Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

|

Jana Lendelová | Ingrid Karandušovská | Miroslav Žitňák | Milada Balková |

Institut of Agricultural Engineering, Faculty of Engineering Slovak University of Agriculture in Nitra, Slovakia | Institut of Agricultural Engineering, Faculty of Engineering Slovak University of Agriculture in Nitra, Slovakia | Institut of Agricultural Engineering, Faculty of Engineering Slovak University of Agriculture in Nitra, Slovakia | Institut of Agricultural Engineering, Faculty of Engineering Slovak University of Agriculture in Nitra, Slovakia |

Dairy cow farming is one of the largest sources of NH₃and CH₄within livestock production (Poteko, 2019). Their high concentration in production buildings has a negative effect on both livestock and livestock breeders. Poor ventilation can increase the relative humidity and the concentration of harmful gases such as carbon dioxide and ammonia. The concentration of carbon dioxide depends to a large extent on the type of building, the ventilation system and the density of the animals. A significant source of CH₄is the manure because it contains cellulose that is degraded by methane-producing bacteria (Maurer et al., 2016). Ammonia contributes to eutrophication and soil acidification, and it exerts an adverse impact on biodiversity and ecosystems (Witkowska & Sowińska, 2017). Many factors influence the concentrations of harmful gases, in especially high temperature, emitting area and emission source, etc. Due to climate change, even in temperate climates, the issue of high air temperatures and increased heat load is increasingly becoming more common and affects high producing dairy cows the most (Herbut, 2019). One option to reduce heat load in dairy cows and increase air quality is by using flow cooling through natural and forced ventilation. Natural ventilation is dependent on weather and structural design and is often not adequate in summer. Then it is required to provide cooling by forced ventilation or by a combination of several methods (evaporative cooling, shading, spraying of animals, etc.) (Fournel, 2017). To assess the quality of the environment, in scientific practice, combined methods are used - part of practical measurements and part of theoretical calculations, or the detection of production or health indicators. The worst combination is when extremes in both high concentration of pollutants and high heat load of animals occur. The article is devoted to the comparison of the state of air chemistry and the level of heat load in two structurally different types of barns.

The research was performed during the summer season in two types of dairy cattle barns, in the same farm. The barns differed in herd size, housing system, and manure management.

The new PUR panel-hall building “A” for 444 dairy cows had two internal feeding corridors, the length of the building was 85.4 m, the width of the building was 51.8 m. The total height of the 3-sector counter roof in the ridge was 18.2 m. The steel structure system with 4 longitudinal rows of columns was made in a module of 5 m. The height of the wall was hs=8 m on the south side, hn=7 m on the north side. The front walls were made of PUR-panels with a thickness of 40 mm, 8 gates for the entry of the mechanisms were made up of remote-controlled green plastic blinds. The roller shutter system was also used on the side walls, where a fully openable roller shutter 85 m long and 4.8 m high was made above the 2.2 m high fixed wall. The roof area was composed of three roof boards - the southern area made of PUR-panels 1,500 m² (with slope of 15°), the middle area made of double-cavity polycarbonate corrugated roofing 1,865 m² with a slope of 15° and the northern roof (PUR-panel) area 1,440 m² with a slope of 24°. Two large vertical slits were made along the entire roof, which ensure the removal of air through natural ventilation. The upper continuous intermediate vertical opening in the ridge was 3.3 m high, the second vertical roof opening was high of 1.5 m.

The dimensions of massive old brick building “B” for 158 dairy cattle were 70 m in length and 11.5 m in width. The height of the side (longitudinal) wall was 4.3 m and a ridge height was 9.7 m. An outdoor feeding area with a length of 70 m and a width of 3.25 m was added to the building. The ceiling parts were removed due to the increase in the volume of the building from the original 2,329.6 m³ to 5,154.1 m³. The ridge of the roof was opened to a width of 350 mm and parts of the roof covering were illuminated by five vertical strips 1 m wide. In the old building, there was an air volume of 34.3 m³ per animal, a floor area of 4.85 m² per animal indoors and 6.37 m² per animal including the outdoor covered feeding area. Five basket fans were installed in the longitudinal axis above the double cubicles, each with a capacity of 16,500 m³h-1 (total 82,500 m³h-1).

