Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

|

Jun ShinodaInternational Centre for Indoor Environment and Energy, Department of Environmental and Resource Engineering, Technical University of Denmark, Denmarkjunshi@dtu.dk | Ongun B. KazanciInternational Centre for Indoor Environment and Energy, Department of Environmental and Resource Engineering, Technical University of Denmark, Denmark | Shin-ichi TanabeDepartment of Architecture, Waseda University, Japan | Bjarne W. OlesenInternational Centre for Indoor Environment and Energy, Department of Environmental and Resource Engineering, Technical University of Denmark, Denmark |

Suspended radiant ceiling panels are one of the common radiant cooling solutions in buildings. One of the benefits of using radiant panels is the fact that they are prefabricated. Unlike systems that require pipes to be embedded in a concrete structure (i.e., thermally active building systems, TABS), prefabricated radiant panels can have their cooling capacity measured in a test chamber in advance. Testing and reporting procedures for radiant panels are given in standards such as EN 14240 [1] and ISO 18566-2 [2]. The latter is specifically intended for suspended panels in an open ceiling, in contrary to a closed ceiling that separates the room and the plenum spaces. According to these standards, the cooling capacity of radiant panels are measured by calculating the heat removed by the water circulation. However, when radiant panels are installed as a closed ceiling, the panels will provide cooling to both the room and the plenum. The heat extracted from the room and plenum cannot be distinguished by the cooling capacity, which is measured at the water-side. Therefore, sizing the radiant system based on the cooling capacity of the panels may result in an undersized system. The proportion of heat extracted from the room-side should be provided in addition to the cooling capacity of a panel.

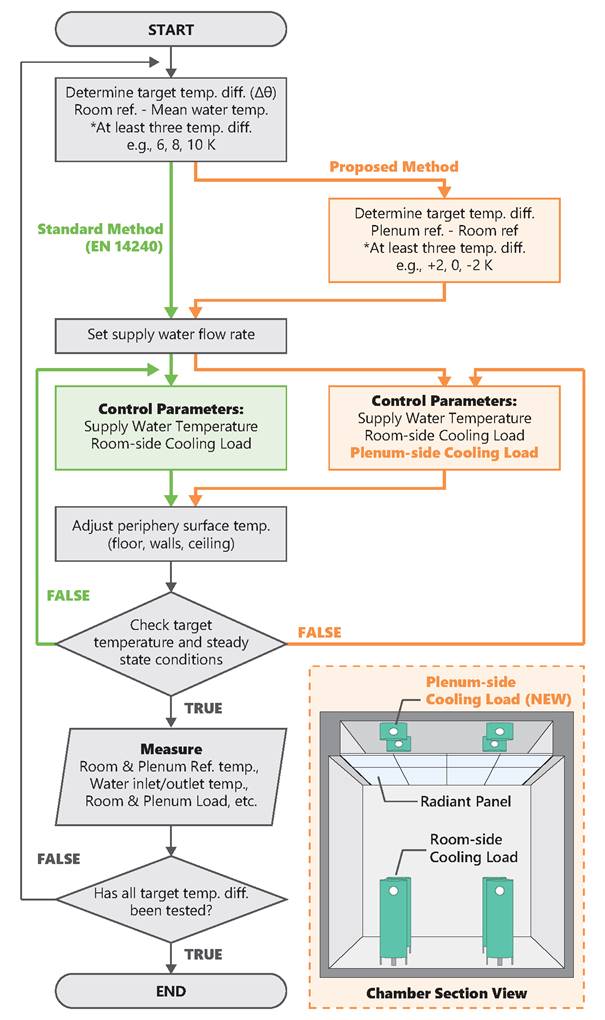

To evaluate the room-side cooling performance of suspended radiant ceiling panels, an improvement to the current measurement procedure was proposed, by taking the room and plenum temperature difference as an additional parameter [3, 4]. The proposed methodology requires cooling load simulators (heated metal cylinders) to be installed in the plenum, which will allow the plenum temperature to be controlled. Other chamber specifications were kept to be the same as those specified in EN 14240. This was intended to keep modifications to the current measurement facilities and procedure to a minimum, so that the panel manufacturers can adopt the new methodology easily. Figure 1 illustrates a detailed comparison of the conventional and proposed measurement procedures.

Figure 1. Standard and proposed cooling capacity measurement flow.

