Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

Alireza Afshari | Olli Seppänen |

Department of the Built Environment, Aalborg UniversityA.C. Meyers Vænge 15, A, 6224, 2450 København SV, Denmark* Corresponding Author aaf@build.aau.dk | Nordic Ventilation Group & FINVACSitratori 5, 00420 Helsinki, Finlandolli.seppanen@finvac.org |

Measures to reduce exposure to indoor air pollutants and potential adverse health effects generally fall into three main categories: source control, ventilation control, and removal control. Source control means to eliminate individual sources of pollution or to reduce their emissions. Source control is usually the most effective way to improve indoor air quality. Another approach to diluting indoor air-pollutant concentrations to ensure adequate indoor air quality is to increase outdoor air coming indoors. Portable room air cleaners can clean the air in a polluted room when continuous and localised air cleaning is needed. For air-cleaning devices to be effective, the air-cleaner capacity must match the ventilation rate of the room. This cleaning technology is useful when there is no opportunity to clean the supply air by filtration (i.e., for buildings with a natural ventilation system or an exhaust ventilation system). Consumers should also consider possible side effects, such as noise and ozone generation when considering air-cleaning devices.

Portable air cleaners use different technologies to remove airborne particulates and gaseous pollutants. Particulate matter comprises small particles of solid or liquid droplets suspended in the air, such as airborne dust, pollen, viruses, and bacteria. Gaseous pollutants include volatile organic compounds, carbon monoxide, nitrogen oxide, and aldehydes.

Portable air cleaners use three types of technology to remove particulate matter and gaseous pollutants from the air. These technologies can be divided into three categories.

· Particle removal technology: The most commonly applied methods are fibre filtration, electrostatic precipitators (ESPs) and ionisers.

· Gas purification technology: The most commonly applied methods are adsorbent media air filters, such as activated carbon, chemisorbent media air filters, photocatalytic oxidation, plasma, ozone generators, and plants.

· Far-ultraviolet (UV-C) germicidal technology: The frequently adopted method is UV radiation.

It is crucial to understand the difference between the two parameters that influence the performance of air-cleaning devices:

· The efficiency of an air-cleaning device is a fractional measure of its ability to reduce the concentration of air pollutants that pass through the device. The fractional efficiency of a device is measured in a laboratory, where all relevant variables are controlled.

· The effectiveness of an air-cleaning device or system is a measure of its ability to remove pollutants from the spaces it serves in real-world situations.

The most helpful parameter for understanding the effectiveness of portable air cleaners is the clean air delivery rate (CADR), a measure of a portable air cleaner’s delivery of relatively clean air, expressed in cubic meters per hour (m³/h). A higher CADR relative to the room size increases the effectiveness of a portable air cleaner. A CADR can theoretically be generated for either gases or particles; however, the current test standards only rate CADRs for particle removal (AHAM, 2013).

In a review, Cheek et al. (2020) analysed the influence of air cleaners on PM2.5 concentrations in the indoor environment. The authors concluded that air cleaners reduced PM2.5 concentrations by between 22.6% and 92.0% in homes and 49% in schools. This variability can be attributed to various factors, including study design, intervention duration, CADR, and user compliance.

Air-cleaning devices are commonly marketed as benefitting air-pollutant removal and, consequently, improving the indoor air quality (Shaughnessy and Sextro, 2006). Depending on the cleaning technology, air cleaners may generate undesired and toxic by-products and contribute to secondary emissions, such as ozone and aldehyde, and their effectiveness may vary (Novoselac and Siegel, 2009; Ardkapan et al., 2014).

While portable air cleaner equipped with fibre filters are designed to remove particles, they are primarily ineffective for odours. In addition, when pollutants such as bacteria and mould are trapped on the fibre filters, they may multiply over time if filters are not replaced, which can increase unpleasant smells (Kerins, 2018). To summarise, the following parameters must be considered to select a portable air cleaner for a room that can effectively remove particles.

· CADR,

· energy efficiency,

· noise,

· service and maintenance,

· placement of the air cleaner, and

· possible adverse effects of the air cleaner on the indoor air quality, such as ozone generation.

Among various air-cleaning techniques, fibre air filtration is the most widely used and developed air-cleaning method. There are various qualities of fibre filters available in the market. The efficiency levels of the fibre filters are classified as coarse, medium, fine, efficient particulate air, high-efficiency particulate air (HEPA), and ultra-low penetration air (ULPA) filters. When an airstream containing airborne particles passes through a filter, the particles are collected using five mechanisms: interception, impaction, diffusion, electrostatic attraction, and sedimentation. The first three of these are predominantly governed filtration mechanisms. The particle collection efficiencies of these five mechanisms are determined by the filter media properties, for example, the fibre diameter, packing density, media thickness, and working conditions, such as airflow velocity (Shi, 2012; Liu et al., 2017). Fibre filtration requires the frequent need to exchange both filters to maintain the desired level of filtering efficiency.

