Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

GIFT ONE Tower.

About

the Author: Gaurangkumar

Patel completed his B.E. (Mechanical) in 2002 from B.V.M. Engineering

College, Vallabh Vidya Nagar and M.E. (Mechanical) from L.D. Engineering

College, Ahmedabad in 2009. He is working at GIFT City as Deputy General

Manager (Mechanical). During his career of 14 years he has served various

organizations designing infrastructure projects, high rise buildings,

commercial buildings, residential building, pharmaceutical and other air

conditioning applications. |

Note:

This article

was published in Air

Conditioning and Refrigeration Journal, December 2017. Copyright

© 2017 Air Conditioning and Refrigeration

Journal. Reprinted here by permission from Air

Conditioning and Refrigeration Journal. This article may not be

copied nor distributed in either paper or digital form by other parties

without permission from Air

Conditioning and Refrigeration Journal. |

GIFT City is India’s first globally benchmarked International finance service centre (IFSC), developed by the Government of Gujarat through a joint venture company named Gujarat International Finance Tec-City Company Limited. GIFT City is a global financial and IT services hub, a first of its kind in India, designed to be at par with or above globally benchmarked financial centres such as Shanghai, La Defense – Paris, London, Hong Kong, Singapore, Dubai, etc. It is being developed on 886 acres (359 hectares) of land comprising of a multi services Special Economic Zone (SEZ) with IFSC and a domestic finance centre.

GIFT City has developed the first phase of world class infrastructure facilities such as:

· District cooling system (DCS),

· Automated waste collection system (AWCS),

· Underground utility tunnel,

· Availability of electricity from two different substations (ensuring 99.999% electrical power availability).

Such quality and magnitude of infrastructure is being implemented for the first time in the country.

District cooling system (DCS) distributes thermal energy in the form of chilled water from a central source to multiple buildings through a network of underground pipes for use in space cooling. The cooling or heat rejection is usually provided from a central cooling plant, thus eliminating the need for separate systems in individual buildings.

District cooling system is known as District heating system when used for heating in colder countries. District cooling or heating systems are widely used across the globe.

DCS consists of three primary components (Figure 1).

1. The central cooling plant.

2. The chilled distribution network.

3. The consumer system or energy transfer station.

Figure 1. District cooling system components.

The central plant generates chilled water with compressor drive chillers or absorption chillers. Large size centrifugal chillers with higher efficiency are usually installed to take advantage of the economies of scale. Apart from energy efficient chillers, the central plant consists of chilled water pumps, cooling towers with condenser water pumps, thermal energy storage tank, electrical power distribution system and control system for centralized automation and control of equipment.

The distribution network consists of pre-insulated chilled water supply and return pipes. These pipes are either buried or in underground trenches.

The consumer system or energy transfer system (ETS) consists of heat exchangers, tertiary circulation pump, chilled water piping in buildings, AHUs and the air distribution system. The heat exchangers exchange thermal energy between DCS chilled water and building chilled water.

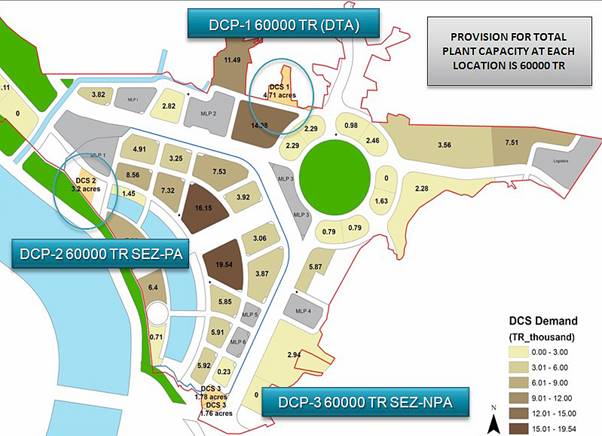

GIFT City has been developed on 886 acres of land with a total built up area of 62 million square feet, and includes commercial buildings, residential buildings, social buildings such as hotel, club and malls, and a hospital. The overall area is divided into three zones based on functionality.

· Domestic tariff activity (DTA),

· Special economic zone – processing area (SEZ – PA),

· Special economic zone – non-processing area (SEZ – NPA).

Figure 2 shows the master plan of GIFT City.

Figure 2. Master plan of GIFT City.

The estimated air conditioning load requirement for these developments will be about 270,000 TR, which requires electrical power demand of 240 MW for the air conditioning load only, considering each building with its own plant.

