Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

The

suppliers of heat emitters have advertised and promoted positive individual

features of the product, like higher heat radiation, lower back wall losses and

quicker response to control. But this is not that simple: energy efficiency is

associated with the heating process and therefore the matter has to be seen in

the whole, not as a sub-optimization of the details.

There are

of course differences between different radiators and convectors, but the

question is, what are the differences in terms of comfort, energy efficiency

and in the end money?

The purpose

of this article is to provide answers to these essential questions with

objective measurement-based information.

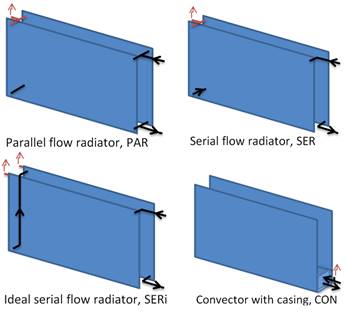

In Figure 1 the considered heat emitter types are illustrated.

Figure 1.

Investigated heat emitters: Normal 2-panel radiator with parallel flow (PAR),

typical 2-panel radiator with serial flow (SER), ideal 2-panel radiator with

serial flow (SERi), conventional round tube/lamella convector with or without

casing (CON) and ideal convector (CONi) like trench convector (not illustrated).![]() = Air bleed.

= Air bleed.

For

comparison of the heating process in buildings, following functions of heat

emitters are essential:

·

Human

response to the heat emission

·

Heat

radiation into the room

·

Back

wall heat losses

·

Temperature

control function

·

Heat

output capacity at partial loads

·

Influence

on heat generation

Secondary

and from the comparison perspective unimportant items like heat storage and

distribution (pipe work) losses as well as other control methods have not been

taken into consideration in this review.

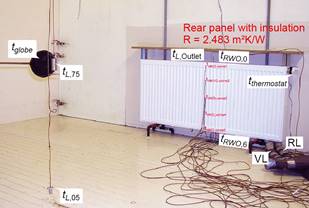

Main part

of the measurement results referred to in this article are from laboratory

tests performed by Dr. Konzelmann at the WTP GmbH Berlin (Figure 2) and from the analysis done by Professor Kurnitski and his team at the

Tallinn University of Technology as well as from our in-house analysis [1].

Figure 2.

Measurement set up at the WTP GmbH Berlin laboratory.

In

laboratory measurements, we wanted to find out how a normal 2-panel radiator

(PAR) and a typical 2-panel radiator with serial flow (SER) behave under the

control of a thermostatic radiator valve under comparable conditions.

Conclusions of the ideal 2-panel radiator with serial flow (SERi), conventional

convector (CON) and ideal convector (CONi) function can also be drawn with

sufficient accuracy from the measurement results.

Humans are to

detect small and rapid temperature variations in their environment. Up to 0.1

degrees step changes at operative temperature are measured in our own

experimental tests. Instead, slow temperature changes, less than one degree in

15 minutes [2], are not perceived, because the human body's own heat regulation

system is able to adapt to that change under normal conditions. This provides

an explanation why we do not experience a problem, when the thermostat

regulates the radiator water flow and the radiator temperatures shift

correspondingly.

The best

location of the radiator is beneath the window where it blocks the downdraught,

the convection flow from the cold window surface. Another important feature of

the radiator is its thermal radiation, which compensates for the radiant effect

of the colder window surface, creating the conditions for thermal comfort. In

fact, the radiator beneath the window extends the usable interior space.