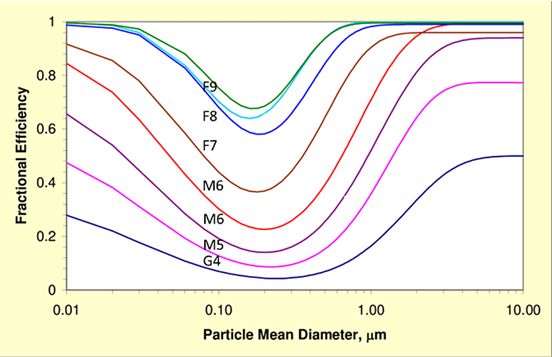

Among the above filters, coarse, medium, and fine filters are commonly used in commercial and residential buildings. The HEPA and ULPA filters are commonly used in cleanrooms, laboratories, factories, and hospitals. The filtration efficiencies of HEPA and ULPA filters are substantially high, while the corresponding pressure drops are also high, which means that they are uneconomical for commercial and residential buildings. Figure 1 illustrates a composite of seven filter models based on measurements according to the standard ASHRAE 52.2-2012.

The cheapest filter is not necessarily the lowest cost filter because three factors determine the filter cost: the initial investment and maintenance, energy use, and disposal. Initial investment and maintenance account for about 18.5% of the cost to operate a filter, whereas the energy use is 81% and disposal is 0.5% (National Air Filtration Association, 2021).

Figure 1. Composite of seven filter models based on measurements according to the standard ASHRAE 52.2-2012; adapted from Kowalski and Bahnfleth(2014).

Often, HEPA filters are used in portable air cleaners. The HEPA material can remove particles, including 99.97% of particulate matter, smog, and microorganisms at a size of 0.3 µm. The filtration efficiency increases for particle diameters both less than and greater than 0.3 µm. For instance, a HEPA H13 filter can remove up to 99.95% of maximum penetration size particles. According to EN-1822, the filters must be tested with the particle of maximum penetration size. The most penetrating particle size for each filter ranges from 0.12 to 0.25 µm (EN 1822, 1998). The size of the coronavirus that causes COVID-19 is estimated to be between 0.12 and 0.16 µm, and the minimum size of a respiratory particle that can contain SARS-CoV-2 is approximately larger than 4.7 µm. In addition, the size of the particles decreases due to water evaporation on the particle surface (Lee, 2020). Therefore, portable air cleaners equipped with HEPA filters can reduce the aerosol transmission risk for SARS‐CoV-2. Such devices must have a CADR that is large enough for the room size or area in which it will be used.

While higher performance air cleaners that use HEPA filters work efficiently in laboratory tests, their effectiveness in typical residential buildings is less clear. Several studies have shown that portable air cleaners equipped with a HEPA filter in residential buildings can reduce the average indoor PM2.5 by approximately 29% to 62% (Afshari et al., 2011; Allen et al., 2011).

Ward et al. (2005) evaluated the air-cleaner effectiveness in terms of the outdoor and indoor particle concentration with air cleaners relative to the indoor concentration without air cleaners. The authors found that the relative effectiveness of air cleaners for reducing occupant exposure to particles of outdoor origin depends on several factors, including the type of heating, ventilating, and air-conditioning (HVAC) filter, HVAC operation, building air exchange rate, particle size, and duration of elevated outdoor particle concentration. Maximum particle reductions of 90%, relative to no stand-alone air cleaner, are predicted when three stand-alone air cleaners are employed, and reductions of 50% are predicted when one stand-alone air cleaner is employed (Ward et al., 2005).

In the USA and Hong Kong, the Hospital Authority recommended portable HEPA cleaners in clinics and other healthcare settings when the central HVAC system cannot provide an adequate air change rate or when the system undergoes repairs (CDC, 2003).

Qian et al. (2010) studied the particle removal efficiency of the portable HEPA air cleaner in a simulated hospital ward. The results reveal that the HEPA filter can effectively decrease the particle concentration level. The effective air change rate achieved by the HEPA filter (for particle removal only) is from 2.7 to 5.6 ACH in the ward. The authors found that the tested HEPA filter produced global air circulation in the test room (The air change rate is 4.9 for a room of 6.7 m × 6 m × 2.7 m) when the airflow rate was approximately 535 m³/h, and the airflow in the ward was nearly fully mixed. The authors concluded that the strong HEPA filter airflow completely destroyed the ward’s originally designed airflow pattern. The filter efficiency was 98% for particles larger than 10 µm, 95% for particles of 5 to 10 µm, 80% for particles of 1 to 5 µm, and 53% for particles of less than 1 µm.