A feasibility study was carried out between various available systems, and District cooling system (DCS) was finalized considering the following salient advantages:

· High efficiency system – lower energy consumption,

· High diversity,

· Better reliability,

· Lower space requirement at building level,

· Reduced noise and vibration at building level,

· Lower operating and maintenance cost for the centralized facility,

·

Lower

electrical demand for individual building.

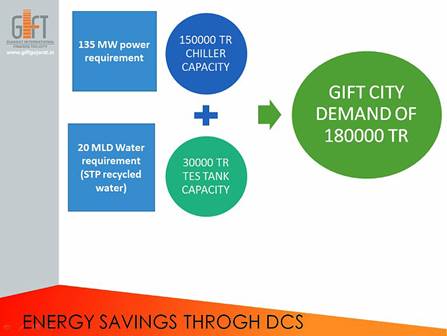

Based on these features, GIFT City has been planned with DCS. The plant capacity requirement will be 180,000 TR considering a suitable diversity factor for development of 62 million square feet built up area for various developments. This brings down the electrical demand to 150 MW. The total requirement of 180,000 TR for the city will be met with three plants of 60,000 TR located such that the distribution network can be optimized.

Each plant has been designed with chilled water based stratified thermal energy storage tank, which can be charged during off-peak period and discharged during peak period, thus bringing down the chiller capacity to 150,000 TR and also reducing the electrical demand to 135 MW only. Thus, electrical demand reduction from 240 MW to 135 MW has been achieved with the help of District cooling system. In line with electrical power requirement, makeup water would also reduce. Figure 3 shows a graphical representation of this.

Figure 3. 180,000 TR DCS capacity.

Based on the above study, GIFT City is proposed to be served with three DCS plants of equal capacity (60,000 TR each). Each plant is proposed to be interconnected through chilled water piping laid in the utility tunnel for improving redundancy. Figure 4 shows the master plan of GIFT City with DCS plant location.

Figure 4. Master plan of GIFT City with DCS plant location.

The chilled water generated at DCS plant will be circulated to each building through chilled water pipes. These pipes are laid in the specially constructed underground utility tunnel. This tunnel houses all city level utilities. It provides huge benefits for installation, operation and maintenance of all systems. Figure 5 shows a view of the utility tunnel.

Figure 5. Utility tunnel.

As GIFT City is planned to be developed in phases based on occupancy growth, the development of DCS plants and utility tunnel for the entire GIFT City would also be taken up in different phases to match the actual city development. It is critical to design the DCS such that it caters to the air conditioning needs of the city at initial as well as peak load stages. Following are the key parameters that were analysed and built into the system design to meet the critical loads as well as cost economics of the overall system:

· Demand assessment

· Planning in line with city development

· Flexibility in plant design

· Optimization of piping network

· Physical infrastructure for current and future scenarios

· Optimization of plant energy consumption

· User satisfaction

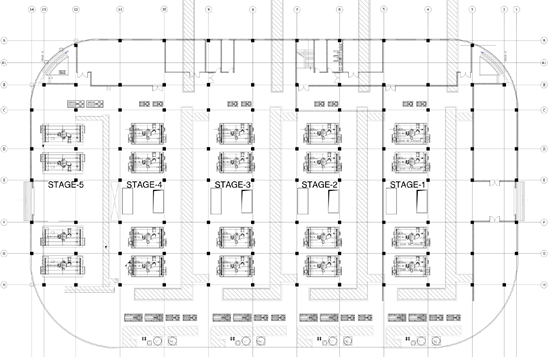

DCS plant is also being developed in phases in line with the phase wise development of the city. At DCP-1 location, the ultimate plant capacity planned is 60,000 TR for meeting the total requirement of the fully developed DTA area. DCP-1 of 60,000 TR will have 50,000 TR of chillers and 10,000 TR of thermal energy storage (TES) systems. Figure 6 shows the phase wise development of DCP-1 chiller plant up to 50,000 TR.

Figure 6. DCP-1 (60,000 TR): 50,000 TR chiller + 10,000 TR TES tanks.

Presently, the Phase-1 (stage-1) plant installed at DCP-1 has a capacity of 10,000 TR. The plant building for DCP-1 has been constructed with special emphasis on the requirement of installation, operation and maintenance space for all equipment. It is a two storey building. The ground floor area, being used for chillers, secondary pumps, TES pumps, HT and LT electrical rooms, has a height of 8 meters. The first floor area, being used for primary pumps, condenser pumps, BMS (control) room and PLC panels, has a height of 4 meters. Cooling towers with RCC basins are mounted at terrace level. The current plant building can accommodate DCS equipment for 20,000 TR capacity, whereas the equipment installed is for 10,000 TR. The salient features of various equipment are listed below.

