Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

| Howard D. GoodfellowUniversity of Toronto, Department of Chemical

Engineering and Applied Chemistry, howard.goodfellow@utoronto.ca |

The

manufacturing and processing industries are facing many challenges today. The

fourth industrial revolution (Industrial 4.0) is happening at an accelerated

rate and many companies are embracing disruptive technologies. This technology

is an extension of the automation field which has seen the use of largely

automatic equipment, including robots in a system of manufacturing or other

production processes. Successful companies must adapt quickly, and new

technical skills are required to implement this revolution. Many companies do

not have technical personnel to implement these technological changes. Skills

include Artificial Intelligence (AI) leaders, researchers, technologists, data

scientists, engineers, etc. All of these innovative changes have a major impact

on the proper design of industrial ventilation systems for the specific

processes. There is an urgent need for a simple holistic model to provide

technical guidance for implementation of Industrial 4.0. A proposed framework

for a Smart Cleantech Model follows.

Cleantech

is a general term used to describe products, processes or services that reduce

waste and require as few non-renewable resources as possible. The goal is to

develop a simple generic software platform for a wide range of industries to

improve global competitiveness. This needs to be a multi-disciplinary approach

(ventilation, sensors, AI) in a lab environment. This approach would require

the integration of best practices for modeling, sensors, big data, and

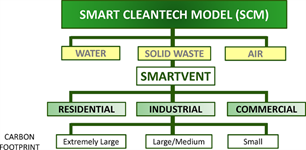

optimization (AI, deep learning). Figure 1 identifies the framework for what

SCM would look like for air (similar structures for the Cleantech model could

be developed for water and solid waste).

Figure 1.

Smart Cleantech Model (SCM).

A component

of this model would be a SMARTVENT model for industrial ventilation which would

be developed for manufacturing and processing plants.

In 2001, a

scientific textbook edited by Howard D. Goodfellow and Esko Tahti

was published by Academic Press. The Industrial

Ventilation Design Guidebook addressed the design of air technology systems for the control of

contaminants in industrial workplaces such as factories and manufacturing

plants. It covered the basic theories and science behind the technical

solutions for industrial air technology and included publication of new

fundamental research and design equations contributed by more than 40 engineers

and scientists from over 18 countries.

Readers were

presented with scientific research and data for improving the indoor air

quality in the workplace and reducing emissions to the outside environment. The

Guidebook represented, for the first time, a single source for all current

scientific information available on the subject of industrial ventilation and

the more general area of industrial air technology. New Russian data was

included that filled several gaps in the scientific literature.

·

Presents

technology for energy optimization and environmental benefits

·

A

collaborated effort from more than 60 ventilation experts throughout 18

countries

·

Based

on more than 50 million dollars of research and development focused on

industrial ventilation

·

Includes

significant scientific contributions from leading ventilation experts in Russia

·

Presents

new innovations including a rigorous design methodology and target levels

·

Contains

extensive sections on design with modeling techniques

·

Content

is well organized and easily adaptable to computer applications

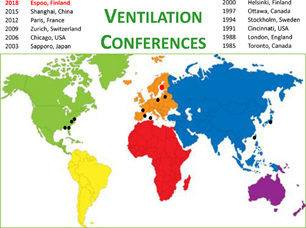

This

comprehensive digest of scientific know-how gained its origin from the

International Industrial Ventilation Conferences that were conceived by

Professor Jim Smith and Howard Goodfellow from the University of Toronto

(September 1985). Figure 2 conveys the ventilation conferences

held every three (3) years with the most recent conference being held in

Finland in 2018. These specialized conferences have resulted in the development

of a critical global mass of engineers and scientists working in the industrial

ventilation field. Since the conference inception, there have been twelve

international symposiums with more than 3000 attendees and over 1250 technical

papers. The 13th International Industrial Ventilation Conference is

now being planned for 2021 in North America.

Figure 2.

International Ventilation Conference Locations.

The

proposed revised guide book covers the area of ventilation for contaminant

control based on global research by world class researchers. This reference

book is unique because it brings together global researchers and engineers to

allow designers and engineers to solve complex ventilation problems using

state-of-the-art design equations. Most of the equations and other scientific

terms can be used in all ventilation and air conditioning fields, not only for

ventilation contaminant control.

The recent

awareness of climate change and a push by all industrial countries to embrace a

low carbon economy has put a high pressure on industry to reduce their environmental

footprint. European countries have taken a leadership role with the

introduction of Industry 4.0 ~ automation plus sensors. For this

to be implemented, engineers and scientists will be looking for a single

reference source to find design equations and methodology to develop control

algorithms for automation. Another key scientific component is the measurement

of process parameters in real time using state-of-the-art sensors in the air

and contaminant fields. These are specific areas that will be presented in

depth for the first time in a detailed format based on global research in the

sensor technology fields. Data will be presented both for leading edge sensor

technology and well proven technology on a global basis.

