Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

Bjarne W. Olesen | Lennart Østergaard | Jannick K. Roth |

Intl. Centre for Indoor environment and Energy, Technical University of DenmarkE-mail: bwo@byg.dtu.dk | VELTEK Ventilation, the Danish Ventilation Association | WindowMaster International A/S |

The Danish Standard DS 447 "Ventilation in buildings - Mechanical, natural and hybrid ventilation systems" has been revised and a new edition was published in January 2022. DS 447 is the governing system standard for ventilation systems and is referred to in a normative way in the Danish Building Regulations. Even though the building regulations refer to DS 447, the building regulations still contain requirements for ventilation in residential buildings, day care, and classrooms. DS 447 covers standardization on ventilation in buildings and ensures implementation of European standards for building ventilation and indoor climate.

The standard consists of the following sections and annexes:

Normative sections:

· Assumptions and input parameters for the indoor environment

· Mechanical ventilation

· Natural ventilation

· Hybrid ventilation

· Testing, balancing, handing over, documentation and operation

Informative annexes:

A. Examples of setting up indoor climate requirements and deviations (residential, office, school)

B. Ventilation efficiency

C. Draught rate

D. Dynamic calculation of concentrations of pollutants

E. Ventilation systems, designs and principles

F. Residential ventilation

G. Ventilation in large kitchens

H. Design methods for natural ventilation

I. Ventilation and spread of infection

The standard sets requirements for ventilation and ventilation systems in all types of buildings, intended for human occupancy.

The purpose of the standard is to ensure that ventilation systems are designed, installed, and can be operated and maintained in a technically, hygienically, and functionally sound manner, e.g., considering comfort and energy efficiency. The standard contains provisions regarding the design, execution, testing and operation of ventilation systems, as well as provisions for products and components used for the ventilation systems.

The standard includes normative parts, that must be met, and notes that give guidance and recommendations.

For the design the assumptions and requirements for the ventilation system in relation to system selection, atmospheric, thermal, and acoustic indoor environment, the users' ability to influence the conditions, and noise to the environment must be set at room level or room type.

Annex A gives examples of indoor climate requirements and acceptable deviations for typical building types / rooms. The basis for the recommendations is IEQ level II in DS / EN 16798-1: 2019 with the national Annex A (DK-NA: 2022). An example for the recommendations for the atmospheric environment is shown in Table 1.

Table 1. Ventilation requirements in an office building. IEQII for very low polluting building

Room | Single | Open plan | Meeting | Source: DS /EN16798-1 & -2 | Comment |

Occupancy, m²/pers. | 10 | 15 | 2 | IEQII Table B.6 /2 |

|

Relative Humidity, % | 25 < RH < 60 | IEQIIDS /EN 16798-1:2019 DK NA:2021, Table NA.16 | Design de- and humidifier. Control of ventilation Absolut humidity < 12 g/kg | ||

Ventilation ℓ/s m² | 1,1 | 0,8 | 3,9 | Part 2 IEQII Table B.6 | Ventilation outside occupancy DS /EN 16798-1:2019 DK NA:2021 (NA.3.3.1) |

Equivalent ∆ CO₂ | 529 | 454 | 722 | Part 2 IEQII Table B.11 |

|

During non-steady conditions like meeting rooms the volume of the room and the duration of the stay may be considered when determining the outdoor air supply (Annex D).

The recommended room temperatures for winter (heating, 1.0 clo) and summer (cooling, 0.5 clo) are based on DS /EN 16798-1 category II both for buildings with mechanical cooling/ventilation and building with natural ventilation and window opening. In the CEN standard there is no guidance for temperature criteria in the shoulder seasons (spring and fall). In DS the shoulder season is defined as periods where the 7-day running mean outdoor temperature is between 10°C and 15°C. In this period the recommended operative temperatures are 21.5–25°C based on a 0.75 clo clothing. In offices due to a little higher physical activity on arrival at work, it is allowed to start with 1 K lower room temperature the first hour of use. This increases the potential for using night cooling and by night set-back start the heating later.