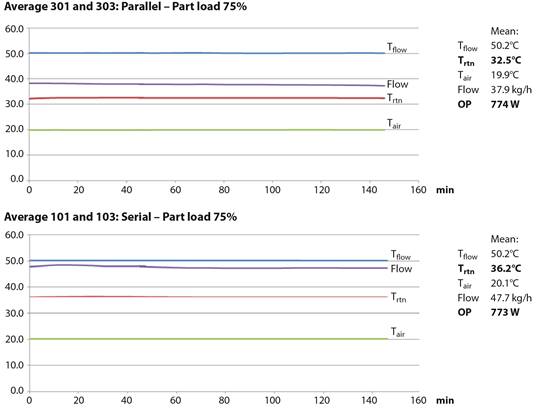

The 75%

part load means that the free heat gain rate is 25%. The free heat gains

consist of internal heat gains and solar radiation influence. The average cabin

cooling effect was 774 W. Flow temperature was set on 50°C. Thermostatic

radiator valve TRV was a conventional proportional one and water flow rate

lowered to a level of around 1/3 ṁN, where the PAR radiator heat output was in

balance with the heat demand. Differential pressure was kept constant in all

measurements. Nominal flow rate, ṁN, is the flow value of the radiator measured in

the EN 442 conditions and temperatures flow = 75°C, return = 65°C and air =

20°C.

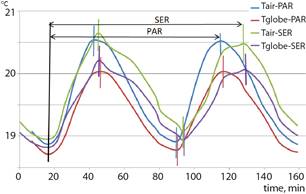

As shown in

Figure 3, The main observations of the test results are

that the SER had around 15% lower heat output capacity than PAR and resulting

to a 26% higher flow rate and to around 3.7°C higher return water temperature.

SER got also an average front panel temperature of 4.5°C higher and 2.5°C lower

average rear panel temperature than the PAR ones.

Figure 3.

PAR and SER running with TRV control at 75% part load conditions.

Theoretically,

the SERi heat output capacity could be a bit higher than SER although own

laboratory measurements of a commercial product did not confirm this difference

[1]. Obvious is that SERi gets at same conditions practically the same flow

rate and return temperatures as PAR. Due to the lower flow rate than SER at

these conditions the front and rear panel temperatures are slightly lower than

the SER ones. For comparison purposes (Table 1) we can well approximate the SERi

panel temperatures: the front 4.0°C higher than the PAR one and the rear

respectively 3.5°C lower than the PAR one. Convector features are handled in

the later part of this review.

Table 1.

75% part load measurement results. * Estimated value

Tflow = 50°C Tair = 20°C Фcool = 774 W | Trtn °C | Tfront °C | Trear °C |

PAR | 32.5 | 39.1 | 40.1 |

SER | 36.2 | 43.6 | 37.6 |

SERi | 32.5* | 43.1* | 36.6* |

CON | – | – | – |

CONi | – | – | – |

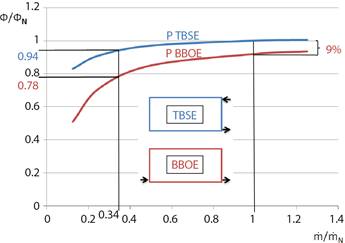

Panel

radiator heat output capacity depends not only on the temperatures, but also on

the flow rate and the pipe connection. Radiators with top-bottom-same-end (TBSE)

as well as top-bottom-opposite-ends (TBOE) connections are not so sensitive to

the water flow rate changes that bottom-bottom-opposite-end (BBOE) connections

are. This function is shown in the redrawn graph of Schlapmann [4], Figure 4. Here we can also see the reason why SER has a reduced heat capacity:

the SER rear panel is connected as BBOE and the heat capacity is clearly lowered

at smaller water flow rates. – Increased SER

radiator sizes are needed.

Figure 4.

Panel radiator heat capacity depends also on flow rate and connection type.

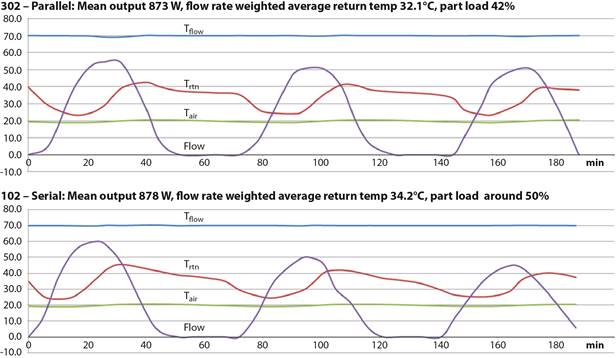

A 42% part

load means that the heat gains cover 58% of the heat demand. Measurements were

carried out with an average cabin cooling effect of 875 W and flow

temperature of 70°C in order to get well-measurable function values.

