Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

Tiziana Buso | Martin Vahi |

Enerbrain*corresponding author - email address: t.buso@enerbrain.com | Enerbrain Nordics |

|

|

Stephanie Aumann | Jacopo Toniolo |

Enerbrain | Enerbrain, Politecnico di Torino |

The article presents the energy saving achieved thanks to the implementation of a retrofit measure applied to the Building Management System of an Estonian shopping mall. The retrofit project upgraded the HVAC-related BMS control features by exploiting IoT and ICT technologies and cloud-based machine learning algorithms. The application resulted in energy savings up to 45% with respect to heating and ventilation energy use of the whole building.

In September 2020 the European Commission proposed to raise the 2030 greenhouse gas emission reduction target to at least 55% compared to 1990, as a stepping stone to the 2050 climate neutrality goal. To achieve this result, the EU should reduce buildings’ greenhouse gas emissions by 60% (European Commission, 2020). Considering that at present roughly 97% of the EU’s building stock is not energy efficient, and that only approx. 1% of the existing buildings is renovated each year (BPIE, 2020), the implementation of energy efficient retrofit measures for buildings has to accelerate significantly in the next decade.

With “energy efficiency first” and “affordability” among the guiding principles for this much longed Renovation Wave, advanced Building Automation and Control Systems (BACS) can play a major role in scoring the goal, as they can generate energy savings with rather low investment and installation burden (eu.bac, 2019).

The official definition of BACS is given by the European Standard EN 15232-1:2017 (CEN, 2017). The standard provides classification for these systems according to their energy efficiency from class D, not efficient, to class A, high performing, and quantifies the energy saving potential of high efficiency BACS (savings up to 96%). EN 15232-1 also defines the minimum functions that make high efficiency BACS capable of reaching the estimated savings: it requires the Technical Building Systems to be managed based on the monitored building status and predicted needs, optimizing occupants’ comfort, maintenance and energy use. As concluded by the EPBD (European Parliament, 2018), these requirements will become mandatory for non-residential buildings with rated output for heating and ventilation of >290 kW, i.e. for the majority of the non-residential building stock, as of January 1st 2025.

The increasing implementation of Internet of Things (IoT) and Information and Communication Technologies (ICT) in buildings, which support an easier availability of a huge amount of building-related data, can hasten the adoption and further increase the impact of BACS for optimizing the energy performance of the building stock, leveraging the great opportunities provided by the current advances in applied Artificial Intelligence (AI) (Brandi et al., 2020).

This article aims at providing evidence of the energy saving potential of high performing, AI-powered BACS for the control of the Heating, Ventilation and Air Conditioning system of a tertiary building. Specifically, the following sections describe the solution implemented and the energy savings achieved in an Estonian shopping mall thanks to the implementation of the Enerbrain System - a cloud-based solution for the control of existing HVAC systems using IoT technologies and Machine Learning algorithms.

The subject of this article is a three-floor, 30 000 m² shopping mall in Narva (Estonia), hosting over 50 commercial activities including a supermarket, a cinema and bowling facilities. The mall is open to the public from Monday to Sunday from 8:00 to 24:00, with opening hours varying from activity to activity.

Heat is supplied to the building by the municipality district heating, while chilled water is provided by three air cooled chillers. The main components of the HVAC system are five Full Air Handling Units, whose details are listed in Table 1.

Table 1. Features of the main HVAC components of the shopping mall.

Building Area | HVAC component | ||||||

Name | Year of installation | Heating Coil | Cooling coil | Supply Fan | Extract Fan | Other features | |

Power [kW] | Power [kW] | Air flow [m³/h] | Air flow [m³/h] | ||||

Shops area | AHU 1 | 2006 | 414.2 kW | 340 kW | 80 280 | 73 440 | _VFD _Recirculation damper _Rotary heat exchanger |

Cinema | AHU 2 | 2006 | 97 kW | 61.4 kW | 14 163 | 12 838 | _VFD _Rotary heat exchanger |