The concentrations of CH4, NH3, N2O, and CO2were measured using a photo-acoustic multi-gas analyser 1309 (Inova, Denmark). Gas concentrations were measured at 4 indoor locations in the object A and 4 indoor locations in the object B and 1 outdoor location. Air was sampled from the various locations using 10–30 m long polytetrafluoroethylene (PTFE) tubes with an inner diameter of 3.2 mm. The air temperature and relative humidity were measured every 5 min using datalogger Comet. The two types of indexes were used to evaluate the heat load of animals. The temperature humidity index (THI) combines the air temperature and relative humidity into one value to estimate the heat load. We assessed heat stress according to the levels set as follows: mild heat stress 72 < THI < 79, moderate stress 80 < THI < 89 and severe heat stress THI > 89 (Armstrong, 1994; Hoffmann et al., 2019). The Equivalent Temperature Index for dairy Cattle (ETIC - calculated according to Wang et al., 2018) takes into account - in addition to temperature and relative air humidity - air velocity and solar radiation (Hempel et al. 2019). We valuated ETIC according 4 categories: mild category 18 ≤ ETIC < 20, moderate category 20 ≤ ETIC < 25, severe category 25 ≤ ETIC < 31, emergency category 31 ≤ ETIC (Hempel et al. 2019). The quality of the workers' working environment was evaluated according to Law No 355/2007 and DECREE No 99/2016.

The aim of this study was to compare the concentrations of harmful gases and microclimatic properties of indoor air in two different building and benefits of construction types of dairy housing in the summer season with an emphasis on the evaluation of the effect of structural innovation on air chemistry and animal heat load indexes, as well as parameters of the quality of the employees' environment.

Data on climatic parameters, gas concentrations in two barns with different housing systems were processed statistically. Since all variables had a normal distribution, single factor ANOVA was performed. The significance of differences between the mean values of gas concentrations in barns was determined by Tukey’s test. All calculations were made using Statistica 10 for Windows (StatSoft, CZ).

During the assessment of indoor climate parameters, no significant differences were found between objects A and B (p > 0.05), however, the pre-ventilation fans were not operating in building A during the research as per the methodology. The intention of the breeder was to provide the new building with a large-cubicle space with low-energy, quiet and low-emission operation.

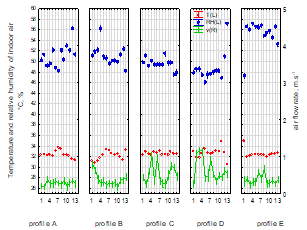

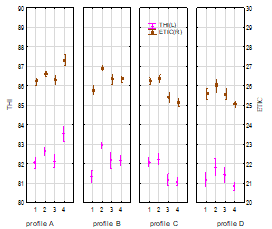

The optimum temperature in dairy cow housing is 8–16°C (Kołacz and Dobrzański, 2019). As aspected - in neither building was the optimal temperature ensured. In the location of Central Europe, this is almost impossible during the day in summer. Moreover, the methodology of the experiment was aimed at monitoring situations during days with extremely high outdoor air temperatures, so that air chemistry and heat load were assessed for critical cases. The climatic data were recorded during the period with outdoor air temperature 30°C < Text < 32°C, relative humidity 47% < RHext < 53% and airflow velocity 0.2 m.s-1 < vext < 1.2 m.s-1. The average values from climatic measurements at 65 indoor points in the building A without the use of motor ventilation were: Tint,AVG=32,61±0,71°C, RHint,AVG=50,94±2,86%, vint,AVG=0,47±0,28m.s-1. According the two heat indexes were not found a significant differences in that values; the THIA,AVG=82.09±0.89 and ETICA,AVG=26.12±0.71 (Figure 1). Heat stress level was not significantly different (P > 0,05) compared these two buildings - it was moderate (for THI) and severe (for ETIC) cathegory, but there were different possibilities to modify this level. For old one - very limited possibilities, for new one there were a lot of technical solutions.