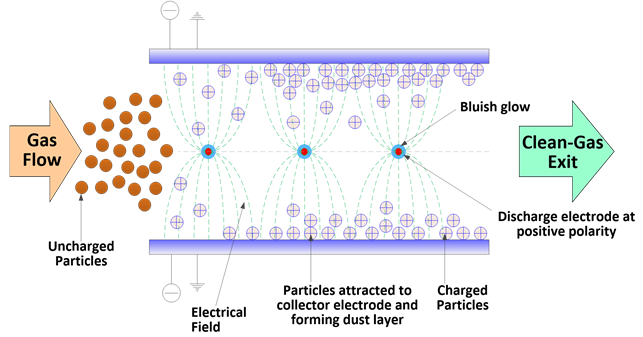

Electrostatic precipitation uses electrical field forces on charged particles to separate them from a gas stream. The particles are deliberately charged and passed through an electrical field, causing the particles to migrate towards an oppositely charged electrode that acts as a collection surface (Figure 2). Commercial ESPs accomplish charging using a high-voltage, direct-current corona surrounding a highly charged electrode, such as a wire. The large potential gradient near the electrode causes a corona discharge comprising electrons. The gas molecules become ionised with charges of the same polarity as the wire electrode. These ions collide with and attach to the aerosol particles, charging them (Hinds, 2012; Afshari et al., 2020). This high level of voltage may cause some other reactions, such as ozone generation. Ozone can be generated from a corona discharge and the ionisation process (Boelter and Davidson, 1997). The ESPs with a fan and collection plates and the smaller ion generators, which often do not have a fan and may or may not have collection plates, are ionisers. They charge incoming particles with a corona and may produce ozone (AHAM, 2009). However, smaller particles have higher mobility and are more easily attracted by lower charge levels. In addition, the electrostatic deposition velocity of a small particle is higher than the diffusion and gravitation velocities.

Electrostatic precipitators can offer some benefits over other highly effective air filtration technologies. For example, HEPA filtration requires filters and may become ‘sinks’ for some harmful forms of bacteria and cause high-pressure drops. A common method of classifying ESPs is the number of stages used to charge and remove particles from a gas stream. When the same set of electrodes is used for both charging and collecting, the precipitator is called a single-stage precipitator. Single-stage ESPs use very high voltage (50 to 70 kV) to charge particles. If different sets of electrodes are used for charging and collecting, the precipitator is called a two-stage precipitator. The direct-current voltage applied to the wires is approximately 12 to 13 kV (US EPA, 2002). An experimental study shows that an ESP that uses anticorrosive materials can generate numerous unipolar ions while producing only a negligible ozone concentration and achieve a strong collection performance of more than 95% for ultrafine particles (UFPs), while only using 5 W and generating a pressure drop of 5 Pa per 1 200 m³/h (Kim et al., 2010).

The ESPs were tested in laboratory settings to ensure that the equipment meets specific quality criteria concerning air-cleaning performance and does not produce harmful substances. However, gaps exist between the laboratory test procedures and using the equipment in ‘real-life’ situations. Short-term studies (less than one week) of ESPs in chambers demonstrated that ESPs could achieve more than 50% efficiency for UFPs (Kinzer and Moreno, 1997). Ardkapan et al. (2014) evaluated five portable air-cleaning technologies, including an ESP with an airflow rate of 300 m³/h to determine the cleaners’ effectiveness in removing UFPs. Measurements were conducted in a test chamber. The authors reported that the effectiveness of the ESP to remove UFPs was 38%. Zuraimi et al. (2011) examined 12 different air-cleaning technologies, including an ESP with an airflow rate of 800 m³/h to determine the cleaners’ effectiveness in removing UFPs. The authors found that the ESP effectively removed 95% of UFPs. Morawska et al. (2002) studied the performance of a two-stage ESP filter in an ASHRAE test rig to determine the efficiency of particles ranging from 0.018 to 1.2 µm. The authors reported single-pass efficiencies ranging from 60% to 98% for particles smaller than 0.1 µm, with lower efficiencies noted at high face velocities. Shaughnessy et al. (1993) tested an ESP in office rooms with smoking. They reported that the CADR was reduced by 38% for the ESP.

Figure 2. Schematic of the basic processes of an electrostatic precipitator (Source: modified from a guide document published by the Ohio Environmental Protection Agency, USA, accessible at www.epa.state.oh.us/portals/27/engineer/eguides/electro.pdf).