Shopping Center | AHU 3 | 2013 | 589.7 kW | 374.5 kW | 79 200 | 79 200 | _VFD _Recirculation damper _Rotary heat exchanger |

Supermarket | AHU 4 | 2013 | 62.56 kW (1) 160.68 kW (2) | 118.7 kW | 22 320 | 19 080 | _VFD _Recirculation damper _Rotary heat exchanger |

Shopping Center | AHU 5 | 2013 | 432.9 kW | 319.1 kW | 75 600 | 75 600 | _VFD _Recirculation damper _Rotary heat exchanger |

The HVAC system is controlled by a Building Management System (BMS) and some independent local controllers, set up to maintain the desired indoor environmental conditions, listed below:

· Heating set-point: 22°C (heating season: October–May)

· Cooling set-point: 25°C (cooling season: June–September)

· Relative Humidity acceptability range: 30–50%

· CO₂ level acceptability threshold: 1 000 ppm

The mall’s typical annual HVAC-related energy consumptions total to approximately 3 000 MWh of district heating and 1 700 MWh of electricity.

The goal of the building owner was to improve the energy efficiency of the HVAC system, thus reducing the related operational expenditures, without compromising occupants’ comfort and with no major modifications to the existing set-up.

The solution implemented to meet the stakeholders’ expectations is made up of IoT sensors, metering devices and controllers, and cloud-based adaptive and predictive algorithms.

To avoid any changes to the installed components or to the existing BMS infrastructure, a “Man in the Middle” approach was proposed, i.e. the provision of a new control system to be positioned between the existing control system (the BMS) and the physical component steered by it.

Specifically, in “Man in the Middle” applications of the Enerbrain solution, IoT controllers are installed to act on selected actuators/controllers of the already in place HVAC system (e.g. to modulate fans speed by controlling VFD (Variable Frequency Drive) - see Figure 1. These actions on HVAC components are dictated by commands elaborated by the Enerbrain algorithm, that uses as inputs for its commands the desired settings for the building (e.g. temperature set-points and schedules), a number of external variables gathered in cloud (e.g. weather data) and the real-time conditions (e.g. indoor temperatures, CO₂, fluid temperatures) monitored by newly installed IoT wireless sensors.

Figure 1. IoT controllers controlling the VFDs of supply and extract fans of AHU 1.

Table 2 details the HVAC components and actuators object of the Enerbrain intervention in the shopping mall.

Table 2. The Enerbrain “Man in the Middle” solution implemented.

Building Area | HVAC component | Actuators/controllers under Enerbrain control | Indoor parameters monitored by Enerbrain |

Shops area | AHU 1 | Heating coil valve Cooling coil valve Supply fan VFD Return fan VFD | Air temperature Relative Humidity CO₂ concentration |

Cinema | AHU 2 | Heating coil valve Cooling coil valve Supply fan VFD Return fan VFD | Air temperature Relative Humidity CO₂ concentration |

Shopping Center | AHU 3 | Heating coil valve Cooling coil valve Supply fan VFD Return fan VFD | Air temperature Relative Humidity CO₂ concentration |

Supermarket | AHU 4 | Pre-Heating coil valve Cooling coil valve Post-Heating coil valve | Air temperature Relative Humidity CO₂ concentration |

Shopping Center | AHU 5 | Heating coil valve Cooling coil valve Supply fan VFD Return fan VFD | Air temperature Relative Humidity CO₂ concentration |

Note that for each HVAC component under consideration, the signal from/to the existing control system is maintained, and overwritten by Enerbrain control only when the Enerbrain System is active.

Additionally, monitoring devices were installed to provide sound evidence of the energy savings generated thanks to the optimized control of the above listed AHUs’ (Air Handling Units) components:

· electricity monitoring devices able to measure the power of individual circuits were installed for the five AHUs (fans electricity use) and for the three chillers;

· daily readings of the building District Heating meter were gathered by installing a remotized digital camera.