Thermostatic

radiator valve TRV starts to reduce the water flow to the level on which the

radiator heat output corresponds with the heat demand. The proportional control

is no longer reached and the control mode starts to fluctuate as on-off. Water

flow shut-off time is around 30% of the on-off cycle, however, with PAR a bit

longer than with SER.

At start

phase of the fluctuation both temperatures, air and globe, react a bit quicker

with PAR than with SER, due to the higher output capacity of PAR, Figure 5. However, this difference equalizes due to the fact that TRV determines the pace: During regular fluctuation both radiators PAR

and SER have the same cycle time, Figure 6. And that is why there are no

practical differences in the controllability of radiators. Convectors may

benefit slightly from the reduced output capacity at high heat gain rates and

the shut-off time can be shorter. This feature is described in the chapter Return water temperature influence.

Due to the

insufficient differences at on-off modes, the temperature fluctuation impact on

the energy use has not been taken into consideration in this article (generally

it depends on the control used).

Figure 5.

PAR heats up the room slightly quicker than SER.

Figure 6.

PAR and SER running with TRV control at 42% part load conditions. On-off-mode.

Water flows

fluctuate between 0 and 60 kg/h. Flow-rate-weighted average return

temperatures of SER were 2.1°C higher than the PAR ones. Front panel mean

temperature of SER was 5.3°C higher than PAR. Rear panel mean temperature was

correspondingly 3.2°C lower for SER.

Condition

for a PAR (radiator type 22-600-1400), where Tflow = 70°C and Trtn = 32°C with continuous flow, in

other words TRV is still in proportional mode, corresponds to the heat gain

rate of 35%. Obviously the TRV can modulate the flow up to this 35% heat gain

rate and at higher heat gains the TRV changes over to on-off operation.

Corresponding SER values and estimated SERi values are shown in Table 2.

Table 2. 42%

part load results.*Estimated value

Tflow= 70°C Tair= 20°C Фcool = 875 W | Weighted Trtn °C | Tfront °C | Trear °C |

PAR | 32.1 | 40.3 | 40.7 |

SER | 34.2 | 45.6 | 37.5 |

SERi | 32.1* | 45.1* | 36.5* |

CON | – | – | – |

CONi | – | – | – |

For

comparison purposes two different building types have been selected, old and

norm: A post WWII building without thermal insulations layers in the walls, but

2-glass-windows and a norm building representing both newer building types,

from the 90s, and renovated older buildings. Old and norm building features

displayed in Table 3 have been used for calculations.

Table 3.

U-values of reference buildings

External

wall U-value | Window

U-value | |

Old building | 1.39 W/m²K | 2.8 Wm²K |

Norm building | 0.27 W/m²K | 1.2 W/m²K |

Climate

conditions are taken according to Dresden (Germany), where the design outdoor

temperature is -15°C.

Outdoor

temperature of 0°C has been chosen as reference, because it is reasonably near

to the mean temperature of the heating season.

Reference

room is 16 m², window 1.4 x 1.5 m² and heat emitter size 1.4 x 0.6 m².

Heating system design temperatures are 70/55/21°C for old building and 55/45/21°C

for norm building. System flow temperatures at Tout= 0°C are in old building 50°C and in norm

building 41°C. Air change rate is 1/h in both cases. Full load heat demands are

in the old building 890 W and in the norm building 420 W. Heat gain

rates are at these conditions in old building 25% and in norm building 35%.

Default is that at both conditions the TRV works in proportional flow mode.

These

conditions are chosen in order to show the maximum differences between the

heaters. However, in practice the differences are smaller.

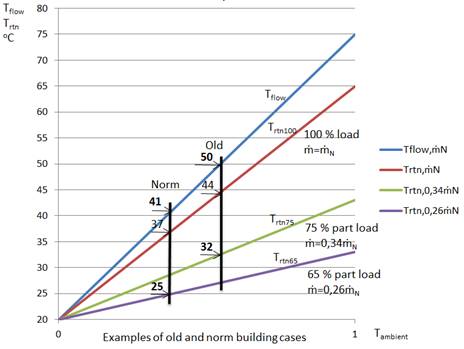

With help

of the conversion graph in Figure 7, based on the measured

temperatures, it is possible to estimate the average panel temperatures from

the flow and return temperatures of radiator (Table 4

and 5).