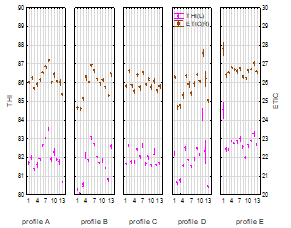

According to results of the evaluation of on-farm climatic measurements at the 16 indoor points in the building B using motor ventilation we found, that the average values were: Tint,AVG=32,22±0,45°C, RHint,AVG=52,92±2,14%, vint,AVG=0,37±0,23m.s-1. The Temperature-Humidity Index was higher that limit level with value of THIB,AVG=81.93±0.87 and Equivalent Temperature index for Dairy Cow was ETICB,AVG=26.07±0.71, which is about the limit level (Figure 2).

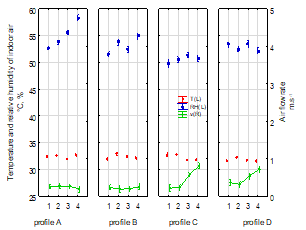

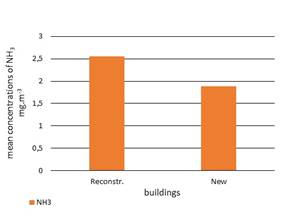

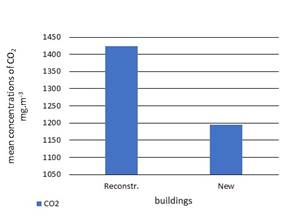

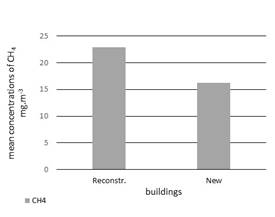

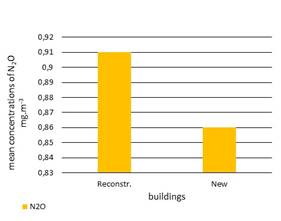

Mean concentrations of greenhouse gases and ammonia differed significantly (P < 0.01) between facilities. Building A (new) was characterized by lower (P < 0.01) mean concentrations of GHGs and ammonia compared to building B (Figure 3). The detected amounts of all gases were lower than the recommended environmental limits for workers and animals during the experiment.

The average CO2concentration in the new barn (A) was 9.8% lower than in barn B. The most significant improvement in view of chemistry was observed for NH3, which was 34.2% lower in the new facility, and CH4concentrations were 41.5% lower than in the old facility.

Figure 1. Results of microclimate conditions in low-volume new barn A.

Microclimatic parameters are an important physical factor of the working environment, which in Slovakia is subject to Act No. 355/2007 and decree no. 99/2016 Coll.

For working class “1b”, the optimum temperature is Top=22–25°C, permissible relative humidity RH=30–70% and permissible air velocity v ≤ 0.3 m.s-1.

A new structural barn design and innovative housing technology have increased the comfort of the housed animals and the air quality in terms of ammonia production, greenhouse gases as well as microclimatic parameters which are also supported by the findings of other researchers (Witkowska, 2017; Dimov et al. (2019). The productivity of labour has also increased, the cubic volume of the environment has increased from the original VB=34.3m³ to the new VA=82.5 m³ per cow.

Figure 2. Results of microclimate conditions in large-volume old - reconstructed barn B.

Figure 3. Results of mean concentrations of ammonia and greenhouse gases measured in reconstructed and new barn.