To offer accurate projections of the energy savings achievable thanks to the optimized control of the five Air Handling Units, Proof of Concept (POC) periods were scheduled before the official activation of the new advanced control system. The winter POC period lasted from October 2019 to February 2020, the summer POC from May to June 2020.

The two POCs took place in "ON/OFF" mode, alternating weeks OFF to weeks ON. Indeed, thanks to the Enerbrain “Man in the Middle” technical approach, the new system can be easily activated (Enerbrain ON) and deactivated (Enerbrain OFF) via a web application. In OFF periods the HVAC system was managed according to the existing control logics (e.g. by the BMS commands); in ON periods, the HVAC system was managed according to Enerbrain control logics (i.e. by the adaptive and predictive algorithms).

By applying the proper calculation method, the energy consumption in OFF periods can be compared to the energy consumption in ON periods, thus providing reliable results of the energy saving potential.

The savings calculation method used in this article is compliant with the guidelines given by the International Performance Measurement and Verification Protocol (IPMVP). The method involves the identification of a calculation-based energy model that describes the normal behaviour of a building's energy consumption, which can then be used as a baseline for comparison with the consumption measured after the implementation of an Energy Conservation Measure - in our case the installation of an advanced BACS. The savings, or rather, the "avoided consumption", is determined by the difference between the post-intervention measured consumption and the baseline energy model adjusted according to the variables.

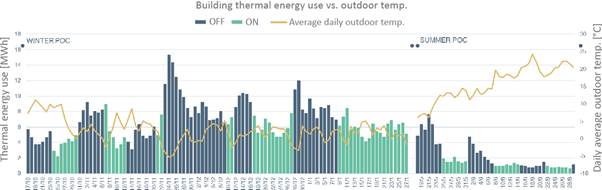

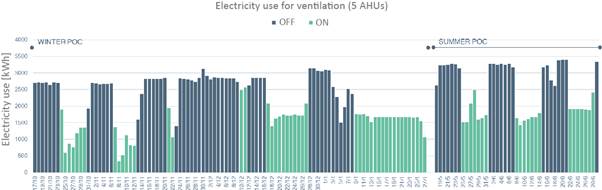

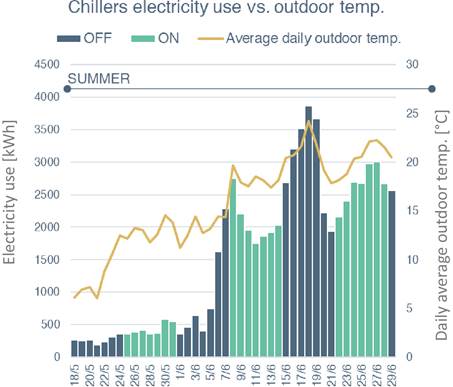

Figure 2, 3 and 4 display the recorded energy consumptions in Enerbrain OFF and ON periods for the whole building heating energy use, for the five AHUs and for the three chillers respectively.

Figure 2. Recorded daily District Heating energy use of the whole building during Winter and Summer POCs.

Figure 3. Recorded daily electricity use of the AHUs during Winter and Summer POCs.

Figure 4. Recorded daily electricity use of the chillers during the Summer POC.

In line with IPMVP prescriptions, the following approaches were applied to build the baseline energy models:

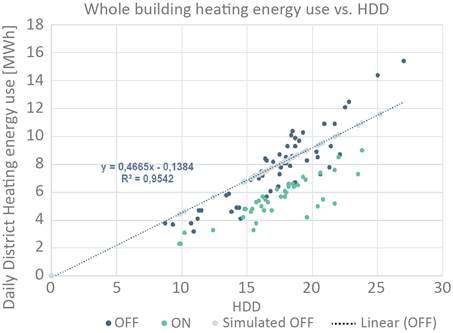

· District Heating (DH) energy use: linear regression equation using HDD20 as independent variable. The regression model is built by plotting the daily DH energy use monitored in days OFF with the corresponding HDD20, derived from the nearest weather station (Weather station ID 26058, Narva. Data source: www.degreedays.net). Figure 5 displays the plotted data and the resulting linear regression equation describing the baseline District Heating energy use, i.e. the energy use without Enerbrain control in place.

