Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

L. Kooi | A.K. Mishra | M.G.L.C. Loomans |

Department of the Built Environment, Unit

Building Physics and Services, Eindhoven University of Technology, Eindhoven,

the Netherlands | Department of the Built Environment, Unit

Building Physics and Services, Eindhoven University of Technology, Eindhoven,

the Netherlands | Department of the Built Environment, Unit Building Physics and Services,

Eindhoven University of Technology, Eindhoven, the Netherlands |

L. Pennings | J.L.M. Hensen | |

Strukton Worksphere, the

Netherlands | Department of the Built Environment, Unit

Building Physics and Services, Eindhoven University of Technology, Eindhoven,

the Netherlands |

Existing

guidelines on monitoring of Indoor Climate Quality (ICQ) do not adequately

address long term monitoring. A better understanding of the collection and

analysis of monitored data, extending over a long-time period is required. This

study aimed at addressing the aforementioned research gaps. The study took

place in two office buildings, during two periods each: February & May

(case I) and April & June (case II). Thermal environment data was obtained

across several locations in the room. Results showed that measurement of

temperature was most critical in the open-plan office floors. Local heat

sources had a significant influence on the measured temperatures. To collect

representative data with the help of building management system (BMS) sensors,

existence and fluctuation of local heat sources should be considered at the

start of the ICQ assessment. Based on this information, the minimal distance

between BMS sensor and workplace location can be determined. In the design

process, the field study protocol can be used as a tool to predict the number

of sensors and distance from occupants.

Recent

studies have put focus on the importance of monitoring buildings during their

operation and maintenance phases [1–4]. The body of data obtained through such

monitoring provides essential information about a building’s energy consumption

and Indoor Climate Quality (ICQ) and can be used to control and optimize its

performance [1–3,5]. The accuracy and applicability of the conclusions from the

gathered data depends on the quality of the data (reliability) gathered and

data interpretation (data-analysis) [6]. Compared to energy consumption and

service control, ICQ monitoring is less addressed. Current standards like ISO

7730 [7], NEN-EN 15251 [8], ANSI/ASHRAE standard 55 [9] and Dutch ISSO

guidelines also do not provide details for long-term ICQ monitoring [6,10–12].

Drawing uninformed conclusions during monitoring and analysis may affect the

comfort perception, well-being, and productivity of occupants [8,12–14] and

building energy use [6,8,15]. Reliability of the ICQ data is strongly dependent

on sensor location. Sensor location is usually chosen in accordance with

guidelines, as from ISSO publication 31 [16]. However, such guidelines are

cursory, making ICQ assessment at a detailed level a topic in need of

comprehensive investigation. For this reason, the current work investigates the

influence of the location of the building management sensor on its measurement

and recommendations were formulated for long-term monitoring needs.

Indoor

climate of two existing open-plan offices in the Netherlands were monitored,

during two periods each (Table 1). Both environments are

ventilated, cooled and heated by an induction system and regulated by one BMS

sensor located on the wall (at 1.5 m height from floor). The BMS sensor

records indoor temperature and relative humidity every five minutes. Data from

the BMS sensor is analysed with the help of a data platform [17]. In both case

studies is the data platform developed by the same company, to oversee

buildings remotely and to optimize their maintenance. In both locations,

occupants have the possibility to effect small changes to air temperature by

local thermostats and are able to avoid direct sunlight by using indoor

sunscreens. There was no outdoor sun protection.

Table 1.

General information about the case studies. (Measurement period 1 and 2 are

defined as M1 and M2).

Case | Year of construction | Location | Surface area [m²] | Max. # occupants | Parameters BMS sensor | M1 | M2 |

Case A | 2010 | Son | ~140 | 41 | -Exposed temp | Feb | May |

Case B | 1956 | ‘s-Hertogenbosch | ~620 | 68 | -Exposed temp -Relative humidity | Apr | Jun |

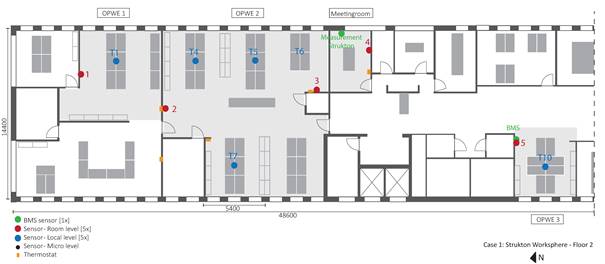

Indoor

climate data from different locations in the open-plan work environment was

collected and compared with the data from the data platform to assess

differences in ICQ over the whole floor. The measurement locations have been

given in Figure 1 and Figure 2. At

the start of the measurement period, the measurement equipment was calibrated

and the BMS sensors’ measurements were compared against the calibrated

equipment to avoid discrepancies.

