Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

Rauno Holopainen | Olli Seppänen | Siru Lönnqvist |

Metropolia University of Applied Sciences, Finlandrauno.holopainen@metropolia.fi | The Finnish Association of HVAC Societies, FINVAC, Finland | The Finnish Association of HVAC Societies, FINVAC, Finland |

|

|

|

Mervi Ahola | Samuli Könkö | Jorma Säteri |

Finnish Society of Indoor Air Quality and Climate, Finland | The HVAC Association of Finland, SuLVI, Finland | Metropolia University of Applied Sciences, Finland |

The EU Commission has published a final report (EU 2020) on inspection of the stand-alone ventilation systems in buildings. The report emphasizes the importance of regular inspections of ventilation systems after they are commissioned. According to the Finnish law (ME 1009/2017), air flows and other important parameters of new ventilation systems must be measured before they are handed over to the building owner. Periodic inspections are not mandatory after commissioning.

The request for a new ventilation inspection method came from the Ministry of the Environment in Finland (FINVAC 2021). The need to improve the performance of ventilation systems originated from the common complaints related this. The ministry made a contract with FINVAC for the development of low cost, and quick inspections of ventilation systems. The previously published guides, such as CEN/TR 16798-18 (2017), were considered too expensive to implement as the first stage of inspection. Existing systems such as the Swedish OVK (Boverket 2021, Ekberg 2021) were investigated but they did not meet the identified requirements. The Finnish government preferred also a voluntary inspection, not mandatory inspection as in Sweden. The period between regular inspections was set to three or five years, depending on the type of ventilation system.

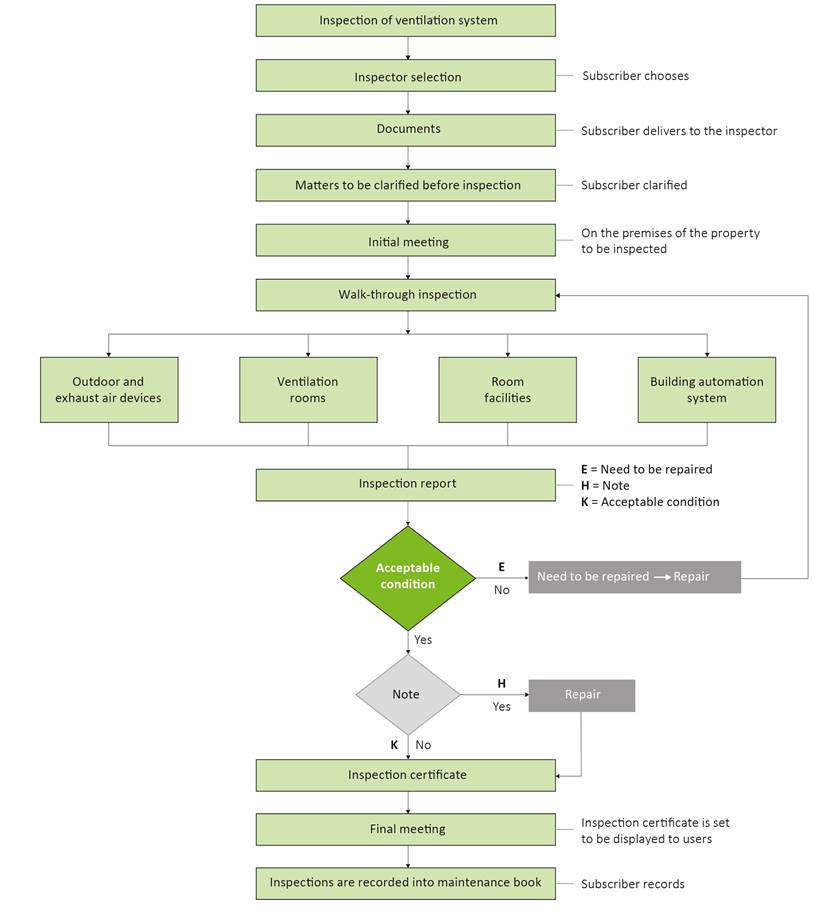

Stages of the walk-through inspection are shown in Figure 1. The inspection process begins with selecting a qualified inspector and ordering an inspection. In the beginning, the building owner or its representative (subscriber) collects and submits the necessary documents to the inspector before, or at the latest, in the initial meeting at the building site. It is recommended that the subscriber collects the latest month's trend data on the use of ventilation and indoor air quality from the building automation system for the inspection. This will reduce the inspection time and costs. The ventilation system is examined during a structured walk-through inspection with the service and operational personnel of the building. The condition of the ventilation system is recorded by taking photos during the inspection. The inspection ends with a final meeting and a presentation of the results to the subscriber. The inspection report and the inspection certificate are saved in the building’s maintenance book.