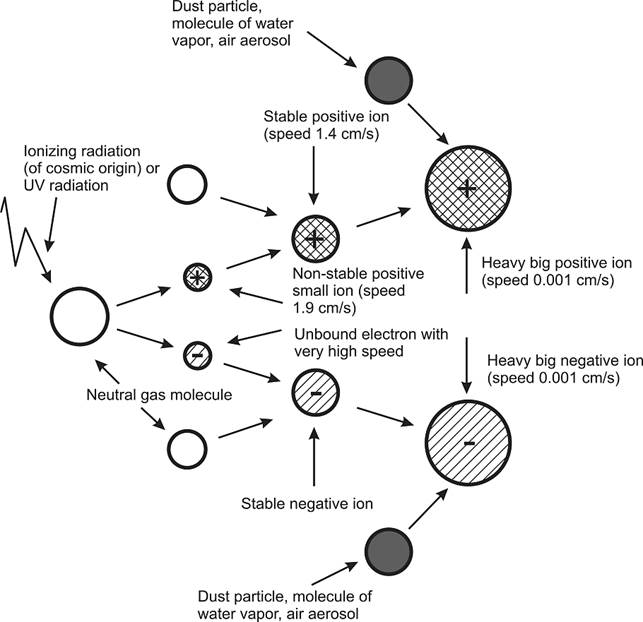

Air cleaners called ‘air ionisers’ work similarly to ESPs. Ionisers use high voltage to electrically charge (usually negative) particles moving through the ioniser or air molecules (Figure 3). Positively charged ions are called cations; negatively charged ions are anions. These charged molecules are called ions, and the ions attract oppositely charged surfaces or particles, forming them into larger particles that can fall through the air or be adsorbed into surfaces, such as carpets or curtains, that have gained a positive charge through static electricity (Tanaka and Zhang, 1996). In an electrostatic air cleaner, the negatively charged particles are attracted to a positively charged collector plate, but a regular ioniser does not have a collecting plate.

Air ionisation has been used to clean the air in an internal environment by reducing particles and gases (Daniels, 2007). However, Waring and Siegel (2011) studied an ion generator in a 27 m³ residential room. The authors concluded that the ion generator used in their investigation increased concentrations of UFPs, ozone, and, to a lesser extent, formaldehyde and nonanal. It also slightly decreased concentrations of fine particles.

Ions also have antibacterial effects and may decrease the microorganisms and allergens in the air (Goodman and Hughes, 2004). The undesirable effects of air ionisation include ozone (O3) emissions, which can react with terpenes to yield secondary organic aerosol, carbonyls, carboxylic acids, and free radicals. The authors concluded that using a corona causes ion generators to emit ozone at measured rates of 0.056 to 13.4 mg/h. The authors also reported that CADRs for portable ion generators range from 0 to 90 m³/h, at least an order of magnitude less than HEPA cleaners.

Daniels (2001) reported that recent developments in large ion generator design and operation have led to the commercial availability of energy-efficient units. These units can now produce controlled outputs of specific ions on demand, while minimising the formation of undesirable by-products, such as ozone.

Figure 3. Principle of ion particle formation in the atmosphere (Černecky and Pivarčiová, 2015).

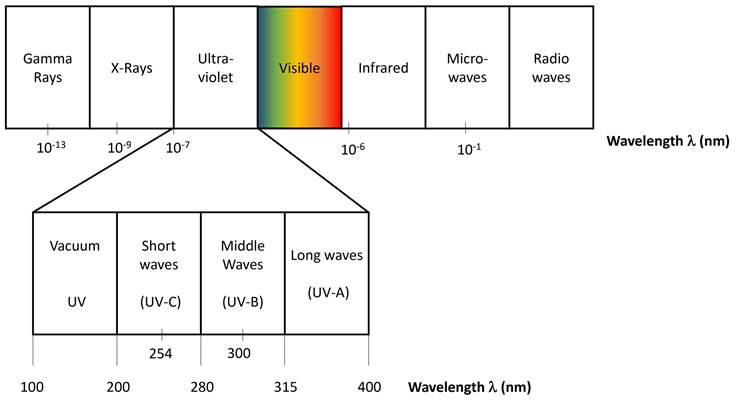

Germicidal ultraviolet (UVGI) uses ultraviolet light in the UV-C wavelength range (200 nm to 280 nm) to inactivate microorganisms. Most systems use low-pressure mercury lamps, which produce a peak emission at around 254 nm. The effectiveness of UV-C is directly related to the intensity and exposure time.

Environmental factors, such as humidity, airborne mechanical particles, and distance, can affect the performance of UV fixtures (American Air and Water, 2021). For instance, the coronavirus that causes COVID-19 is susceptible to UVGI, so if it is irradiated for a certain amount of time, it is inactivated. Three air disinfection applications are on the market. One application is upper-room germicidal systems, and the other application is UVGI cleaners used in HVAC systems and portable air cleaners. The upper-room systems can reduce the amount of active virus in the air by an amount equal to 10 or more air changes per hour of outdoor air at a much lower energy cost (Riley et al., 1976). The other application, UVGI cleaners in HVAC systems, is designed to destroy/inactivate viruses in the flowing air stream as they pass through the device. Portable air cleaners often incorporate UV-C lamps to destroy and remove viruses trapped on air-filter medium surfaces. Good evidence exists that UVGI with UV-C light is likely a viable decontamination approach against SARS-CoV-2, for instance, for unoccupied rooms (SAGE – Environmental and Modelling Group, 2020).

In addition, UV irradiation can denature microorganism DNA, causing death or inactivation (Liltved, 2000). Further, UV inactivation depends on the microorganism species and environmental conditions, such as temperature and humidity. In laboratory conditions, UVGI is effective against bacteriophages in the air against influenza, and activation reduces with increased humidity for viral aerosols (McDevitt et al., 2012).