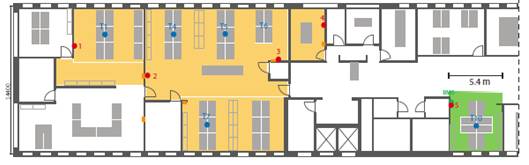

Figure 1.

Floor plan second floor of Case A. In the gray

accented areas, objective measurements were performed (Open-plan work

environments 1, 2 and 3 and Meetingroom).

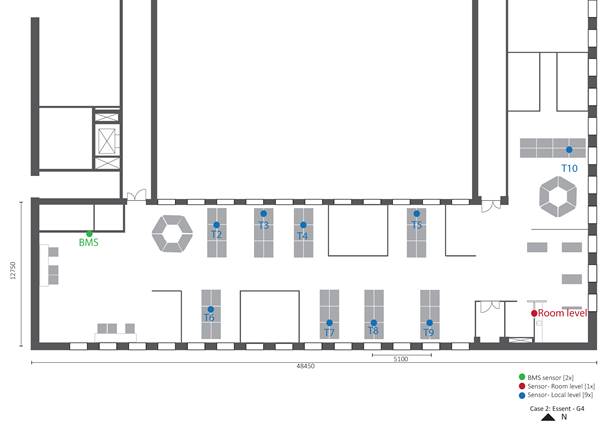

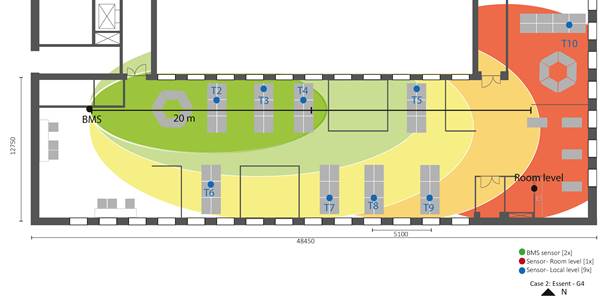

Figure 2.

Floor plan for observed area of Case B. The BMS sensor is located in the left corner.

An extra room sensor was placed on the right side of the floor. The sensors at

local level are illustrated in blue.

Objective

measurements were undertaken at three levels: room level, local level and micro

level (Figure 3). The room level gave insight to the overall

conditions of the room and was measured with the help of two kinds of sensors:

‘BMS sensor’ and ‘room sensor’. Room level sensors were placed according to the

Dutch guidelines [16,18]. At this level, air temperature, relative humidity and

CO2-concentration were determined every 2 minutes

using transmitters (Table 2). Since the recorded air

temperature may be affected by radiant sources and may not provide a measure of

solely the air temperature, we refer to the measured values as ‘exposed temperature’ (ET).

Figure 3.

Images from Case B (a-c) and Case A (d-f), depicting the buildings and the

different localities of monitoring: b) & e) room level, c) & f)

local/desk level. The micro environment for temperature measurements is

depicted in g) where the star marks sensor location.

Local level

thermal conditions around workstations were measured in the same way as the

room level. At this level, the sensors (GD47 transmitter) were placed near each

workplace group, at a height of 1.1 m above the floor. Micro level

measurements focused on individuals, i.e., the thermal condition around a

person. On each measurement day, four to six of the participants who had

volunteered to be a part of the study were selected to represent random

location on the floor-plan. IButtons (DS1921, Maxim)

were placed next to the chair of the participant, where they recorded ET every

minute. The best location for the iButton was

explored through a set of preliminary measurements to limit the influence of

the body heat.

Table 2. Overview of the measurement equipment.

Measurement | Device | Type | Accuracy | |

Room level & Local level | T/RH/CO2 sensor | Eltek GD47 Transmitter | Temp. |

|

RH |

| |||

CO2 |

| |||

Data logger | Grant SQ 1000 series | - |

| |

Micro level | iButton | Maxim DS1921 | Temp. |

|

The

collected data was collated using Matlab (R2016b).