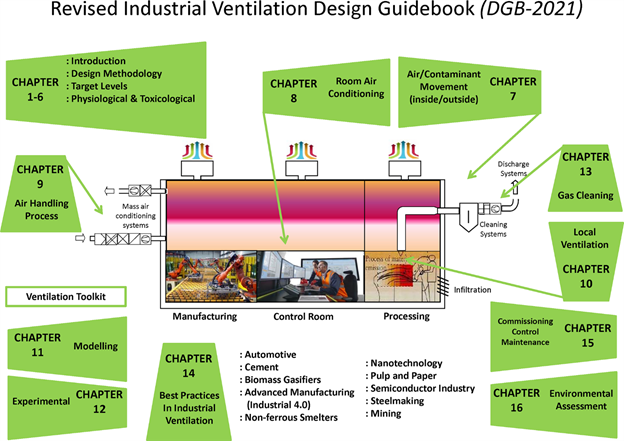

The revised

Industrial Ventilation DGB (2021) will be

unique in the marketplace as it will present a single source for a holistic

approach to industrial ventilation for contaminant control. Details will be

presented for the four key steps:

Step 1: Design Methodology

Step 2: Design Equations

Step 3: Design Toolkits

Step 4: Specific Industrial Examples of Best

Practice for Ten Major Sectors

The reasons

for proposing this newly revised edition is because of the wealth of increase

in new research technology in the broad field of ventilation for contaminant

control on a global scale since the original Industrial Ventilation DGB was

published in 2001. The preparation of the original book took ten years and

major contributors from Europe and Russia where the level of science was the

highest. Specific areas of advancement include: design methodology for

ventilation systems for contaminant control, use of high-speed computers in

modeling capabilities of air-flow and contaminant levels in both the workplace

environment and the external environment, commercialization of the latest

sensor technology such as lasers, etc., and the breakthrough of practical

application of deep learning in the Artificial Intelligence (AI) field.

Our

approach is to achieve harmonization of ventilation technologies on a global

basis. Our extensive list of global experts will present for the first time a

multi-sector cross cutting technology based on a holistic integrated approach

of scientific research and engineering in the industrial ventilation field.

Figure 3 illustrates the major chapters

being planned for the revised Industrial Ventilation DGB (2021). The revised

book will have Professor Howard Goodfellow (University of Toronto) as

Editor-in-Chief. The Co-Editors will be Professor RistoKosonen (Aalto University, Finland) for Volume I – Fundamentals and Professor Yi Wang (Xi’an

University, China) for Volume II –

Engineering Design and Applications.

Figure 3.

Outline of DGB (2021).

New

features of the book will be as follows:

·

Major

new innovative technologies from researchers in China (book will become truly

global)

·

Further

validation of design methodology and target levels based on plant experience

·

Integration

of automation and sensors (Industry 4.0)

·

Closer

collaboration with engineering schools and end users and the design/consulting

communities

·

Focus

on gaps in ventilation using search engines to ensure all recent developments

and innovations are included

·

A

new and expanded section on sensors technology and methodology of selecting the

best sensor for each unique application

·

Section

on modeling and its practical applications will be expanded based on recent

advances in research

·

A

new chapter on Best Practices for specific industrial sectors. The initial

edition will be based on 10 industrial sectors with a proposed template that

can easily be updated in the future to include other industrial sectors. An

outline for the template for Best Practice is presented below

The

template for Industrial Sectors for the Chapter on “Best Practices” for Industrial Ventilation for Contaminant Control – Industry Specific

Sectors for selected industrial sectors includes:

·

Overview

– Role of Ventilation

·

Design

Methodology

·

Design

Equations

·

Design

Toolkits

·

Case

Studies – Best Practice

·

Future

Challenges /Opportunities

·

Selected

Bibliography

Table 1 below illustrates the features and

benefits of the revised Industrial Ventilation DGB (2021).

Table 1. Industrial

Ventilation DGB (2021) – Features/Benefits.

FEATURES | BENEFITS |

Systematic Holistic Approach

to Design | Accelerate implementation of

|

Global team of researchers

and engineers as contributors | Single source of all recent

research and best practice for industrial end users. Benefit for training of

future researchers, designers and engineers to use IOT to achieve energy

efficiencies, cleantech, climate change, etc. |

Innovative state-of-the-art

development of sensors, modeling, deep learning system performance

evaluations, hyper linked equations | Provide key technical inputs

required for challenges of low carbon economy and industrial 4.0 |

The

professional audience faces many issues. The first is that the literature

(research and engineering) is highly fragmented in the research world (no

specific home and often in different disciplines in different countries). The

proposed book will provide a single source for relevant research and

engineering in the industrial ventilation for contaminant control field.

