Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

Arnaud MiratonProject ManagerEuroventCertita Certification |

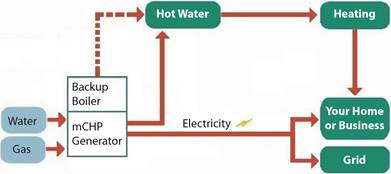

Gas fueled micro-Combined Heat and Power units refers to

technologies fueled with gas that generate both heat

and electricity at the same time and with an electricity power lower than 50 kW.

The CHP technology has been used in the industrial sector since the 1960s but

through technological development it has been adapted for domestic heat and

power needs. The mCHP generators used in the unit are

mostly internal combustion engines (ICE), Stirling engines and fuel cell

technologies. The units commonly called mCHP boilers,

are widely presented as the boiler of the future because of its high level of

efficiencies and its consistency with the heat and power needs of low-energy

housing.

Figure 1. mCHP process diagram.

The NF

certification scope covers gas fueledmCHP units using an internal combustion engine, Stirling

engine or a fuel cell technology. Units considered are gas fueled

units that may include, as the case may be, a heat accumulator or/and a backup

boiler. Units must be delivered as a complete unit or assembly of components

referenced and designed to be installed together.

The

technology has known up to now a non-uniform deployment through the World and

Europe. Japan is considered as the precursor especially for fuel cell

technologies, in Europe Germany has the lead. Several experimental demonstrations

have been realized at European and National stages such as the ENE FIELDS

project (1000 housings equipped in 11 European countries), the CALLUX project

(800 units deployed in Germany) or EPILOG project in France… The technology has

proved its worth and waits know to be fully supported and deployed in the

European energy landscape.

The

regulatory environment has evolved recently in France to consider these

technologies on the market. In Particular, a decree for Feed-in tariffs for

electricity (C16 decree) has been published, defining the electricity

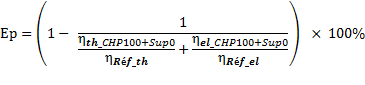

purchasing prices of mCHP units. The purchasing

prices are defined according to the Primary Energy Savings (Ep) of the unit,

calculated as follow based on the thermal end electrical efficiencies (η)

of the machine, both certified in the NF mCHP

certification scheme:

As well the

French Thermal regulation for buildings (RT2012) has been updated to consider

fully the three technologies of generators in the calculation tools.

At the

European stage, two key regulations are considered in the scheme, the Ecodesign and Energy labeling (ErP) and the European regulation for gas appliances. More

specifically, the ErP has been completed with two

application regulations that deal with mCHP boilers: the

regulations 811/2013 [1] and 813/2013 [2], both giving accurate expectations

and thresholds on the performances of the units.

The NF

certification brand, well-known in France and through Europe, guarantees the

level of performances and product quality declared by the mCHP

manufacturers. It generates clarity and transparency on the market, display

understandable information on the performances and product quality, enabling

end-users to compare objectively the products on the market.

The NF mCHP certification process is a reliable and robust process

that includes yearly factory assessment audits and third-party product testing.

The testing protocols, calculation methods, and denominations have all been

harmonized to rate fairly and identically the products on the market.

Figure 2.

NF mCHP marking.

The testing

methods are based on the European testing standards EN 50465 March 2015 “Gas appliances - Combined heat and power appliance of nominal heat

input inferior or equal to 70 kW” and EN

15036-1 mai 2007

“Airborne noise emissions from heat

generators”.

Table1.

Certified performances.

Micro-combined heat and power unit | ||

Performance | Denomination | Threshold |

Nominal thermal capacity (kWth) |

| - |

Thermal efficiency (%) - based on lower heating value |

| - |

Electrical efficiency (%) - based on lower heating value |

| - |

Global efficiency (%) - based on lower heating value |

| - |

Seasonal Efficiency (%) |

|

|

Auxiliary Electrical Energy Consumption (kW) |

| - |

Electrical nominal power (kWe) |

| - |

Standby mode losses (kW) |

| - |

Auxiliary energy in standby mode (kW) |

| - |

Thermal minimal power (kWth) |

| - |

Nitrogen oxides emissions (mg/kWh) |

| NOx < 70 mg/kWh

(Stirling) |

Sound Power level(dB) |

| - |

Annual consumption of heating combustibles (GJ PCS) |

| - |

Principal heat and power generator | ||

Nominal thermal capacity (kWth) |

| - |

Thermal efficiency (%) - based on lower heating value |

| - |

Electrical efficiency (%) - based on lower heating value |

| - |

Global efficiency (%) - based on lower heating value |

| - |

Auxiliary electrical energy consumption (kW) |

| - |

Auxiliary heat generator | ||

Nominal thermal capacity (kWth) |

| - |

For further

information on the NF mCHP certification scheme or to

apply for the certification, please feel free to contact EuroventCertita Certification (apply@eurovent-certification.com) specifying “NF-Micro Combined Heat and Power”

in the mail object. There is no deadline as this is a voluntary registration.

[1] COMMISSION DELEGATED REGULATION (EU)

No 811/2013 of 18 February 2013 supplementing Directive 2010/30/EU of the

European Parliament and of the Council with regard to the energy labelling of

space heaters, combination heaters, packages of space heater, temperature

control and solar device and packages of combination heater, temperature

control and solar device.

[2] COMMISSION REGULATION (EU) No

813/2013 of 2 August 2013implementing Directive 2009/125/EC of the European

Parliament and of the Council with regard to ecodesign

requirements for space heaters and combination heaters

Follow us on social media accounts to stay up to date with REHVA actualities

0