The standard procedure gives the cooling capacity (Pa, in W/m²) as a function of the difference between the room reference temperature and the mean water temperature of the circuit (Δθ). Measurements are conducted with three temperature differences to obtain a cooling capacity curve. For the standard measurement procedure, the temperature in the plenum is not controlled during these measurements. The proposed methodology in the present study repeats the three sets of measurements at three different temperature differences between the room and plenum (θplenum − θroom), corresponding to nine measurement cases in total.

Measurements following the proposed methodology were conducted in a chamber that complied with EN14240 to quantify the effects of plenum temperature on the cooling performance of suspended radiant ceiling panels and to demonstrate the applicability of the new methodology. Two panels of the same product line of the same manufacturer were selected. The two panels had the same properties except for the insulation on the plenum-side surface. One had no insulation and the other had an insulation layer (32 kg/m³ glass wool, 40 mm, 0.036 W/(m·K)). The non-insulated and insulated panels had a nominal cooling capacity (cooling capacity at Δθ = 8 K) of 61 W/m² and 58 W/m², respectively. The insulated panel had a lower nominal cooling capacity because the plenum temperature was not controlled during the measurement and had less heat extraction from the plenum. A full set of measurements (9 cases) was conducted for the non-insulated panels, and three cases were conducted for the insulated panels.

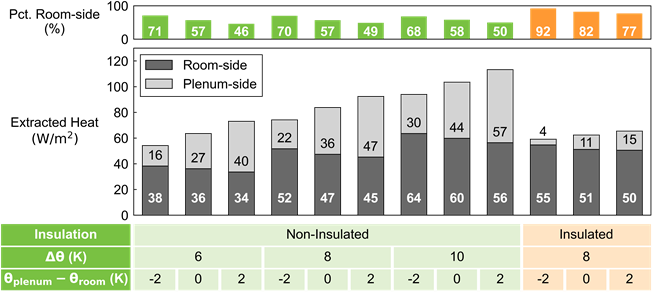

Figure 2 shows the heat extracted from the room and plenum. The sum of the heat extracted from both spaces is the cooling capacity of the panel. The results show that an increase in the plenum temperature resulted in an increase in the cooling capacity and the plenum-side heat extraction, while decreasing the room-side heat extraction. When the plenum temperature was higher than the room temperature, more than half of the cooling capacity was dedicated to the cooling of the plenum-side. The percentage of room-side cooling to the cooling capacity ranged between 77 and 92% for insulated panels, while it was between 46 and 71% when panels were not insulated. Insulation is an effective way to increase the percentage of room-side cooling, but up to approximately 20% of the cooling was from the plenum under the tested conditions, even with insulation. High plenum temperatures can be expected in cases such as when the panels are installed on the top floor where the ceiling slab is exposed to solar radiation or on any floors where waste heat from lighting armatures may be present. In such situations, attention must be given to the plenum temperature and the resulting plenum-side heat extraction of the panels.

Figure 2. Heat extraction from the room and plenum by the non-insulated and the insulated panels.

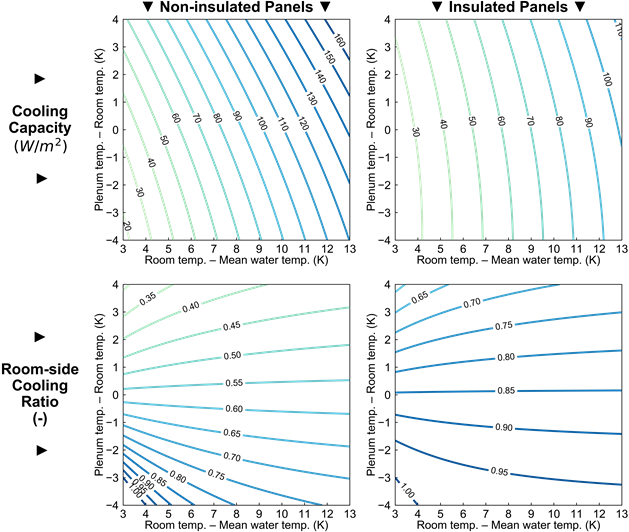

Based on the measurement data shown in Figure 2, an empirical prediction model to predict the cooling capacity and room-side cooling ratio of a specific panel was developed, as illustrated in Figure 3. The prediction model is specific to each panel, and can be developed based on measurement data obtained according to Figure 1. The detailed method and equations are presented in [3]. The difference between the room and mean water temperature (Δθ) and the temperature difference between the room and plenum (θplenum − θroom) are used as inputs to the model. For example, assuming Δθ = 8 K and θplenum − θroom = −2 K (plenum temperature 2 K lower than room temperature), the total cooling capacity for the non-insulated would be 76 W/m², and the room-side cooling ratio would be 68%. This corresponds to 52 W/m² of cooling at the room-side. With the same temperature conditions, the insulated panels would yield a cooling capacity of 60 W/m², of which 56 W/m² would be dedicated to the room-side. This example shows that the proposed methodology can give a clearer guidance on the cooling performance of the radiant panels in a given temperature condition.