Several portable devices are on the market, and all show good single-pass efficiency; however, their effectiveness in a room is dependent on their flow rate relative to the room size. Many devices have insufficient airflow to be effective in practice.

Several researchers have reported the efficacy of UV-C in reducing the total and viable particle counts in highly controlled operating room environments (Davies et al., 2018). Air filtration and disinfection units combining HEPA filtration and UV-C disinfection technologies may reduce the potential for patient infection.

In addition, UV-C for surface and air decontamination must consider health and safety issues. Direct exposure of the skin and eyes to UV-C radiation from some UV-C lamps may cause painful eye injury and burn-like skin reactions. Therefore, UV lamps must be located within enclosed or shielded devices or operated when no occupants are present (SAGE – Environmental and Modelling Group, 2020).

Figure 4. The electromagnetic spectrum, with the UV spectrum and the visible spectrum highlighted (Violet Defense, 2017). https://static1.squarespace.com/static/58d3f70c4402432cd581ffa9/t/59a866cacd39c3c68492094c/1504208589083/Guide+to+Understanding+UV+Light.pdf

Filters increase resistance to airflow, increasing the energy use and running cost of the system, and they require regular maintenance. Following the Eurovent 4/11 guidelines, the yearly energy use of air filters can be determined as a function of the volume flow rate, fan efficiency, operation time, and average pressure drop. The related energy use during a period can be calculated from the integral average pressure drop. Among various air-cleaning techniques, fibre air filtration is the most widely used and developed air-cleaning method.

Stephens et al. (2009) presented the results for four months of detailed energy monitoring of two air-conditioning systems in a test home. The authors stated that if a high-efficiency filter increases the total system pressure by approximately 40%, the results indicate that energy use generally did not differ with high-efficiency filters compared to low-efficiency filters and that other factors should govern filter selection. These results suggest caution when assuming that high-efficiency filters require more energy than low-pressure-drop filters in residential HVAC systems. Parker et al. (1997) measured a 4% to 5% airflow rate reduction when replacing standard disposable filters with high-efficiency pleated filters. Kim et al. (2009) found that the range of airflow reductions due to filters are 5% to 10% from the recommended airflow rates.

Zuraimi et al. (2016) examined two portable air cleaners: one containing a carbon prefilter and HEPA filter and an ESP-based unit. The authors reported that energy performance implications are strongly tied to the fan design and fan speed control. The results revealed that the average initial operating power of the HEPA-carbon-based filter was 125.6 W, which reduced to 12% of its initial value after the half-life of the filter was reached. The mean airflow rate dropped to 49% of its initial value by the half-life of the filter. For the ESP-based unit, the mean operating power measured at various loading intervals was close to one another with no discernible pattern. The airflow rates were almost similar between loadings with a slight reduction in airflow rate only at the half-life. Shaughnessy et al. (1994) reported that the flow rate of an ESP unit remained constant after six months of continuous operation in a smoking office room.

Regarding air ionisers, a study was conducted regarding the effect of air anions on lettuce growth in a plant factory. Song et al. (2014) reported that energy use efficiency concerning air anion treatment was analysed based on the shoot dry weight. The total power use of the air anion treatment was 55.3 kW after four weeks of treatment. The total energy use efficiency based on the shoot dry weight was 0.59 mg/W.

The air ioniser was used in combination with intermediate class filters (M5–F9) to reduce the pressure drop of the filters while maintaining sufficient filtration efficiencies and reducing energy costs (Agranovski et al., 2006; Shi, 2012). The authors demonstrated that ionisation combined with intermediate class filters could enhance the original filtration efficiency for removing airborne particles, aeroallergens, and airborne microorganisms and has a negligible pressure drop increase. However, the reliability of the performance and the potential generation of by-products (e.g., ozone) are critical problems associated with this application.

Regarding UVGI, the energy use of UVGI system is a factor that needs to be considered. Lee et al. (2009) reported that a UVGI air disinfection system affects the energy use of a building in at least four ways: direct energy consumption for lamp operation, increased cooling energy consumption, decreased heating energy consumption, and changes in fan power consumption due to changes in supply air temperature and additional pressure drop caused by the UVGI components in the moving airstream. According to SAGE – Environmental and Modelling Group, 2020, UV carousel devices are typically deployed for between 20 and 45 minutes, depending on the room to be treated, but may also require moving and repeat treatment to overcome shadowing effects.

Foarde et al. (2006) tested in-duct UVGI equipment provided by eight manufacturers. They found that the pressure drop across most systems was less than 8 Pa. Given that this additional peak pressure loss is perhaps 1% to 2% of the total static pressure of a typical supply fan, associated differences in fan power were neglected as negligible. Notably, some of the energy used by the UVGI lamps was translated into heat generation.

Noakes et al. (2015) calculated the plane average irradiance (W/m²) and energy performance coefficient for two devices in four differently sized. Table 1 shows the results obtained by authors. The energy performance coefficient η is calculated as follows: η = Eplane A/W, where Eplane is the plane average irradiance, Ais the area of the zone and Wis the supplied power use.