IBM SPSS Statistics 23 was used for statistical analysis. Only data

corresponding to working hours (8:00 AM-06:00 PM) was processed. Preliminary

analysis showed the indoor conditions did not correlate with outdoor weather

conditions, and hence observations for both periods were analysed together. The

two buildings were examined separately. Statistically significant differences

were examined with the Mann-Whitney U test. Significance was tested at 5%

level. Correlations were determined by the ‘Pearson product

moment correlation’.

Data from room, local and micro level were compared

and linked to the BMS data. In both case studies, differences in CO2-concentration

and relative humidity between the room sensor and local sensor were relatively

small and no practically significant difference between the measured values

could be found. Based on these results it may be concluded that the original

BMS sensor location could provide representative data related to the CO2-concentration and relative humidity for the examined

open plan spaces.

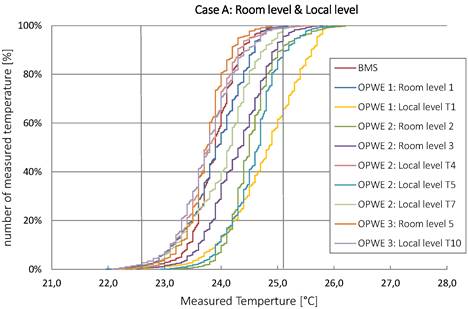

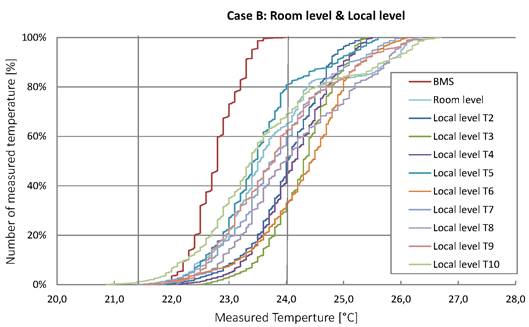

However,

variation of ET through the open-plan work environments was significant. The

results have been plotted in cumulative frequency distribution (CFD) graphs (Figure 4).

Differences between sensors are smaller when data behaves in a similar pattern

and plotted lines had a similar temperature range. In the best case, the

difference between the BMS data and the rest of the monitoring levels are

limited, so that BMS data is representative of the local conditions.

Figure 4.

CFD-graph from room level (top) and local level (bottom) of Case A & Case

B. The graph shows the distribution (smallest to largest) and frequency temperature

range of each sensor. The temperature range of the BMS sensor is illustrated

with the vertical lines.

For most

cases, the local ET exceeded BMS measurements by 1°C or

more. The only exception was for OPWE 3 at Case A (Figure 1). We

believe the differences in the ETs were mainly due to local heat sources, for

example, the occupants, computers, and solar radiation through windows.

Therefore, the distance between BMS sensor and workplaces is important when it

comes to reliability of the measurements. In both locations, the BMS sensors

were more than 3 m away from occupied workplaces. When distance between room

level and local level sensors were less than 3 m, the differences in

recorded ETs were minimal. For instance, in OPWE 3 of Case A, the BMS sensor

was within 2 m of the work stations. No significant difference could be

found between the ETs at local level and BMS. The impact of the distance

between sensors is clarified using correlations between the BMS, room, local

and micro sensors. Table 3 and Table 4 show

the correlations for both case studies. In Case B, larger distance between

sensors resulted in weaker correlations (Figure 5).

Better correlation may thus be achieved between local and BMS ETs by using a

larger number of BMS sensors, spread across the open plan workspace. Notice for

example in Table 3 that the room sensor position has a

stronger correlation with local & micro level than the BMS position. Thus,

a minimum number of BMS sensors are required in order to have a representative

indication of the ICQ.

For Case A,

because the floor has been divided into multiple spaces (OPWE 1, 2 & 3 and

Meeting room) the situation was different. Regardless of the distance between

sensors, the sensor located in a different space always had a weak correlation

with the BMs sensor (r < 0.306, p < 0.05) (Figure 6). To

collect representative thermal data in Case A, a BMS sensor would be required

for each space. Adding extra room sensors increases the strength of the

correlations in both cases, where the closest room sensor has the strongest

correlation with the relevant local and micro sensor. Overall, ET at room level

(BMS sensor and room sensors) was better correlated to ET at local level than

the temperature at mirco level.

Table 3.