Figure 3. Developed prediction model for the tested panels.

To validate the developed model, we conducted field measurements in an office building that was equipped with the same non-insulated panels tested in the chamber measurements. The case study building was a 32-floor, high-rise office building situated in the Greater Tokyo Area of Japan. The office floor had dimensions of 56.4 × 56.4 m, with a large open plan layout along the north, west, and south sides. The ceiling and plenum heights were 2.8 m and 1.08 m, respectively, and radiant panels covered 58% of the ceiling. Measurements were conducted on the 24th floor for one week during August 2020. Heat flux sensors were installed to measure the room- and plenum-side heat flux of a selected radiant panel. The room and plenum temperatures of the office area and the supply and return temperatures of the panel circuit were measured to obtain the input values necessary for the prediction model.

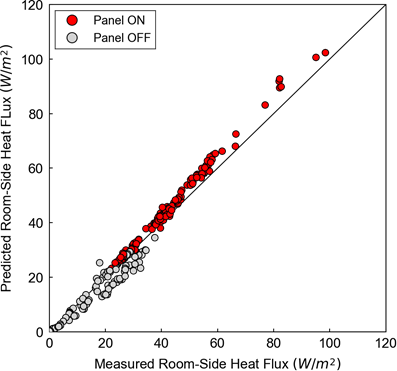

Figure 4 shows the comparison of the measured and predicted room-side heat flux (cooling). The model shown in Figure 3 was used for the prediction, with the measured values as inputs. During the whole measurement period, the plenum temperature was within ±2 K of the room temperature, which was the temperature range tested in the chamber. The percentage of room-side cooling was mostly within the range of 65–70% when the panels were operating. The measured and predicted values were in good agreement, with an average error of 6% with a standard deviation of 3%.

Figure 4. Comparison of measured and predicted heat flux.

Test chamber measurements showed that the plenum temperature, in relation to the room temperature, has a large influence on the cooling performance of suspended radiant ceiling panels. Regardless of any insulation of the panels, the plenum temperature must be considered, especially if high temperatures in the plenum are expected. The current cooling capacity measurement method cannot fully document the cooling performance of suspended radiant ceiling panels i.e., how much heat is removed from the room and plenum. An improvement to the measurement and reporting method, with minimal changes to the current measurement facilities, was therefore proposed. The newly proposed method enables the distinction between the total heat extracted from the panels and the heat extracted from the room-side. This would allow more accurate sizing of the panels and an improved operation and control of them. It is recommended that standards applicable to closed-type suspended radiant ceiling panels (such as EN 14240) incorporate plenum temperature control in their measurement procedure, as described in the present study.

[1] EN14240: Ventilation for Buildings - Chilled Ceilings - Testing and Rating, European Committee for Standardization, 2004.

[2] ISO18566-2: Building Environment Design - Design, Test Methods and Control of Hydronic Radiant Heating and Cooling Panel Systems - Part 2: Determination of Heating and Cooling Capacity of Ceiling Mounted Radiant Panels, International Organization for Standardization, 2017.

[3] Shinoda, J., Kazanci, O. B., Hidari, K., Watanabe, H., Takahashi, Y., & Tanabe, S. (2022). Improvements to the cooling capacity measurements of suspended radiant ceiling panels to prevent under-sizing. Journal of Building Engineering, 51, [104242]. https://doi.org/10.1016/j.jobe.2022.104242.

[4] Shinoda, J., Kazanci, O. B., Tanabe, S., Hidari, K., Watanabe, H., & Takahashi, Y. (2022). Room-side and Plenum-side Cooling Prediction of Suspended Radiant Ceiling Panels. CLIMA 2022 Conference. https://doi.org/10.34641/clima.2022.137.

Follow us on social media accounts to stay up to date with REHVA actualities

0