· AHUs energy use: daily average consumption. No normalization factor applied because of the constant energy use profile detected.

Figure 5. Daily DH energy use versus HDD, and linear regression equation resulting from the plotted data in OFF days.

Chiller’s energy use: linear regression equation using outdoor temperature as independent variable. The regression line is built by plotting the daily electricity use of chillers monitored in days OFF with the corresponding daily average temperature, derived from the nearest weather station.

For each energy use, the energy savings were calculated by comparing baseline energy use calculated for the days of Enerbrain ON with the actual energy use monitored in those days. The resulting figures are summarized in Table 3.

Table 3. Calculated energy savings during Winter and Summer POCs.

Energy vector | Energy use | Energy savings | |

Winter POC | Summer POC | ||

District Heating | Heating | 29% | 45% |

Electricity | Ventilation (5 AHUs) | 45% | 43% |

Cooling | - | 6% | |

These results are in line with the energy efficiency projections provided in EN 15232-1:2017, which estimates that in wholesale buildings a high performing BACS can improve the overall energy performance of up to 40% with respect to a standard BACS.

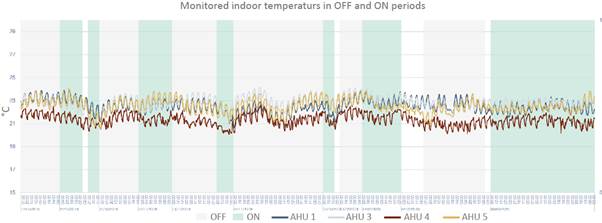

The installation of IoT environmental sensors in all the areas served by the controlled AHUs allowed building managers to verify if the achieved energy savings jeopardised the indoor comfort conditions. Figure 6, by displaying the hourly average temperatures recorded for each area for the whole POC duration, gives evidence that similar comfort conditions were maintained in OFF and ON periods.

Figure 6. Hourly average indoor temperatures monitored in the areas served by the controlled AHUs.

This article describes the implementation of a solution to upgrade the BMS control features in a shopping mall, making it possible to have the features of an advanced BACS. Indeed, by exploiting IoT and ICT technologies and AI, the proposed solution offers the opportunity to continuously analyse the real-time conditions of the HVAC system and to modify control settings accordingly.

This retrofit measure, implemented to steer only selected components of the HVAC system via a non-invasive installation, resulted in energy savings up to 45% with respect to heating and ventilation energy use of the whole building, with no consequences on the indoor environmental quality levels.

Such results provide further evidence of the crucial role of building controls systems in supporting the transition toward an energy efficient building stock, able to meet both the long term EU carbon neutrality expectations as well as the short term building owners’ financial KPIs.

European Commission (2020). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A Renovation Wave for Europe - greening our buildings, creating jobs, improving lives, 14 October 2020, COM(2020) 662 final, Brussels.

BPIE (2020). On the way to a climate-neutral Europe – Contributions from the building sector to a strengthened 2030 climate target. Brussels: Buildings Performance Institute Europe (BPIE).

European Parliament (2018). Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 amending Directive 2010/31/EU on the energy performance of buildings and Directive 2012/27/EU on energy efficiency, Brussels.

eu.bac (2019). Guidelines for the transposition of the new Energy Performance Buildings Directive (EU) 2018/844 in Member States. European Building Automation Controls Association (eu.bac).

CEN (2017). Energy Performance of Buildings - Energy performance of buildings - Part 1: Impact of Building Automation, Controls and Building Management - Modules M10-4,5,6,7,8,9,10, EN 15232-1:2017. https://epb.center/documents/en-15232-1/.

Brandi S., Piscitelli M., Martellacci M., Capozzoli A.(2020). Deep reinforcement learning to optimise indoor temperature control and heating energy consumption in buildings, Energy & Buildings 224 (2020) 110225.

Follow us on social media accounts to stay up to date with REHVA actualities

0