Figure 7.

Radiator temperatures of PAR and SERi in relation to the flow temperature and

the part load rate.

Table 4.

Radiator surface temperatures, old building. *Selected value

Old

building | PAR | SER | SERi | CON | CONi |

Front panel mean, °C | 39.1 | 43.6 | 43.1 | 31* | – |

Rear panel mean, °C | 40.1 | 37.5 | 36.6 | 31* | – |

Table 5.

Radiator surface temperatures, norm building. *Selected value

Norm

building | PAR | SER | SERi | CON | CONi |

Front panel mean, °C | 28.0 | 31.0 | 29.8 | 25* | – |

Rear panel mean, °C | 28.2 | 27.0 | 26.5 | 25* | – |

Based on

these average front panel temperatures it is possible to calculate the heat

radiation influence according to ISO 7726 standard. Measurement point is in the

middle of the room at 0.6 m above floor level, referring to a person in a

sitting position. These calculations are made by Equa Simulation Finland Oy [5].

There is no

standardized calculation method for energy estimations, but the following

calculation method, mean operative temperature MOT, is commonly used. In Tables 6

and 7are the calculated air temperatures giving the same operative

temperatures of 21°C at different heat emitter cases. SER shows the lowest air

temperature due to the highest radiation and CONi respectively the highest.

SERi is quite similar as SER.

Table 6.

Air temperatures giving the same 21°C MOT, old building.

Old

building | PAR | SER | SERi | CON | CONi |

Air, °C | 21.38 | 21.26 | 21.27 | 21.59 | 21.90 |

Table 7.

Air temperatures giving the same 21°C MOT, norm building.

Norm

building | PAR | SER | SERi | CON | CONi |

Air, °C | 21.14 | 21.05 | 21.06 | 21.21 | 21.32 |

Reference location

Dresden’s design outdoor temperature for heating is -15°C. Climate data for the

calculations is taken from the Weather Underground.

Degree-day

value of the old building with base temperature 17°C is 2902 and the difference

of one degree corresponds with 10% difference in energy use.

Norm

building degree-day value with base temperature 15°C is 2354 and the difference

of one degree corresponds with 12% difference in energy use.

Tables 8 and 9 show how much operative temperature

differences (Tables 6 and 7) add to energy needs of different

emitter types.

Table 8.

Heat radiation influence in old building.

Old

building | SER/SERi | PAR | CON | CONi |

Additional energy | 0 | + 1.2% | + 3.3% | + 6.4% |

Table 9.

Heat radiation influence in norm building.

Norm

building | SER/SERi | PAR | CON | CONi |

Additional energy | 0 | + 1.0% | + 1.8% | + 3.1% |

From the

measurement results of WTP GmbH Berlin it is possible to calculate, with good degree

of accuracy, the back wall heat losses caused by the heat emitter, see Table 10, 11 and 12.

Table 10.

Emitter back and back wall temperatures in old building. *Selected value

Old

building | PAR | SER | SERi | CON | CONi |

Emitter back mean, °C | 40.1 | 37.5 | 36.6 | 31* | – |

Back wall mean, °C | 29.5 | 28.1 | 27.6 | 24.7 | – |

Table 11.

Emitter back and back wall temperatures in norm building.*Selected

value

Norm

building | PAR | SER | SERi | CON | CONi |

Emitter back mean, °C | 28.2 | 27.0 | 26.5 | 25* | – |

Back wall mean, °C | 23.3 | 22.6 | 22.4 | 21.6 | – |

Following the

back wall temperature values the radiator back wall losses can be calculated at

outdoor temperature of 0°C.

Table 12.

Back wall losses caused by the heat emitter.