In the project the agreed deviations from the specified requirements should be documented according to the recommendations in DS /EN 16798-2.

To achieve the requested indoor climate, different principal technological paths are available to the designer. For the former DS 447:2013, also available in English, the Danish standardization committee decided that both mechanical, natural and hybrid ventilation should be allotted equivalent sections of the standard, describing the technological requirements when a principal technological path has been chosen. Furthermore, as the purpose of the ventilation system is to achieve a certain indoor climate, it was decided that the requirements for the indoor climate had to be the same, regardless of technological solution.

This has proven a wise decision, as it gives the designer the freedom to choose type of system, but it has also given the customer the certainty that the system will fulfil the requirements for the indoor climate, regardless of system type. This important principal structure of the standard has been maintained in the new version DS 447:2021.

One key issue in the Danish market is that the design of ventilation systems is increasingly pushed forward in the value chain. Thus, it is often no longer the consulting engineer that design the system – they primarily describe the requirements on the resulting indoor climate and refer to legislation and standards. The actual system design is left for the contractor, who often has more scarce competences and resources for such a task.

To improve the quality of the installed systems, the standard has been expanded with the absolute minimum requirements for system design, in particular requirements for the project documentation, e.g., declaration of the design air flows on room level and through air inlets, specification of air distribution principles, heating/cooling capacities, also considering the room usage, geometry, orientation etc. Noise, energy consumption, space for service and maintenance and many more parameters must also be declared in the documentation.

The mechanical ventilation chapter is updated and based on European standards.

The chapter on mechanical ventilation has undergone an important revision such that it now focuses entirely on system and product requirements. All requirements on balancing, air tightness testing, hand over etc. has been moved to a new chapter focusing on the hand-over stage of the project life cycle.

For the mechanical ventilation chapter, European standards form the principal basis for all requirements and key elements are included in tables. It was discussed whether a revised new Danish ventilation standard was at all needed, since we now have relevant European standards for the entire topic. The conclusion was that the stakeholders in the Danish building industry would benefit from a standard in Danish, containing core requirements, tables, and content, and providing an overview and references to all the relevant European standards.

The chapter has been expanded a few places where the technological and market developments has proven this to be necessary, see Table 2.

Table 2. Some examples of expansions implemented in the new Danish standard, and their motives.

Expansion implemented | Motives |

A more detailed list of requirements for the accessibility and space requirements for components has been included. | Projects often do not assign sufficient space for service and maintenance. |

More strict requirements on the exhaust from range hoods have been included for renovation of apartment buildings. | More and more projects see solutions where the exhaust is established through the façade of the building – and thus polluting the air intake of neighbouring apartments. |

New classification requirements on small non-ducted single room alternating ventilation units have been included. | Such units are vulnerable to pressure differences on the facades, leakages when not in operation, short-circuit of the air flows - and the heat recovery efficiency needs to be calculated in a special way. |

The section on filtration has been updated with the filter classifications in the new EN 16890, and recommendations for filtration efficiencies for a given outdoor air quality (ODA) and a required supply air quality (SUP), based on EN 16798-3, have been included. | A desire and benefit expected from harmonizing with existing European standards; EN 16890 and EN 16798-3. |

The sections on humidification and enthalpy heat exchangers are expanded | Dry indoor air during the winter has been identified as an increasing problem in Denmark. |

Natural ventilation is defined as ventilation which utilize natural driving forces.

The main aim of the natural ventilation chapter is to secure that the system is being well designed, installed, operated, and later in chapter 9 maintained properly. The focus for this recent update of this chapter was to implement a set of minimum documentation levels to be full filled.

One important aspect is the design stage which now includes methods such as analytic and dynamic simulations. For the specific project calculation, you need to state and include parameters like ventilation principle, pressure coefficients, control of the openings, effective opening areas at maximum and common operating modes etc.

