Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

|

Ralf GritzkiInstitute of Power Engineering, TU Dresden, 01062 Dresden, Germany | Jens NaumannRettig ICC Crimmitschau, Germany | Claudia KandziaInstitute of Power Engineering, TU Dresden, 01062 Dresden, Germany | Clemens FelsmannInstitute of Power Engineering, TU Dresden, 01062 Dresden, Germany |

This

article deals with the comparison of the heating-up times of four different

floor heating systems: a standard wet system and three renovation systems with

lower installation height. The renovation systems are the wet system K and two

dry systems C and T. The dry-system T is characterized by a special heat

conduction plate and the system C by the absence of an insulation layer. By

using a transient coupled CFD simulation, the processes of heat conduction,

heat radiation as well as the convective heat transport due to the air- and

water flows are calculated.

The four

systems show a different dynamic of the heating-up times. Table 1

gives an overview about the layers of the four systems.

Table 1. Layer of the floor heating systems

from top down.

Wet system | Wet system | Dry system | Dry system |

Tiles, 10 mm | Tiles, 10 mm | Tiles, 10 mm | Tiles, 10 mm |

Heating screed, 65 mm Heating pipe, 17x2 mm | Heating screed, 21 mm Heating pipe, 16x2 mm | Load distribution, 5 mm, λ = 0.2 W/(mK) Heat conduction plate, aluminium, 0.25 mm heating pipe, 14x2 mm | Heating screed, 21 mm Heating pipe, 10x1 mm |

Insulation material, 30 mm, λ = 0.04 W/(mK) | Insulation material, 6 mm, λ = 0.04 W/(mK) | Insulation material, 17 mm, λ = 0.04 W/(mK) | No insolation material |

Screed 45 mm | Screed 45 mm | Screed 45 mm | Screed 45 mm |

|

|

|

|

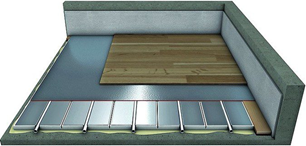

Figure 1 shows the layer of the floor

heating system by the example of the T dry system. One can see very well, how

the heating pipes are surrounded by the heat conduction plates. This heat

conduction plates with a thickness of 0.25 mm are modelled fully three dimensional

in the simulation model.

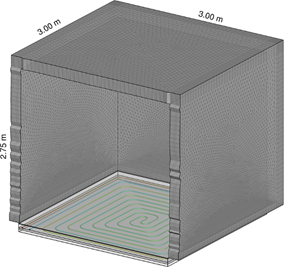

The four

different systems are simulated in a test cabin made of 200 mm thick

aerated concrete walls with a base area of 3 m x 3 m and an

interior height of 2.75 m without openings, see Figure 2. Related to the floor area of 9 m2 a laying distance

between the pipes of 150 mm leads to a pipe length of about 57.7 m

and a laying distance of 125 mm results in a pipe length of 69.2 m.

Figure 1. floor heating system T with heat conduction plates; reference: www.bba-online.de.

Figure 2. Geometry of the test cabin and

meshing of the wall layers and laying patterns of the floor heating.

Transient,

coupled simulations of the test cabin, underfloor heating system, water flow

and room air flow are done for all four systems. For the evaluation, the

surface temperatures and their local distribution as well as the water

temperatures are evaluated in detail as a step response when switching on the

underfloor heating system. Furthermore, the enthalpy flows between the water

inlet and outlet and the (convective and radiative) heat flows from the floor

are evaluated.

The

numerical model considers the following aspects:

·

three-dimensional

non-isothermal water flow inside the pipes

·

three-dimensional

thermal conduction within the inner walls of the pipes as well as within all

other layers in the respective floor structure

·

three-dimensional

heat conduction within the side walls of aerated concrete

·

non-isothermal

turbulent simulation of the air flow in the test cabin taking

into account the radiation heat exchange within the test cabin

The initial

condition is a uniform temperature of all zones of 15 °C at the start time

and a constant fluid in the test cabin as well as in the floor heating tube.