The design of ventilation openings in buildings with natural ventilation is also an important element subject to beneficial innovative changes Li et al. (2020). In accordance with his testing, the design of the side walls of barn A of our experimental farm stands out, where the wall openings occupied the area (ARw), protected by a controllable roller shutter system, ARw=882 m². The vertical openings between the roof slabs (ARr) with the area of the upper opening ARr,1=280 m² and the lower vertical opening ARr,2=127 m² effectively helped the flow regime. In total, there were 2.7 m² of structural openings per animal in barn A which positively influenced lower concentrations of harmful gases.

Large-cubature buildings prevent quick changes in the environment and large openings are a guarantee to the possibility of rapid air exchange. If the roof covering is thermally insulated and sufficiently protects the overheating of the structures, the larger air volumes around the animals, act as a buffering factor for the cleaning period of the buildings even in cases of midday solar radiation. More detailed research is needed to assess the overall decline in production parameters attributable to the occurrence of extreme summer heat situations at a particular farm location and the balance of benefits of using motor ventilation.

The research presented in this scientific paper is supported by the Ministry of Education, Science, Research and Sport of the Slovak republic, by the project VEGA 1/0709/21: “Scientifically justified proposals for technological solutions of housing facilities ensuring optimal microclimatic conditions for livestock and their practical verification”.

[1] Armstrong, D. (1994). Heat stress interaction with shade and cooling. J Dairy Sci 77(7), 2044–2050.

[2] Dimov, D., Marinov, I., Penev, T., Miteva, Ch. & Gergovska, Z. (2019). Animal hygienic assessment of aircarbon dioxide concentration in semi-open freestall barns for dairy cows. Bulgarian Journal of Agricultural Science, 25(2), 354-362.

[3] Fournel, S., Rousseau, A.N., Laberge, B. (2017). Rethinking enironment control strategy of confined animal housing systems through precision livestock farming. In: ö, 155, 96-123.

[4] Hempel, S., Menz, C., Pinto, S., Galan, E., Janke, D., Estelles, F., Müschner-Siemens, T., Wang, X., Heinicke, J., Zhang, G., Amon, B., del Prado, A., Amon, T. (2019). Heat stress risk in European dairy cattle husbandry under different climate change scenarios - uncertainties and potential impacts. Earth Syst. Dynam. Discuss, 1–38.

[5] Herbut, P., Angrecka, S., Godyn, D., Hoffmann, G. (2019). The physiological and productivity effects of heat stress in cattle - a review. Ann. Anim. Sci. 19, 579–593.

[6] Hoffmann, G., Herbut, P., Severino, P., Heinicke, J., Kuhla, B., Amon, T. (2019). Animal-related, non-invasive indicators for determining heat stress in dairy cows. Biosystems Engineering, 199, 83 -96.

[7] Kolacz, R., Dobrzanski, Z. (2019). Animal hygiene and welfare. Univerzity of Environmental and Life Sciences, Wroclaw, Poland, pp. 41, 78–79.

[8] Maurer, D., Koziel, J.A., Harmon, J.D., Hoff, S.J., Rieck - Hinz, A.M., Andersen, D.S. (2016). Summary of performance data for technologies to control gaseous, odor, and particulate emissions from livestock operations: Air Management Practices Assessment Tool (AMPAT).

[9] Poteko, J., Zähner, M. & Schrade, S. (2019). Effects of housing system, floor type and temperature on ammonia and methane emissions from dairy farming: A meta-analysis. Biosystems Engineering, 182, 16-28.

[10] Wang, X., Gao, H., Gebremedhin, K. G., Bjerg, B. S., Van OS, J., Tucker, C. B., Zhang, G. (2018). A predictive model of equivalent temperature index for dairy cattle (ETIC). Journal of Thermal Biology, 76, 165–170.

[11] Witkowska, D. & Sowinska, J. (2017). Identification of microbial and gaseous contaminants in poultry farms and developing methods for contamination prevention at the source. Poultry Science, London: IntechOpen.

Follow us on social media accounts to stay up to date with REHVA actualities

0