The chillers are centrifugal type with 2500 TR capacity each and working on 11 kV power supply. The chillersare arranged in series counter flow arrangement to achieve a high temperature difference of 9°C. It means a pair of two chillers will deliver 5000 TR. These are AHRI certified energy efficient chillers with COP of 6.65 at AHRI condition and Non-standard Part Load Value (NPLV) of 0.473.

The 9°C temperature difference reduces chilled water flow to 1.5 GPM/TR. The lower flow rate per ton will provide the following benefits:

· Reduced primary and secondary pump capacity.

· Reduced size of chilled water pipe and other accessories.

· Lower flow rate means reduced energy consumption.

· Higher temperature difference will reduce chilled water energy losses.

Figure 7 shows the installed chiller at DCP-1.

Figure 7. 10,000 TR chillers at DCP-1.

The TES tank with a capacity of 10,000 TR-hr was constructed during Phase-1. It is a stratified chilled water storage tank, which stores thermal energy in the form of chilled water. It is an insulated tank with a diameter of 20 meter and a height of 13 meter. The TES tank will be charged by running the chiller at best efficiency point during off peak period. The TES tank will be discharged during peak load time to cater to air conditioning load beyond the chiller capacity. TES tank of 10,000 TR-hr can cater to 2500 TR load for 4 hours. Figure of merit (FOM) represents the performance of a TES tank. FOM for the installed tank is 0.9. To monitor thermal storage capacity, temperature transmitters are installed at every 300 mm height.

Figure 8 shows the TES tank installed at DCP-1.

Figure 8. TES tank at DCP-1.

All pumps at DCP-1 are horizontal split casing centrifugal type with EEF-1 motor for better efficiency and ease of maintenance. The secondary and TES tank pumps are working on variable frequency drive (VFD).

Figure 9. Chilled water pipe routed below the ground trench.

Chilled water piping and condenser water piping inside the plant are planned in trenches and above 4m for ease of operation and maintenance. Figure 9 illustrates the pipe routed below the ground trench.

The cooling towers are single cell induced draft type with RCC basin. They are CTI certified. The cooling tower fans are VFD driven. Sewage treatment plant (STP) treated water is used as make up water in cooling towers; this reduces the requirement of fresh water. Figure 10 shows the cooling towers.

Figure 10. Cooling towers.

The DCP plant building is air conditioned through chilled water generated at the plant, which helps in increasing the life of all equipment.

Above all, the equipment are controlled and interlocked such that the system can achieve maximum efficiency. DCP-1 plant is designed to generate chilled water at a power consumption of 0.9 kW/TR.

DCS system for 62 Mn sq ft will provide air conditioning at about 0.65 kW/TR.

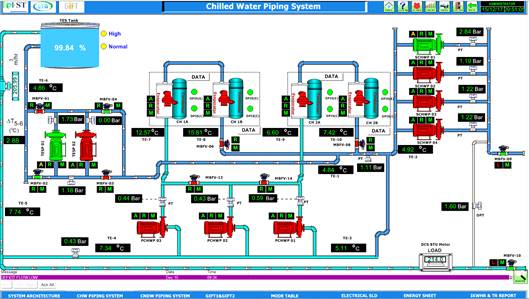

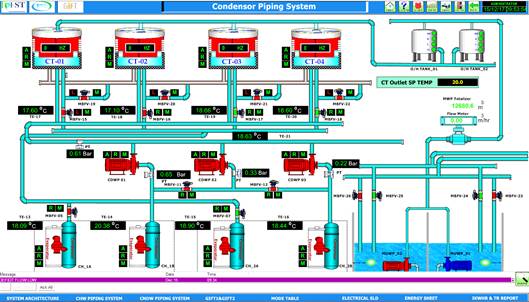

Figure 11 and 12 show the SCADA screens of chilled water circuit and condenser water circuit.

Figure 11. Chilled water circuit (SCADA Screen).

Figure 12. Condenser water circuit (SCADA Screen).

Chilled water generated at DCP-1 is distributed to various building through pre-insulated pipes of 650 mm diameter. The chilled water network laid down in stage-1 is of approximately 3000 m length. Stress analysis was carried out for pipe installation, and expansion joints are provided based on the stress analysis results. These pipes are laid in the utility tunnel with branch tapping for future connection to buildings.

Pre-insulated pipe insulation is designed considering temperature loss of maximum 0.5°C in chilled water distribution. Pre-insulated pipes incorporate an automated leak detection system to detect the exact location of the leakage point, so that rectification if required can be done in minimal time.

The utility tunnel is planned to carry all utility pipes and cables such as raw water pipe, portable water pipe, make up water pipe for cooling tower from STP, blow down water from cooling tower to STP, automated waste collection pipe, data cables, electrical cables, etc. along with chilled water pipes. The chilled water pipes are laid on RCC pedestal at ground level.

