Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

Per Kempe |

PhD.PE Teknik & Arkitektur ABGuest lecture at KTH, Building Services and Energy Systemsper.kempe@pe.se |

Energy efficient airtight multifamily apartment buildings are increasingly utilizing central air handling units with higher heat exchanger efficiencies typically between 80% and 90% to obtain low energy use for ventilation. However, the moisture generation in homes creates challenges for the function of residential AHUs. This is partly because the air's ability to contain moisture is strongly temperature dependent, which can be seen in Table 1. Central AHU is preferred to get substantially fewer maintenance points and less heat loss between outdoor air ducts and exhaust air ducts to surrounding indoor air during the winter period. Total heating use for a new multifamily building in Stockholm area is around 25 kWh/m² floor area, year. In such energy efficient buildings, it is important to ensure high quality in design, production, and operation, because each deviation can increase the energy use with a couple of kWh/m² floor area, year. It is not uncommon that the measured (real) heat use become up to 50% higher than the calculated (expected) heat use in energy efficient buildings.

The moisture generation in Swedish apartments buildings is about 2.0 g / kg air, which is much higher than in office buildings. The moisture generation in apartment buildings comes from people, personal hygiene, potted plants, cooking, clothing care, etcetera. Depending on the behaviour of the resident, the moisture generation can be even greater.

Table 1. Examples of moisture content in outdoor air at different outdoor temperatures and a moisture generation of 2.0 g/kg air in the building will give a relative humidity for 21°C extract air with corresponding dew point temperature.

Outdoor air | 0°C, 80%RH | −5°C, 80%RH | −10°C, 80%RH | −20°C, 80%RH |

Moisture content outdoor air | 3.0 g/kg air | 2.0 g/kg air | 1.3 g/kg air | 0.5 g/kg air |

Moisture content in extract air with moisture generation 2.0 g/kg air | 5.0 g/kg air | 4.0 g/kg air | 3.3 g/kg air | 2.5 g/kg air |

Relative humidity 21°C extract air | 32.5%RH | 26.0%RH | 21.5%RH | 16.3%RH |

Extract air dew point temperature | 3.9°C | 0.8°C | −1.6°C | −4.9°C |

Residential AHUs with heat recovery wheel work “better” in winter, compared to plate heat exchangers, as they have significantly less freezing and a certain moisture return. The indoor air does not get as dry during the winter, but AHUs with heat recovery wheel have a relatively large risk of odours spreading in apartment buildings. Residential AHUs with counter flow heat exchangers are hence preferable in apartment buildings to reduce the risk of odour spread but needs defrosting of the heat recovery when the outdoor temperature is below approximately −2°C.

In Figure 1, the heat exchanger is a mix of cross flow and counter flow heat exchanger: We assume that it can be calculated as a counter flow heat exchanger with acceptable accuracy.

| |

Figure 1. Principle sketch of residential AHU with counter flow heat exchanger: | |

| ① Outdoor

air temperature (TOut);

② Preheated air temperature (if used); |

During the winter, when the temperature on the surface of the heat exchanger plate is below the extract air dew point temperature, extract air moisture will condense on the heat exchanger plates and freeze if the heat exchanger plates temperature is below 0°C. To prevent the heat exchanger from becoming a lump of ice, a defrost function is needed to melt the ice in the heat exchanger.

The temperature of the heat exchanger plates, Tplate, on the exhaust side is about the average between the outdoor air temperature, TOut (marked ①in Figure 1), or if preheating is used, the preheated air temperature (marked ②in Figure 1), and the exhaust air temperature, TExh (marked ⑥ in Figure 1). Knowing the temperature efficiency, Effext, and the extract air temperature, TExt, the following equation can be used:

| (1) |

To be able to calculate at which outdoor temperature the plate temperature is about 0°C we reorganize equation [1] to:

| (2) |

Furthermore, Table 2 shows the counter flow efficiency for supply and extract side at different air flow balances, calculated with equations for counterflow heat exchangers that can be found in literature, for instance (Blomberg, P. 1999).

Table 2. Calculated ideal counterflow efficiency with different air flow balances.

Supply air flow / Extract air flow | |||||

Efficiency at balance / Air flow balance | 1.00 | 0.90 | 0.80 | 0.70 | |

70% | EffSup | 70% | 75% | 80% | 85% |

EffExt | 70% | 67% | 64% | 60% | |

80% | EffSup | 80% | 85% | 90% | 94% |

EffExt | 80% | 76% | 72% | 66% | |

90% | EffSup | 90% | 95% | 98% | 99% |

EffExt | 90% | 85% | 78% | 70% | |

The outdoor air temperature to get Tplate = 0°C can be seen in Table 3 and depends on the heat exchanger efficiency on the extract side, EffExt, which can be seen in Table 2 and the extract air temperature.

Table 3. Outdoor air temperature for ideal counterflow heat exchanger to get Tplate = 0°C.