In all cases, it was assumed that ventilation is provided by mechanical means and that both the ventilation and UV systems operate continuously. Ventilation energy calculations follow Noakes et al. (2012); fan energy is assumed to require 2 W/ℓ/s (56.6 W/ft³/s), while ventilation heat loss is determined using the degree-day approach assuming 50% heat recovery and 2 100 degree-days per year.

Table 1. Variation in energy performance and plane average irradiance with device and zone area (Noakes et al. (2015).

Device | Power | Coverage area | Plane average irradiance | Energy performance coefficient |

1 | 36 | 4 | 0.271 | 0.03 |

1 | 36 | 6.25 | 0.173 | 0.03 |

1 | 36 | 9 | 0.124 | 0.031 |

1 | 36 | 14 | 0.09 | 0.035 |

2 | 72 | 4 | 0.687 | 0.038 |

2 | 72 | 6.25 | 0.472 | 0.041 |

2 | 72 | 9 | 0.338 | 0.042 |

2 | 72 | 14 | 0.267 | 0.052 |

The calculation shows that the energy consumption of the UV devices depends on the specific device power use, how much is converted to UV-C energy, and how well that is distributed within a room. The device 2 contains twice the lamps and uses twice the power of the device 1, but it is clearly more effective, as the average irradiance is between 2.5 and 2.9 times the irradiance in the same sized zone. It can also be seen that the relative energy performance varies within and between devices.

In addition, a potential exists for energy saving. The potential energy savings are because the fan energy required to overcome HEPA static pressure loss, for instance, is greater than the energy consumed by the UVGI lamps (Dreiling, 2008). The combination of UVGI and intermediate class filters (M5–F9) may provide performance virtually equivalent to HEPA filtration, offering the building owner the possibility of reducing energy costs.

The following conclusions can be drawn regarding the performance of portable air cleaners:

· Portable air cleaners reduce exposure to particles indoors and thus improving indoor air quality. Application of portable air cleaners may be a useful strategy to reduce particles in poorly ventilated spaces.

· Portable air cleaners only purify the air in the room in which they are placed, but have the advantage of reducing the risk due to cross contamination between rooms.

· The positioning of a portable air cleaner also affects the overall particle removal and consequently, influences occupants’ exposure to particles.

· Portable air cleaner equipped with HEPA filters have high removal efficiency. However, the filters are also characterized by high pressure drop. They do not produce any ozone or harmful byproducts in the course of operation.

· Electronic air cleaners have a lower pressure drop compared to HEPA filters with comparable particle removal efficiencies and consequently, less energy use.

· Electronic air cleaners produce ozone as a by-product and work by charging particles in the air causing them to stick to surfaces. Furthermore, ozone may even react with existing chemicals in the air to create harmful by-products (e.g. formaldehyde). Exposure to ozone should be limited because of its adverse effects on human health. Inhalation of relatively small amounts of ozone can cause coughing, chest pain, throat irritation, and shortness of breath.

· Exposure to UV light may be harmful in some circumstances.

· Throughout this review, we found that there is a need of additional research for the more reliable conclusions to be made on the long-term performance of portable air cleaners, the noise level of the portable air cleaners when it is working at top capacity, the ozone emission rates, and the energy use and the cost related to it. In addition, examines would be conducted both in the laboratory and field in order to compare the performance of portable air cleaners in the well-controlled laboratory environment to that in real situation.

· Defining the performance criteria that must be met for use of the portable air cleaners and also specifying the testing criteria for room air cleaners.

Afshari, A., Ardkapan, S. R., Bergsøe, N. C. and Johnson, M. S. (2011). Technical solutions for reducing indoor residential exposures to ultrafine particles from second-hand cigarette smoke infiltration. Indoor Air. International Society of Indoor Air Quality and Climate (Proceedings from Indoor Air 2011).

Afshari, A., Ekberg, L., Forejt, L., Mo, J., Ardkapan, S. R., Siegel, J., Chen, W., Wargocki, P., Zurami, S. and Zhang, J. (2020). Electrostatic precipitators as an indoor air cleaner: A literature review, I: Sustainability. 12, 21, 22 s., 8774.

Agranovski, I. E., Huang, R., Pyankov, O. V., Altman, I. S., and Grinshpun, S. A. (2006). Enhancement of the performance of low-efficiency HVAC filters due to continuous unipolar ion emission. Aerosol Sci. Technol. 40:11, 963–968.

Allen, R. W., Carlsten, C., Karlen, B., Leckie, S., Sv, E., Vedal, S., et al. (Date?). An air filter intervention study of endothelial function among healthy adults in a woodsmoke-impacted community. Am. J. Respir. Crit. Care Med. 183, 1222–1230.

American Air and Water. (2021). The Germicidal Nature of UV Light. https://www.americanairandwater.com/uv-facts/uv-germicidal.htm

Ardkapan, S.R., Nielsen, P.V., and Afshari, A.(2014). Studying passive ultrafine particle dispersion in a room with a heat source. Build. Environ. 71, 1–6.