Figure 1. Stages of the walk-through inspection.

The walk-through inspection covers the following items: design, operation and maintenance documents of the ventilation system, condition and functioning of the system and its components, air flows in the duct work and to the rooms, balance of the air flows, operation and maintenance of the system and its components, cleanliness and hygiene, fire safety, performance and schedules of building automation system, perceived indoor air quality and environment, and energy efficiency. The inspection is performed mainly using sensory evaluation. Pressure difference is measured for critical components of the system such as fans, and rotary heat recovery units. In addition, the pressure differences over the building envelope are measured. Table 1 summarizes the content of the inspection.

Table 1. Items to be inspected in the ventilation system.

Documents | · Design drawings · Control and operation diagrams · Airflow measurement and reports · Differential pressure measurement and report (buildings with a tight envelope) · Duct cleaning reports · Inspection intervals and maintenance schedule of ventilation system in accordance with maintenance contract of property |

Condition and functioning | · Functioning of ventilation components such as fans and dampers · Balance of air flows · Air distribution |

Operation and maintenance | · Schedule of ventilation operation · Setpoints of supply air temperature · Maintenance and repairs recorded in maintenance log book |

Cleanliness and hygiene | · Cleanliness of air handling unit, components, ducts, and terminal units · Condition of insulated surfaces · Bypasses of supply and exhaust air filters |

Fire safety | · Fire dampers and insulation of ventilation ducts |

Building automation | · Performance and operation of control system for ventilation and air conditioning processes |

Indoor environment | · Air temperature and carbon dioxide concentration · Feedback from occupants |

Energy efficiency | · Type and functioning of heat recovery system |

The inspection of the ventilation system begins with the initial meeting, which is attended by an inspector, the property maintenance worker, the person in charge of the building automation system, the subscriber, and a user representative. The initial meeting deals with the deficiencies found in the documents and the facilities to be inspected.

The walk-through inspection covers all rooms with air handling units, roof top units, and exhaust fans in accordance with the safety regulations and rules. Approximately 20% of the rooms in the operation area of each ventilation system are inspected. In buildings with a floor area under 300 m², all the rooms are inspected. The rooms are selected for inspection through an inspection that is carried out on each floor that the ventilation system serves, and the selected rooms must represent typical use. In addition, rooms with several occupants and rooms with complaints about indoor air quality are also selected for the inspection. The inspector checks the condition, functioning and cleanliness of the ventilation system components during the walk-through inspection, takes photos of the faults and records them in the inspection report. The need for further investigations or measurements is added to the report, if the reasons for poor operation or conditions cannot be specified in the sensory inspection.

The inspector evaluates the ventilation system’s condition, functioning and needs to be cleaned using the following scale: E = condition not acceptable (needs to be repaired), H = weak condition (note) and K = acceptable condition (functions as intended). The inspection interval must be taken into account when evaluating the condition of the system, and ventilation must remain in acceptable condition during the inspection period (3–5 years). Table 2 presents the descriptions and scale used in the evaluation of the system’s condition.

The result of the inspection is recorded in the inspection report as E = needs to be repaired or K = acceptable condition. The inspection result of the ventilation system is E if the condition of one or more inspected items condition is not acceptable (Table 2). Items with recorded notes do not require re-inspection. The building owner is responsible for repairing ventilation faults without delay and for conducting a re-inspection. It is recommended that a re-inspection is conducted within six months of the previous inspection. The inspection result of the ventilation system is K after the approved inspection or approved re-inspection. The next inspection date is marked in the inspection report and should be conducted within three to five years, depending on the ventilation system.

Table 2. Criteria for condition of ventilation system.

Condition class/mark | Description of condition |

E | Condition not acceptable = Needs to be repaired · Critical design or operation documents missing · System or its component are defective and must be repaired or replaced · System or its component are dirty and prevent system from operating properly · System or its component must be cleaned The need for further investigation is added to the repair request by the letter L, if more detailed measurements are required. Any defects found must be rectified without delay. It is recommended that a re-inspection be carried out within six months of the initial inspection. |

H | Weak condition = Note · System component has failed or is about to fail, but does not significantly affect the functioning of the ventilation system · Number of people in the room is higher than the design value The notes recorded in the inspection report do not require re-inspection, but defects must be corrected without delay. Correction of defects recorded as a note are checked during the next periodic inspection. If the defects recorded as a note have not been rectified by the next periodic inspection, they are recorded in the inspection report as a correction request at the next inspection. |

K | Acceptable condition = Performs as intended The condition, functioning and cleanliness of the ventilation system are in an acceptable condition and will remain in order until the next inspection. |

The inspection is concluded at the final meeting, which is recommended to be held in connection with an approved inspection or an approved re-inspection. The final meeting is attended by the same people who attended the initial meeting. This meeting covers the results of the inspection and the remarks in the inspection report, which must be corrected without delay. The actions taken due to these remarks are checked in the next periodic inspection.