EffExt / Text | 21°C | 22°C | 23°C |

65% | −4.5°C | −4.7°C | −4.9°C |

70% | −3.7°C | −3.9°C | −4.1°C |

75% | −3.0°C | −3.1°C | −3.3°C |

80% | −2.3°C | −2.4°C | −2.6°C |

85% | −1.7°C | −1.8°C | −1.9°C |

90% | −1.1°C | −1.2°C | −1.2°C |

Table 4. Number of hours when the outdoor temperature is below temperatures in Table 3 have been evaluated for a normal weather (typical year) for different Swedish cities (Sveby/SMHI 1981-2010).

Swedish cities | Outdoor temperature | |||

−1°C | −2°C | −3°C | −4°C | |

Malmo | 480 | 310 | 190 | 100 |

Gothenburg | 780 | 530 | 340 | 250 |

Stockholm | 1 300 | 990 | 750 | 590 |

Orebro | 1 730 | 1 410 | 1 110 | 850 |

Umea | 2 400 | 2 000 | 1 700 | 1 500 |

Kiruna | 4 180 | 3 850 | 3 510 | 3 200 |

Heat exchangers in energy efficient multifamily buildings have normally an efficiency between 80% and 90% at air flow balance. Given this efficiency the heat exchanger's plate temperature, Tplate, will become ±0°C or lower when the outdoor air temperature is below between −1°C to −3°C, mainly depending on the efficiency on the extract air side and the actual air flow balance.

One example with 80% efficiency and air flow balance 0.9 and 21°C extract air temperature the condensation and frosting will begin at −3°C outdoor temperature and extract air relatively humidity 25%.

Conclusions: Table 4 shows that residential AHU in north and middle of Sweden needs good defrosting functions to work properly and energy-efficiently especially if the moisture generation is high in the apartment building.

It is important to have a negative pressure in the apartment buildings to reduce the risk of moist indoor air leaking into the building envelope and condensing during the winter with risk for moisture damages. Ten percent lower supply air flow related to extract air flow in each apartment is often sought, which in an apartment building with a high air tightness gives a negative pressure of approximatively 5 Pa. If the deficit becomes larger, the negative pressure increases rapidly and when it exceeds 25 Pa, children, the elderly and others with reduced strength have problems opening doors.

The negative pressure from air flow imbalance causes outdoor air to leak into the apartments, which gives a heat demand, but the negative pressure also reduces the air leaking due to wind (EN ISO 13789, Annex C). So, the total heat demand will be less than the heat demand due to the airflow imbalance.

The under-pressure in the apartments can be determined from the air flow difference (extract air flow – supply air flow) in apartments and the result from blower door test (airflow – pressure relation).

During the last year approximately 100 residential air handling units, AHU, were analysed in two studies for winter and summer period (Kempe, P. 2021, Kempe, P. 2022). In the analyses, a couple of AHUs were found to have problems with AHU functions when frosting, which is presented below.

Most of the analysed residential AHUs are in Stockholm, Gothenburg and Orebro. Measured data (mainly 5- or 10-minute sampling interval) from AHU and technical documentation were provided by the property owners' operating staff. Sensors vary between different AHUs, so the analyses that can be done varies. Measurements of the extract air relative humidity are not common but were added as desired on a couple of the analysed AHU.

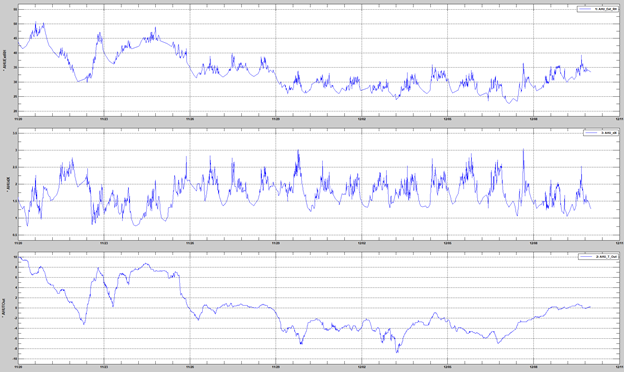

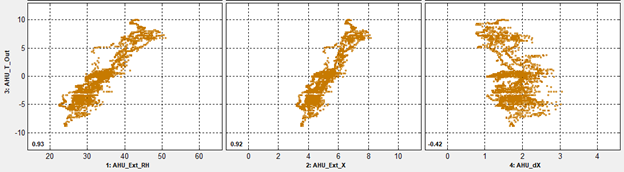

In Figure 2 is shown time series of measured 10-minute data for extract air relative humidity, moisture production (extract moisture content – supply moisture content) and outdoor temperature with cross correlations.

Extract air relative humidity varies between 29–39% RH when outdoor temperature is 0°C and 23–33% RH when outdoor temperature is −5°C and the moisture production is about 1,5 – 2,5 gr/kg air. Other apartment buildings have both higher and lower moisture production depending on resident behaviour.

Figure 2. Extract air relative humidity, RH, extract moisture content, X, moisture generation, dX and outdoor temperature for an AHU investigated 20 November – 10 December 2021.

A couple of common defrosting functions

· Preheating the outdoor air to −1°C to −4°C to avoid frosting and the need for defrosting using geothermal energy, district heating or electric heating.