ASHRAE. 2012. ANSI/ASHRAE Standard 52.2-2012, Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. Atlanta: ASHRAE.

Association of Home Appliance Manufacturers (AHAM). (2009). AHAM AC-3 Method for Measuring the Performance of Portable Household Electric Room Air Cleaners Following Accelerated Particulate Loading; AHAM: Washington, DC, USA.

Association of Home Appliance Manufacturers (AHAM). (January 2013). Method of Measuring Performance of Portable Household Electric Room Air Cleaners.

Boelter, K. J., and Davidson, J. H. (1997). Ozone generation by indoor, electrostatic air cleaners. Aerosol Sci. Technol. 27, 689–708.

Center for Disease Control and Prevention (CDC). (2003). Guidelines for Environmental Infection Control in Health-Care Facilities. U.S. Department of Health and Human Services Centers for Disease Control and Prevention (CDC), Atlanta, USA.

Černecky, V., and Pivarčiová, B. (2015). Ionisation impact on the air cleaning efficiency in the interior. 2015. Measurement Sci. Rev. 15:4, 156–166.

Cheek, E., Guercio, V., Shrubsole, C., and Dimitroulopoulou, S. (September 2020). Portable air purification: Review of impacts on indoor air quality and health. Sci. Total Environ., 142585.

Daniels, S. L. (2001). Applications of air ionisation for control of VOCs and PMx. In 94th Air and Waste Management Association Annual Conference, Orlando, Florida.

Daniels, S. L. (2007). On the qualities of the air as affected by radiant energies (photocatalyt ionisation processes for remediation of indoor environments). Environ. Eng. Sci. 6:3, 329–342.

Davies, G., Bradford, N., Oliver, R., Verheul, R., and Bruce, W. W. (2018). The effects of a novel decontamination-recirculating system in reducing airborne particulate: A laboratory-based study. Orthop. Proc. 99-B.

Dreiling, J. B. (2008). An evaluation of ultraviolet germicidal irradiation (UVGI) Technology in Health Care Facilities, Kansas State University Manhattan, Kansas https://core.ac.uk/download/pdf/5164725.pdf

EN 1822: High efficiency particulate air filters (HEPA and ULPA), parts 1-5, Beuth Verlag GmbH, Berlin 1998/2001.

Eurovent 4/11. (2011). Energy efficiency classification of air filters for general ventilation purposes (1st ed.).

Foarde, K., Franke, D., Webber, T., Hanley, J., and Owen, K. (2006). Biological inactivation efficiency by HVAC in-duct ultraviolet light systems. Environmental Protection Agency.

Goodman, N., and Hughes, J. F. (2004). The effect of corona discharge on dust mite and cat allergens. J. Electrostatics, 60:1, 69–91.

Hinds, W. C. (2012). Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles. John Wiley & Sons: Hoboken, NJ, USA.

Kerins, I. (December 2018). Can an Air Purifier Remove Odors from Your Home? Air Purifier Technol. https://molekule.science/air-purifier-for-odors-in-your-home/

Kim, H. J., Han, B., Kim, Y. J., and Yoa, S. J. (2010). Characteristics of an electrostatic precipitator for submicron particles using non-metallic electrodes and collection plates. J. Aerosol. Sci. 41, 987–997.

Kim, M., Payne, W. Domanski, P., Yoon, S., and Hermes, C. (2009). Performance of a residential heat pump operating in the cooling mode with single faults imposed. App. Thermal Eng. 29, 770–778.

Kinzer, K., and Moreno, R. (1997). Performance comparison of residential in-duct air cleaning devices. Fluid Part Sep. J. 10, 233–241.

Kowalski, W. J. and Bahnfleth, W. P. (2014). MERV Filter Models for Aerobiological Applications, https://www.researchgate.net/publication/237558312

Lee, B., Bahnfleth, W., and Auer, K. (2009). Ultraviolet germicidal irradiation systems, Building Simulation 2009, Eleventh International IBPSA Conference Glasgow, Scotland, July 27–30, 2009.

Lee, B. U. (2020). Minimum sizes of respiratory particles carrying SARS-CoV-2 and the possibility of aerosol generation, nt. J. Environ. Res. Public Health, 17, 6960; doi:10.3390/ijerph17196960

Liltved, H. (2002). “Ozonation and UV-irradiation,” in Recirculating Aquaculture Systems (2nd ed.), eds. M. B.Timmons, J.M. Ebeling, F.W. Wheaton, S.T. Summerfelt, B.J. Vinci, (Cayuga Aqua Ventures, Ithaca, NY) pp. 393–426.