Pearson product moment correlation BMS-Room-Local-Micro (Case B) for four local

situations, here p < 0.001. The distance between sensors has

influence at the strength of the correlation (T4 strongest correlation with the

BMS sensor, T10 weakest correlation). Moreover, a weaker correlation is found

on the south side of the floor plan, due to solar radiation (T6).

Table | BMS senor | Room sensor | Local sensor | |||

T4 | BMS ~ Local T4 | 0.847 | Room ~ Local T4 | 0.717 | ||

BMS ~ Micro T4 | 0.434 | Room ~ Micro T4 | 0.685 | Local T4 ~ Micro T4 | 0.755 | |

T6 | BMS ~ Local T6 | 0.687 | Room ~ Local T6 | 0.678 | ||

BMS ~ Micro T6 | 0.512 | Room ~ Micro T6 | 0.655 | Local T6 ~ Micro T6 | 0.624 | |

T8 | BMS ~ Local T8 | 0.657 | Room ~ Local T8 | 0.881 | ||

BMS ~Micro T8 | 0.634 | Room ~ Micro T8 | 0.704 | Local T8 ~ Micro T8 | 0.868 | |

T10 | BMS ~ Local T10 | 0.095 | Room ~ Local T10 | 0.891 | ||

Figure 5.

The influence of distance between sensors and solar radiation for the

correlation between the BMS sensor and local sensors.

The

relation with micro level was more complex. Only 65% of the correlations (local

with micro) were of a high enough value (Table 3 & 4).

Due to the large differences in micro ET for each table and each person, no

reliable relationship or trend could be found. Accurate measurements at micro

level are dependent on several parameters. For instance, the activity of the

person sitting in the chair, the position of the chair and distance to local

heat sources can be important information to explain differences in micro

measurements.

Table 4.

Pearson product moment correlation BMS-Room-Local-Micro (Case A) for three

local situations. Here p < 0.001.

Table | BMS senor | Room sensor | Local sensor | |||

T1 | BMS ~ Local T1 | 0.306 | Room ~ Local T1 | 0.855 | ||

BMS ~ Micro T1 | 0.401 | Room ~ Micro T1 | 0.357 | Local T1 ~ Micro T1 | 0.352 | |

T5 | BMS ~ Local T5 | 0.267 | Room ~ Local T5 | 0.728 | ||

BMS ~ Micro T5 | 0.279 | Room ~ Micro T5 | 0.479 | Local T5 ~ Micro T5 | 0.492 | |

T10 | BMS ~ Local T10 | 0.955 | Room ~ Local T10 | 0.941 | ||

Figure 6.

The correlation is weak when sensors are not located in the same room

(regardless of the distance between sensors.

Though

quantitative conclusions from this study are case specific, certain qualitative

conclusions regarding objective data measurement for indoor climate quality

monitoring may be provided. In order to have a representative indication of the

ICQ, the maximum distance between sensors should be considered during design of

the monitoring system. The number of sensors depends on the floor plan design

specifically, obstacles and boundaries. The number of sensors can be optimized

by test measurements on different measurement levels.

The spacing

of sensors can also be affected by local heat sources as they can influence the

ET. If local heat sources, such as occupancy and solar radiation, are

relatively consistent, CO2-concentration, relative

humidity, and ET can be determined at room level with a distance of 3 m to

the workplaces, assuming the ventilation system is effective. Moreover, a

higher frequency for recording data would be recommended to register

fluctuations in ET. In Case A and Case B, local heat sources cannot be ignored

in the comfort analysis due to changing occupancy and lack of outdoor shading.

Hence, for these office spaces, BMS sensors need to be placed at a closer

distance (< 3 m) to workstations.

This study

provides results from field measurements that can aid decision making regarding

the position of BMS sensors and the collection of objective data in open-plan

offices. Results of the objective measurements show little differences in CO2-concentration and relative humidity between BMS, room

and local sensors. A larger difference is found for ETs. The existing BMS

sensors did not yield a representative indication for the complete floor space

when it came to ET. Local heat sources and distance between sensors have a

significant influence on the measured value of ET. These parameters need to be

considered during design of the monitoring system. Floor plan (enclosed spaces,

obstacles, and floor area) and the existence and fluctuation of local heat

sources influence sensor positioning requirements. The field study protocol as

described in this method is useful for determining

monitoring level and sensor separation.

As results

of this study are based on just two office buildings with an induction system

under specific weather conditions, it is recommended to further develop the

application of the method in more varied office settings, occupant

demographics, and outdoor weather conditions to further the conclusions and

recommendations formulated herein.

