −7352 | −1652 |

Feb | −4011 | −6465 | −1443 |

Nov | −2494 | −4020 | −854 |

Dec | −4701 | −7576 | −1672 |

Thermal

insulation is the most effective solution in winter. However, without any

thermal insulation EvapWall decreases heat losses

almost half compared to the bare wall.

Considering

both summer and winter performances of the proposed layer, annual energy need

for the building and the outer wall have been calculated. This performance

value has been compared with the bare wall and the 5 cm

thick insulation covered wall. Evaporative layer will work wet during the five

summer months and will work dry during the 4 winter months. Building energy

simulation has been carried out by using Energy-Plus software for bare wall and

the insulated wall. Temperature set points are again 21 for four winter months

and 24°C for the rest of the year with air conditioning system that operates 24

hours. Results are given in Table 3. Negative sign

for EvapWall indicates additional cooling effect. All

other figures are considered as load and there is no sign of differentiation

for heat gain or loss in the table. March, April and October can be considered

as intermediate season. Both cooling and heating are required during these

months. However, outer walls in each case more or less perform as a cooling

element and reduce total mechanical cooling load in these months.

Table 3.

Total monthly heat (energy) lost/gain only from outer walls [kWh].

| Insulated wall | Bare wall | EvapWall | |||

Month↓ | Heat loss/gain by the wall (kWh) | Total energy requirement of the system (heating or cooling) (kWh) | Heat loss/gain by the wall (kWh) | Total energy requirement of the system (heating or cooling) (kWh) | Heat loss/gain by

the wall (kWh) | Total energy requirement of the system (heating or cooling) (kWh) |

January | 1652 | 6800 | 7352 | 12500 | 4572 | 9720 |

February | 1443 | 6735 | 6465 | 11757 | 4011 | 9303 |

March | 1430 | 4196 | 6178 | 8944 | 3804 | 6570 |

April | 660 | 2700 | 3038 | 5078 | 1849 | 3889 |

May | 983 | 4919 | 4516 | 8452 | −4587 | 0 |

June | 2189 | 8011 | 9885 | 15707 | −2838 | 2984 |

July | 2593 | 8025 | 11637 | 17069 | −2512 | 2920 |

August | 2325 | 10452 | 10452 | 18579 | −2827 | 5300 |

September | 1663 | 5493 | 7435 | 11265 | −3530 | 300 |

October | 127 | 3226 | 618 | 3717 | 373 | 3472 |

November | 854 | 5803 | 4020 | 8969 | 2494 | 7443 |

December | 1672 | 6450 | 7576 | 12354 | 4701 | 9479 |

Annual | 72810 | 134391 | 61380 | |||

According to these results, applying evaporative layer is the best solution for İzmir. The 5 cm thick thermal insulation reduces annual building energy requirement from 134,391 kWh to 72,810 kWh. Saving of energy is about 61,581 kWh annually. However, in case of proposed evaporative layer, annual energy saving is higher comparing the thermal insulation. The proposed layer reduces annual building energy requirement from 134,391 kWh to 61,380 kWh and saving of energy is about 73,012 kWh annually. It seems that this proposed system is advantageous for hot and dry climates.

Thermal mass of the wall highly influences the

performance of the outer wall. When outdoor whether conditions change daily and heat loss and gain

occurs in the same day, thermal mass of the wall becomes important. Increasing

thermal mass improves the thermal performance in dynamic climate conditions.

This is especially effective during intermediate seasons. Wall thickness has

been doubled in this case study and all the calculations were repeated for the EvapWall case. Calculated heat loss values are given in Table 4. Because these values are always heat loss, the sign is negative. This

monthly negative value should be as low as possible in winter and as much as

possible in summer. In case of thick wall, heat loss decreases in winter and

cooling effect increases in summer. This means increasing thermal mass acts

positively in a year-round performance of the wall.

Table 4.

Comparison of thermal mass on wall thermal performance. Monthly heat loss of

outer walls [kWh.]

EvapWall Heavyweight heat loss | EvapWall Lightweight heat loss | |

Jan | −4572 | −5779 |

Feb | −4011 | −5050 |

Mar | −8040 | −8253 |

Apr | −6795 | −6614 |

May | −4587 | −3496 |

Jun | −2838 | −1258 |

Jul | −2512 | −734 |

Agu | −2827 | −1145 |

Sep | −3530 | −2194 |

Oct | −6194 | −5699 |

Nov | −2494 | −3153, |

Dec | −4701 | −5941, |

Evaporative

layer to be applied inside surfaces of outer walls in Mediterranean climate is

a novel approach. This novel element has been designed and its performance has

been investigated in this study.

Simulation

results indicate that this layer prevents heat gain from outer walls and

provides additional cooling during summer period in İzmir conditions.

This layer

can also be used in winter conditions as dry.

The other

benefit of this layer is improving thermal comfort conditions of the indoor

environment.

It has been shown that evaporative layer is the best solution for İzmir. In case of proposed evaporative layer, annual energy saving is higher comparing to the thermal insulation. The proposed layer reduces annual building energy requirement from 134,391 kWh to 61,380 kWh and the saving of energy is about 73,012 kWh annually.

[1] Stazi, F., Bonfigli, C., Tomassoni, E., Di Perna, C., & Munafò, P.,

2015. The effect of high thermal insulation on high thermal mass: Is the

dynamic behavior of traditional envelopes in Mediterranean climates still

possible? Energy and Buildings, 88, 367-383.

[2] ASHRAE, 2001. International Weather for Energy Calculations (IWEC Weather Files) User Manual and CD-ROM. Atlanta USA.

Follow us on social media accounts to stay up to date with REHVA actualities

0