Natural ventilation needs to be automatic controlled to secure the basic ventilation rate. The opening degree of the openings needs as a minimum to be determined based on the wind effect as well as indoor and outdoor temperatures as these are the driving forces. Different operating strategies like nighttime cooling and intermittent ventilation (pulse ventilation) shall be included in the control strategy of the natural ventilation system for winter, summer, and the transition period.

Requirements to components, ducts and shafts, sensors etc. is also an important part of this section.

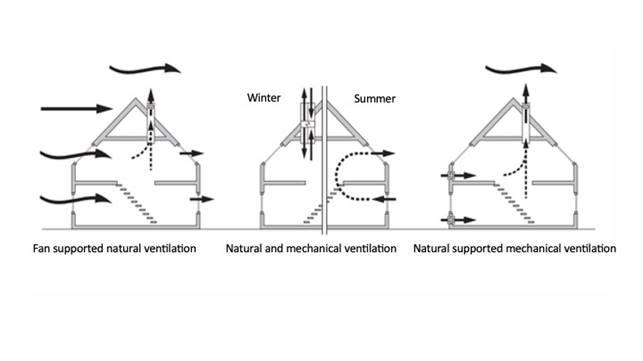

Hybrid ventilation is defined as a combination of natural and mechanical ventilation.

The hybrid ventilation chapter contains additional requirements which isn’t described in the natural or mechanical ventilation chapters. The essential of the hybrid section is not only to fulfill requirements in the natural and mechanical ventilation chapter, but to be able to take the interaction of the natural and mechanical ventilation into account. This is especially important in the design stage where the control and operating strategies should be implemented and handled to get a realistic picture of the performance of the system.

Hybrid system can utilize the same air flow path when in natural- as well as mechanical ventilation mode. An example could be a mechanical ventilation component (fan) located in a shaft used when the system runs in mechanical mode. The same shaft is then also being used as the natural air flow path when the system runs in purely natural ventilation mode. Here it is important that the fan doesn’t reduce the natural ventilation air flow below acceptable limit. Considerations like these are crucial in the design phase.

Examples of different hybrid ventilation systems.

Unfortunately, Denmark is often the scene for very poor installation of ventilation systems. Some projects end up in public scandals, with project stakeholders fighting each other. There are many erroneous and problematic projects in the field. The revision committee has attempted to build a new chapter for the testing, balancing, hand over, documentation, training, service, and maintenance requirements for ventilation systems. The former standard did include some of the requirements, but they were partitioned over different chapters, resulting in a lack of overview for the contractor.

For air tightness testing of ventilation systems, the standard now includes expanded requirements. Guidance regarding the required documentation, including documentation for the air tightness testing setup, is included. Should the contractor decide to test using samples, it is also described that minimum 25% of the ducts must be tested, and should the samples fail, 100% of the duct system must be tested.

The section on balancing of the systems is also expanded, and now included the maximum allowed measurement uncertainties on the testing equipment (based on EN 12599).

The standard has made a new and much more detailed section on testing of the entire system before handover. The list of activities in this regard follows the description from the REHVA Guidebook no. 29 on Quality Management of Buildings.

A very elaborate list of the required system and user documentation has also been written.

A new requirement on system training at handover has been written. Often, in the past there had been no budget left for training in actual projects.

The Danish Standard DS 447 is applicable for mechanical, natural and hybrid ventilation systems and has just undergone a revision which was published in December 2021. One of the strengths of this standard is to set minimum requirements for each specific ventilation system technology and have some overall requirements to the indoor environment. The requirement to the indoor environment is mainly based on the Danish Building Regulation, DS /EN 16798-1: 2019 and the national Annex A (DK-NA: 2022). To help the user Danish Standard has decided to include the Danish national Annex A, when you buy DS 447.

Follow us on social media accounts to stay up to date with REHVA actualities

0