· Section defrosting controlled by the pressure drop over extract air side of the heat exchanger. During defrosting, heat recovery might be halved with increased need for re-heating.

· Section defrosting controlled by outdoor temperature with increased need for re-heating, which can be combined with supply air flow reduction, which increase room heating.

· Section defrosting controlled by outdoor temperature and extract air relative humidity with increased need for re-heating, which can be combined with supply air flow reduction, which increase room heating. Extract air dew temperature is calculated and compared with heat exchanger plate temperature to control defrosting.

At very cold climate, a combination of preheating and section defrosting can be needed.

Below, potential problems with defrosting are illustrated by six examples.

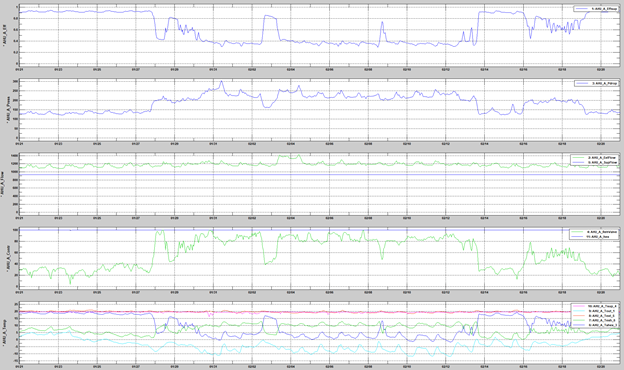

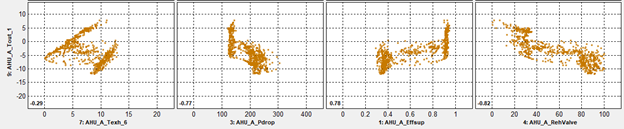

AHU_A has a high moisture load, so it has a lot of defrosting and a very low efficiency, 30 – 40%, for more than half of the period shown in Figure 3 and the pressure drop is high, 200 – 250 Pa. The temperature, ③ after the heat exchanger is −2°C to +5°C, which is very low and require more reheat energy. A similar AHU also with a high moisture load got a very low return water temperature from the reheating coil, so the AHU stopped to prevent the reheat coil from freezing.

Figure 3. Measurements for AHU_A during 21 January – 21 February 2021.

AHU_B have low moisture load and for some unknown reason the preheating coil was out of order and the reheat coil was not dimensioned to work without the preheating coil. Hence the valve to the reheat coil was fully open, but still the air supply temperature was too low. When the AHU defrosts, the reheat coil got a very low return water temperature and the AHU stopped prevent the reheat coil from freezing.

Furthermore, two other AHUs that both have a proper defrost function but had too long piping between the reheating valve and the reheat coil. So, when the AHU got several defrost cycles close to each other, the reheat coil system got to long time delays so the reheat coil got to low return water temperature. Therefore, the AHU stopped to prevent the reheat coil to freeze.

There were a couple of other AHUs that have a slightly too small reheating coil, so they could not keep the supply air setpoint during defrosting. As a result, the supply air temperature became a couple of degrees too low.

AHUs with preheating by district heating and no reheat coil used too much heat energy, because they needed to increase the supply air temperature due to heat losses from the extract air duct from the apartments to the AHU. Without a reheat coil and the need to raise the supply air temperature one need approximate 5 times more heat energy to a preheat coil compared to a reheat coil, when the preheated air is above 0°C.

AHU_C has section defrosting that is activated when the outdoor temperature is below 0°C and a reduction of supply air flow when the outdoor temperature is below −2°C. In this case the extract air flow and the efficiency began to decrease because of frosting from 5 February and 8 February as the AHU stopped since the heat exchanger had become a lump of ice. Today the defrosting function has been updated and shall now run smoothly.

High moisture generation can be a challenge for the residential AHU functions in cold climate: Therefore, it is preferable to measure extract air relative humidity as well as analysing timeseries of measurements from the AHU control system (temperature, control signals, air flows, etcetera) and optimize the AHU functions.

Blomberg, P. (1999): Experimental Validation of Dynamic Component Models for Simulations of Air Handling Units, KTH, Installationsteknik, Meddelande. Nr 50, 1999 (Ph.D. Thesis).

Kempe, P. (2021): Geothermal preheating, In Swedish, Geotermisk förvärmning - Inventering, analys av mätdata vinter och sommar samt dimensioneringsråd, https://www.bebostad.se/media/5225/2021-05-geotermisk-f%C3%B6rv%C3%A4rmning-av-ftx-inventering-analys-och-rekommendationer.pdf.

Kempe, P. (2022): The gap between designed and measured energy use, In Swedish, Glappet mellan projekterad och uppmätt energiprestanda, SBUF-rapport 14025, Shall be published April 2022. https://www.sbuf.se/.

SvebySMHI (1981-2010): In Swedish, Klimatdatafiler SvebySMHI 1981-2010, https://www.sveby.org/wp-content/uploads/2016/04/Klimatfiler-SvebySMHI-1981-2010.zip.

Follow us on social media accounts to stay up to date with REHVA actualities

0