Liu, G., Xiao, M., Zhang, X., Gal, C., Chen, X., Liu, L., Pan, S., Wu, J., Tang, L., and Clements-Croome, D. (2017). A review of air filtration technologies for sustainable and healthy building ventilation. Sustainable Cities and Society, 32, 375–396. https://www.genano.com/infobase/comparison-between-fiber-and-electric-filtration-for-air-cleaning-in-hospital-critical-areas

McDevitt, J. J., Rudnick, S. N., and Radonovich, L. J. (2012). Aerosol susceptibility of influenza virus to UV-C light. App. Environ. Microbiol. 78:6, 1666–1669. doi: 10.1128/AEM.06960-11.

Morawska, L., Agranovski, V., Ristovski, Z., and Jamriska, M. (2002). Effect of face velocity and the nature of aerosol on the collection of submicrometer particles by electrostatic precipitator. Indoor Air, 12, 129–137.

National Air Filtration Association. (2021) Pressure Drop Considerations in Air Filtration, http://www.nafahq.org/pressure-drop-considerations-in-air-filtration/

Novoselac, A., and Siegel, J.A. (2009). Impact of placement of portable air cleaning devices in multizone residential environments. Build. Environ. 44, 2348–2356.

Noakes, C.J., P.A. Sleigh, and A. Khan. (2012). Appraising healthcare ventilation from combined infection control and energy perspectives. HVAC&R Research 18(4):658–70.

Noakes, C.J., P.A. Sleigh, and A. Khan, Gilkeson, C.A. (2012). Modeling infection risk and energy use of upper-room Ultraviolet Germicidal Irradiation systems in multi-room environments. Science and Technology for the Built Environment (2015) 21, 99–111.DOI: 10.1080/10789669.2014.983035.

Parker, D., J. Sherwin, R. Raustad, and D. Shirey, III. (1997). Impact of evaporator coil airflow in residential air-conditioning systems. ASHRAE Trans. 103:2, 395–405.

Qian, H., Li, Y., Sun, H., Nielsen, P. V., Huang, X., and Zheng, X. (2010). Particle removal efficiency of the portable HEPA air cleaner in a simulated hospital ward. Build. Sim., 3:3, 215–224.

Riley, R. L., Knight, M., and Middlebrook, G. (1976). Ultraviolet susceptibility of BCG and virulent tubercle bacilli. Am. Rev. Respir. Dis. 113:4, 413–418. doi: 10.1164/arrd.1976.113.4.413.

SAGE – Environmental and Modelling Group. (2020). Application of UV disinfection, visible light, local air filtration and fumigation technologies to microbial control.

Shaughnessy, R., Levetin, E., Blocker, J., and Sublette, K. (1994). Effectiveness of portable indoor air cleaners: Sensory testing results, Indoor Air 3, 179–188.

Shaughnessy, R., Levetin, E., Sublette, K., and Blocker, J. (1993). Effectiveness of portable indoor air cleaners in particulate and gaseous contaminant removal. In Proceedings of the 6th International Conference on Indoor Air Quality and Climate-Indoor Air, Helsinki, Finland, 4–8 July 1993.

Shaughnessy, R., and Sextro, R. (2006). What is an effective portable air cleaning device? A review. J. Occup. Environ. Hyg.3, 169–181.

Shi, B. (2012). Removal of ultrafine particles by intermediate air filters in ventilation systems: Evaluation of performance and analysis of applications. Department of Energy and Environment Chalmers University of Technology, Göteborg, Sweden.

Song, M.-J., Kang, T.-H., Han, C.-S., and Oh, M.-M. (2014). Air anions enhance lettuce growth in plant factories. Hort. Environ. Biotechnol. 55:4, 293–298.

Stephens, B., Novoselac, A., and Siegel, J. A. (2010). The effects of filtration on pressure drop and energy consumption in residential HVAC systems (RP1299). HVAC & R Res. 16:3, 273–294.

Tanaka, A., and Zhang, Y. (1996). Dust settling efficiency and electrostatic effect of a negative ionisation system. J Agr. Saf. Health, 2:1, 39–47.

United States Environmental Protection Agency (US EPA). (2002). EPA Air Pollution Control Cost Manual, (6th ed.), EPA/452/B-02-001. US EPA: Washington, DC, USA.

Violet Defense, (2017). Guide to Understanding UV Light & How It’s Redefining Clean, Vilot Defence Technology.

Ward, M., Siegel, J. A. and Corsi, R. L. (2005). The effectiveness of stand alone air cleaners for shelter-in-place. Indoor Air, 15, 127−134.

Waring, M. S., and Siegel, J. A. (2011). Indoor air quality implications of using ion generators in residences. Indoor Air, 21:3, 267–276.

Zuraimi, M., Nilsson, G., and Magee, R. (2011). Removing indoor particles using portable air cleaners: Implications for residential infection transmission. Build. Environ. 46, 2512–2519.

Zuraimi, M. S., Vuotari, M., Nilsson, G., Magee, R., Kemery, B.,and Alliston, C. (2017). Impact of dust loading on long term portable air cleaner performance, Build. Environ. 112, 261–269.

Follow us on social media accounts to stay up to date with REHVA actualities

0