The utility tunnel is one of the unique infrastructure features at GIFT City. Figure 13 shows the chilled water pipe installed in the utility tunnel.

Figure 13. Chilled water pipe in utility tunnel.

During the early phase of operation, the available load with DCS was very low due to low occupancy in various buildings. This was expected and considered during the design stage. To operate DCP-1 plant of 10,000 TR efficiently for low load, the following philosophy is being adapted:

· TES tank is charged during night hours with the help of one chiller of 2500 TR. The time to charge is around 4 to 5 hours. The chiller is operated during the night hours to get the benefit of low atmospheric temperature and lower electrical tariff.

· TES tank is discharged during day time and building load is being met by operating the TES tank pump and secondary pump only. Chiller operation is not required during the day time.

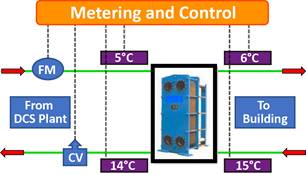

Chilled water supply to each building (User) is measured with an energy meter. The User will be charged based on energy consumption. Figure 14 shows the scheme of metering at each building level. Metering and control on DCS side consists of energy meter, pressure independent control valve and isolation valves.

Pressure independent control valve modulates the flow based on return temperature to ensure 14°C return temperature to DCP, to avoid the adverse effect of chilled water temperature on chiller energy performance.

Figure 14. Metering and control.

To control various parameters at the consumer end (building) and provide DCS facility without any interruption to the end user, special emphasis is given at the design stage itself by working closely with the design consultant of the building and the contractor appointed by the developer. Energy transfer station (ETS) room at each building is reviewed critically by GIFT DCS team in terms of specifications of all equipment such as plate type heat exchanger (PHE) and pumps and operation and maintenance space availability. The scope bifurcation at the interface of DCS and building system is identified.

Control system architecture for District cooling plant is based on redundant PLC and SCADA control system. All automatic and manual logic controls are programmed in PLC. The automatic process sequence and logic functions are developed in ladder and functional block languages.

PLC handles all sequencing control and safeguarding actions. The SCADA operator workstation provides operator interface, including colour graphics, faceplates, alarms, logging, trends, diagnostics, etc.

Figure 15 shows SCADA control room at DCP-1.

Figure 15. SCADA control room at DCP-1.

The consumer system at the building ends consist of PHEs, chilled water pumps, chilled water piping, AHUs and air distribution system. The PHE exchanges thermal energy between DCS chilled water and building chilled water circuit. Figure 16 shows the ETS room at GIFT-ONE Tower at GIFT City.

Currently six buildings in GIFT City, namely GIFT ONE Tower, GIFT TWO Tower, Signature Tower, Tata Data Centre, Aspire-1 and C4 building are air conditioned with the District cooling system. More buildings are under construction and will be working on DCS in the coming years.

Figure 16. ETS room – GIFT ONE Tower.

DCS ensures sustainable development through the following features:

· Lowering down the power demand and energy efficient system operation for air conditioning, reducing CO2 emissions.

· Lower make up water consumption.

· Make up water for cooling tower is treated with water from STP, hence conserving fresh water.

· Chiller is selected with non-CFC green refrigerant gas R134a and the refrigerant is stored at DCS plant location only, thus reducing the environmental impact due to the refrigerant.

· Reducing the plant capacity, which minimizes the use of natural resources.

DCS is an energy efficient and sustainable air conditioning technology for future development in India. DCS technology must be viewed as a solution for increase in atmospheric temperature in urban areas, and promoted and adopted for large scale projects. The installation at GIFT City will go a long way towards inspiring the adoption of this technology by large projects in the country.

District cooling system is a well known and energy efficient technology adopted across the world. District cooling system has been implemented in India for the first time at Gujarat International Finance Tec-City (GIFT City). The first phase of this District cooling system with a capacity of 10,000 TR is in operation since April 2015.

Keywords: GIFT City, District cooling, chilled distribution network, energy transfer station, stratified thermal energy storage tank, diversity factor, utility tunnel

About the Author: Gaurangkumar Patel completed his B.E. (Mechanical) in 2002 from B.V.M. Engineering College, Vallabh Vidya Nagar and M.E. (Mechanical) from L.D. Engineering College, Ahmedabad in 2009. He is working at GIFT City as Deputy General Manager (Mechanical). During his career of 14 years he has served various organizations designing infrastructure projects, high rise buildings, commercial buildings, residential building, pharmaceutical and other air conditioning applications.

Follow us on social media accounts to stay up to date with REHVA actualities

0