For the

water inlet the mass flow rate into the heating pipes is set to 0.025 kg/s

with a supply temperature of 35 °C. There is no heat loss assumed below

the lower screed layer and on all sides of the floor structure. The

calculations are done over a period of six hours of simulated real time. This

period is chosen to ensure that in each of the four systems the desired mean

surface temperature of the floor area of 24 °C is reached. The calculated

flow velocities are less than 0.1 m/s in the tubes.

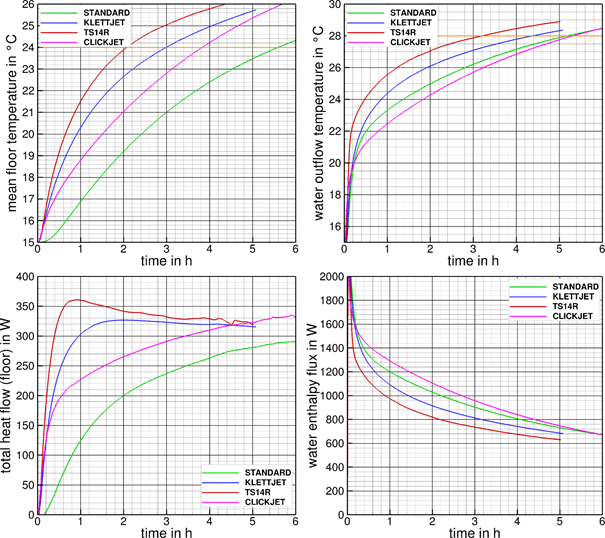

Figure 3. Step responses; from top left to bottom right: time profile of medium surface temperatures of the floor, time profile

of mean return temperatures of the water, time profile of total heat flows of

the floor, time profile of resulting enthalpy fluxes of the water; in each case

for all four systems.

Figure 3, on the left in the upper part,

shows the mean surface temperature profiles of the four different systems. The

right side represents the corresponding profiles of the water return

temperatures. In addition, the total thermal heat flows (convection and

radiation) emitted by the respective floor as well as the resulting enthalpy

fluxes transferred from the water to the respective floor structure are shown

in the diagrams in the lower part of Figure 3.

The

different dynamics of all four investigated systems can be clearly seen from

the diagrams. Due to the much larger thermal mass of the heating screed, the STANDARD

system has the biggest inertia, which results in a slower heating of the tiles

and thus also a slower increase in the heat dissipation of the floor heating as

a whole. The K system is more dynamic than C due to its insulating layer

preventing heat to be transferred into the building structure rather than to

the room. Due to the insulating layer, the heat flow into the screed below it

is significantly lower than in the C-system. This is also shown by the overall

higher enthalpy flux which C-system’s water gives to the surrounding floor

layers (see Figure 3, bottom right). In this case,

however, a higher heat flow through the tube walls occurs due to the smaller

internal diameter of the tube and the associated higher velocity of the water.

The good thermal insulation downwards as well as the very good heat distribution

upwards over the heat conducting plates lead to a very high dynamic in the

system T. The required average floor temperature is reached three times faster

than with the system STANDARD. The T-system has been identified as a fast

reacting underfloor heating system where the highest overall heat output of the

floor is observed with the lowest enthalpy flux of the water during the heating

phase. The energy transfer from the water to the chamber is therefore the

fastest in this system.

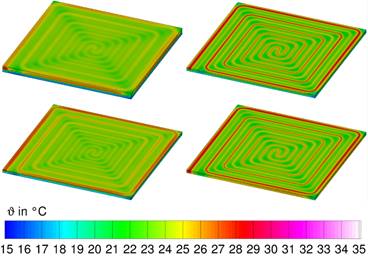

The

described facts can also be found in the representation of the temperature

distributions of the different configurations, see Figure 4. If more energy has to be distributed in the floor, the system becomes

slower.

Figure 4. Surface temperatures of the whole

underfloor heating system, after reaching a mean surface temperature of

24 °C, view from above; from top left to bottom

right: the STANDARD-system and the systems K, T, C.

If a

parquet floor is modelled instead of the floor tiles, all systems react much

slower due to the lower heat conduction of the wood layer. The differences

between the floor heating systems analysed are smaller. However, this wooden

surface layer leads to an equalization of the surface temperatures. The ripple

of the temperature profiles is significantly lower in all four systems than in

the case of the floor construction with tiles.

Follow us on social media accounts to stay up to date with REHVA actualities

0