A second

issue is that many of the text books, reference books and engineering books in

this field have not been updated for a couple of decades or so, and do not

reflect state-of-the-art for ventilation technology today and do not include

the significant innovations in design criteria, modeling, sensors, AI (deep

learning), etc., that are available to meet the new challenges of

sustainability and a low carbon economy. The proposed book will focus on these

recent developments.

The target

audience will be at two levels and for a multi-sector industrial approach for

processing plants and manufacturing. The proposed two levels for this revised

DGB will be to bring researchers, engineers (both design and plants) and

scientists to develop a fundamental scientific understanding of ventilation and

to provide trained engineers to implement this state-of-the-art ventilation

technology on a global basis. It is envisaged that the revised Industrial

Ventilation DGB can be used as a core text book in an academic setting for

mechanical engineers and process engineers. It is envisaged that it can be used

as a background for specific industry based 1–5 day

workshops and for plant and process engineers looking for a design methodology,

sensors and control algorithms for specific industrial operations to meet the

challenging low carbon economy. The textbook will also be a valuable reference

book for consulting engineers working in the design of air pollution and

sustainability for their industrial clients (processing and manufacturing).

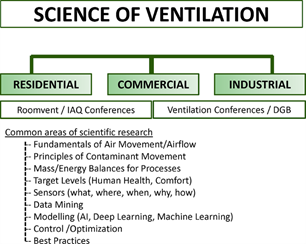

The science

and technology of industrial ventilation is at a crossroads and key decisions

need to be made to capitalize on the unbounded opportunities. Three key areas

to be pursued are:

·

Better

communication (scientific and engineering community of ventilation and

contaminant control)

·

Develop

a global collaborative community

·

Embrace

disruptive technologies (sensors, modeling, automation, AI, etc.)

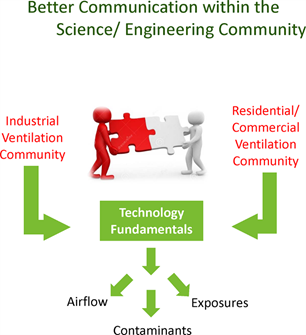

In the area

of better communications, it is important to recognize that there are many

common areas of scientific research and engineering in the ventilation and

contaminant control field. The goal is to develop a holistic approach for the

science of ventilation. Figure 4 illustrates many of the common

areas of science and technology for the residential, commercial and industrial

sectors.

Figure 4.

Science of Ventilation.

The second

area is to develop a global collaborative network in the ventilation technology

field. This global network would include scientific research (academic,

research institutes), professional associations (ASHRAE, REHVA, SHASE),

international technical conferences, low carbon economy, disruptive

technologies (Industrial 4.0, AI, sensors, etc.), scientific publications

(revised Industrial Ventilation DGB (2021)). Success depends on a holistic,

multi-disciplinary and a sustainable funding model. An excellent example of

this goal to breakdown the silos is the leadership shown by ASHRAE President

Professor Oleson in his August 2017 article in ASHRAE Journal entitled, Extending

our Community. The specific goals outlined in the report was the

urgent need for the ventilation community to “extend the global community” and to “extend

the technological horizons.”

Figure 5 illustrates a model for better

communications with the science and engineering community.

Figure 5.

Communications Model.

Disruptive

technologies are happening at an accelerated rate and will have a major impact

on the future directions of the science and technology of industrial

ventilation. Disruptive technologies such as robotics, AI, models for low

carbon economy, innovative sensors, etc., are impacting many sectors and

researchers must embrace the cross transfer of these technologies. For example,

innovative sensors are being developed that are wireless, non-invasive, cheap,

remote, in-situ. Many of these sensors have wide applications for many

different sectors (ie. autonomous vehicles) for

advanced design of ventilation systems.

In

summary, I urge all researchers and engineers BOLD EMBRACE LEARNING SUCCESS DEPENDS On SIMPLICITY The issue

is never how to get new innovative thoughts |

1. Goodfellow, H.D., Tahti,

E., eds, “Industrial Ventilation Design Guidebook” Academic Press, 2001.

2. Goodfellow H.D., et al “Industrial

Ventilation – A Review and Update” AIHAJ, March 1982, Volume 43, No.3, pg.

175-184.

3. Oleson, B.W., “Extending our Community”

ASHRAE Journal, August 2017, pg. 14-21.

[1] This article is an invitation to any REHVA researcher/expert/engineer/practitioner

interested to contribute to any specific section of the revised DGB to contact Howard

Goodfellow indicating the areas of interest. Contact quickly, as the Chapter

leaders have already been selected by the Co-Editors but we need to make sure

that we include the best science and best practices for industrial ventilation

from the global community. We are also looking for reviewers for specific areas.

Follow us on social media accounts to stay up to date with REHVA actualities

0