A certificate is drawn up for the approved inspection and is delivered in electronic form to the subscriber signed by the inspector. One copy of the certificate remains in the inspector's archives. The inspection certificate or information on the approved inspection should be available to the users of the building.

It is recommended that a ventilation system is inspected every three or five years. Complex and easily defective ventilation systems, such as variable air volume (VAV) systems, should be inspected every three years. Constant air volume (CAV) systems and exhaust ventilation systems should be inspected every five years. Natural ventilation systems should also be inspected every five years.

The ventilation inspector must be familiar with the legislation on ventilation and indoor air of buildings and the instructions and guides related to this legislation.

The inspector must be familiar with the most common equipment faults in CAV and VAV systems, mechanical exhaust ventilation systems and natural ventilation systems, and able to

· read and understand ventilation system drawings, control diagrams and operating reports

· evaluate the cleanliness of ventilation systems and their need to be cleaned using the visual cleanliness scale as a reference (LVI 39-10409)

· make a sensory evaluation of the adequacy /performance/air quality of the ventilation of the room, the balance of air flows and the room’s air distribution using detecting smoke or other methods

· reliably take differential pressure and temperature measurements

· identify the correct and incorrect functioning of ventilation and air conditioning systems as well as building automation systems

· evaluate the importance of regular ventilation maintenance for the condition, functioning and cleanliness of the ventilation system during the inspection interval

· rank the condition of the ventilation system according to Table 2 (E, H or K)

· evaluate the need for further investigation.

The ventilation inspection is performed by an inspector whose qualifications meet the competence requirements. Measurements must be made using meters and methods that are suitable for measuring pressure differences and temperatures. The instruments must be sufficiently accurate and have valid calibration. The cleanliness of the ventilation system is evaluated visually using the cleanliness scale as a reference. The content of the inspection report is standardized. The inspector must keep the inspection report and certificate for at least five years.

The walk-through inspection method was developed in the Inspection of ventilation system project. It is a simpler and faster method than that described in CEN / TR 16798-18. It is intended to be the first stage in evaluating the condition and functioning of ventilation systems and the need to clean them. Further examinations or measurements must be carried out, if the reasons for the poor operation or conditions of the ventilation system cannot be specified in the sensory inspection. A guideline on ventilation inspections has been published, and will be tested during the spring of 2022 in 10–15 municipal buildings in Southern Finland.

This article was written as part of the Inspection of ventilation system project funded by the Ministry of the Environment of Finland.

CEN/TR 16798-18. 2017. Energy performance of buildings. Ventilation for buildings. Part 18: Interpretation of the requirements in EN 16798-17. Guidelines for inspection of ventilation and air-conditioning systems (Modules M4-11, M5-11, M6-11, M7-11). Technical Report.

Boverket. 2021. The Swedish Obligatory Ventilation Control. Boverket – the Swedish National Board of Housing. Building and Planning. (In Swedish) https://www.boverket.se/sv/byggande/halsa-och-inomhusmiljo/ventilation/ovk/ (Accessed 25 January 2022).

Ekberg L. 2021. Inspection of ventilation system. REHVA Journal, 58 (2), 14-18.

EU. 2020. Final report - Technical study on the possible introduction of inspection of stand-alone ventilation systems in buildings. European Commission. 402 pages. https://op.europa.eu/en/publication-detail/-/publication/0bdd8b5e-b042-11ea-bb7a-01aa75ed71a1/language-en (Accessed 25 January 2022).

FINVAC. 2021. Inspection of ventilation system project. (In Finnish) https://finvac.org/iv-katselmukset/ (Accessed 25 January 2022).

LVI 39-10409. 2007. Ventilation system cleanliness check. Ventilation improvement and repair solutions. Rakennustietosäätiö RTS. 12 pages. (In Finnish).

ME 1009/2017. 2017. Decree of the Ministry of the Environment the indoor climate and ventilation of the new building. (In Finnish) https://www.finlex.fi/fi/laki/alkup/2017/20171009 (Accessed 25 January 2022).

Follow us on social media accounts to stay up to date with REHVA actualities

0