Cooperation

of all the occupants during the measurements is acknowledged gratefully. Our

thanks to Wout van Bommel

for the help and cooperation with the field measurements.

[1] A. Heller, M. Uhd,

P. Fischer-Nilesn, J.K. Frederiksen, H. Juhler-Verdoner, E. Hansen, B. Torntoft,

T. Kiar, H. Kronborg, F.

Petersen, J. Andreasen, N.J. Andersen, S. Kuehn, K.E. Eriksen, P. Sattrup, S. Konmgebro, J. Norgaard, Smart Buildings; Combining energy efficiency,

flexibility and comfort, 2015. https://stateofgreen.com/en/profiles/state-of-green/news/new-smart-buildings-white-paper-published.

[2] T. Ruponen,

Improving energy performance of buildings through exploitation of available

data, Aalto University, 2016.

[3] A. Mahdavi, M. Taheri, An ontology for

building monitoring, Build. Perform. Simul. 0 (2016) 1–10.

[4] D. Raimondo, S.P. Corgnati,

B.W. Olesen, M. Filippi, Indoor and Energy quality

assessment in buildings, University of Turin, 2012.

[5] P. Huovila, A. Lupisek, P.H. Lefebvre, P. Steskens,

Indoor Performance and Sustainability; Monitoring and evaluation, in: European

commission, 2010: pp. 557–564.

[6] D. Heinzerling, S.

Schiavon, T. Webster, E. Arens, Indoor environmental

quality assessment models: A literature review and a proposed weighting and

classification scheme, Build. Environ. 70 (2013) 210–222.

[7] ISO, ISO 7730, Ergonomics of the thermal

environment; Analytical determination and interpretation of thermal comfort

using calculation of the PMV and PPD indices and local thermal comfort

criteria, International Organization for Standardization, 2005.

[8] CEN, NEN-EN 15251; Indoor environmental

input parameters for design and assessment of energy performance of buildings

addressing indoor air quality, thermal environment, lighting and acoustics,

Brussels, 2007.

[9] ASHRAE - ANSI/ASHRAE Standard 55-2013,

Thermal environmental conditions for human occupancy, American Society of

Heating, Refrigerating and Air-Conditioning Engineers, 2013.

[10] P. De Wilde, The gap between predicted and

measured energy performance of buildings: A framework for investigation, Autom. Constr. 41 (2014) 40–49.

[11] G. Augenbroe, C.-S.

Park, Quantification methods of technical building performance, Build. Res.

Inf. 33 (2005) 159–172.

[12] J.H. Choi, V. Loftness,

A. Aziz, Post-occupancy evaluation of 20 office buildings as basis for future

IEQ standards and guidelines, Energy Build. 46 (2012) 167–175.

[13] P.M. Bluyssen, Towards new methods and ways to create healthy and

comfortable buildings, Build. Environ. 45 (2010) 808–818.

[14] A.K. Mishra, M.G.L.C. Loomans,

J.L.M. Hensen, Thermal comfort of heterogeneous and

dynamic indoor conditions — An overview, Build. Environ. 109 (2016)

82–100.

[15] A.I. Dounis, C. Caraiscos, Advanced control systems engineering for energy

and comfort management in a building environment-A review, Renew. Sustain.

Energy Rev. 13 (2009) 1246–1261.

[16] ISSO - publicatie

31, Meetpuntenenmeetmethodenvoorklimaatinstallaties, Kennisinstituutvoorinstallatietechniek,

1995.

[17] StruktonWorkspere, PULSE, (2015).

[18] B. Ankersmit, A.W. Brokerhof, W. Kragt, M.H.L. Stappers, N. Duggen, J. Jonge,

de, J. Schonewille, H.H.E.W. Eijdems,

M.H.J. Martens, H.L. Schellen, M. Otte,

J.M. Tegelaers, Meten van

het binnenklimaat; waarom, waar?,InstituurCollectie Nederland; Ministerie van Onderwijs, CultuurenWetenschap,

2010.

[19] ASHRAE, Performance Measurement Protocols for

Commercial Buildings, (2010) 1–162.

[20] K. Ackerly, G.S. Brager, E. Arens, Data Collection

Methods for Assessing Adaptive Comfort in Mixed-Mode Buildings and Personal

Comfort Systems, University of California, 2012.

Follow us on social media accounts to stay up to date with REHVA actualities

0