Additional

energy need | PAR | SER | SERi | CON | CONi |

Old building | + 2.24% | + 1.91% | + 1.79% | + 1.10% | – |

Norm building | + 0.36% | + 0.28% | + 0.26% | + 0.18% | – |

Bleeding of

the air is a problem at construction of the serial panel radiators. In order to

get the serial panel radiator to function ideally, both panels, front and rear,

should be bled separately. To enable this, complicated air venting arrangements

are needed. Therefore, the product costs will increase.

All

commercial SER products are compromised by having a tiny opening between the

front and rear panels. This helps to bleed the air through the same air vent at

the upper end of the radiator, but it inevitably leads to a leak flow from front

panel to rear panel resulting in a situation, where the top of the rear panel

is warmer than the flow water from the front to back panel. This prevents the

water rising up in the rear panel, which causes an additional reduction on the

output capacity of the rear panel particularly at the part load conditions.

This has been found in the measurements [3].

The leak

flow in SERi radiator reduces also the output capacity and equalizes the front

and rear panel temperatures. However, the disadvantage is not as serious as in

SER radiators.

Serial

panel radiator has an increased flow resistance. When parallel panel radiator

resistance corresponds with around kv 3.3, serial panel resistance is more

than the double, kv 1.3. The pressure difference between the panels can be

a few hundred Pascal even in normal sizes of serial radiators and the leak flow

through even smaller openings is unavoidable.

As shown in

Figure 4 panel radiator output capacity depends also on

the connection type and flow rate. We can recognize that SER radiator’s rear

panel connection is BBOE type and thereby SER radiator capacity is always

smaller than the PAR one. In addition, the leak flow reduces the output

capacity further.

As

mentioned above in the 75% part load case, the return water temperature of SER

radiator was measured 3.7°C higher than in the PAR. Also, in the 42% part load

case this reduction was remarkable – the higher return water temperature,

the higher the condensing boiler and heat pump fuel consumption.

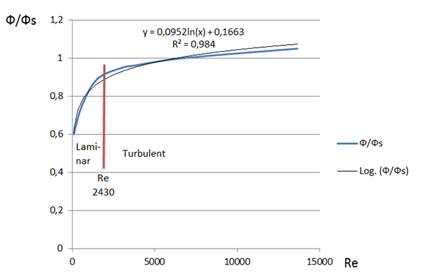

Heat output

capacity of convectors with round pipe/lamella construction depends strongly on

the water flow type, turbulent or laminar. When the flow rate is decreased, the

convector output capacity decreases in accordance with the Reynolds number.

This dependence, according to Dr. Konzelmann [3], is shown in Figure 8.

Figure 8.

Convector heat output depends on water flow conditions.

Example: Typical

convector construction with heat output capacity at dT50K (EN442) is 800 W.

In case of 75% part load, flow temperature of 50°C and 248 W heat demand

the return water temperature rises up to a level of 39°C. – Comparable case, PAR radiator with a return water

temperature of 33°C. |

Note. This heat output capacity reduction effect has

not been taken into account in the product standards EN442 and EN16430:

standard heat output values are valid only at full load conditions with

relatively high water flow rates. Design flow rates are often clearly lower,

which leads to incorrect design selections.

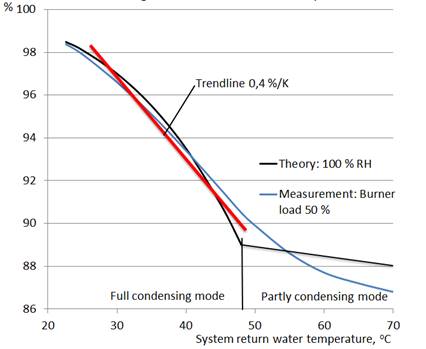

In Figure 9 we can find, according to Professor Oschatz’s measurement and study

[6], the dependence of heating system return water temperature on the condensing

gas boiler combustion efficiency: trend line value 0.4%/K. The burner load rate

has also a slight influence on the efficiency: the lower load the higher

efficiency and respectively the higher load the lower efficiency.

Figure 9.

Condensing boiler combustion efficiency depends on system return water

temperature

Annual

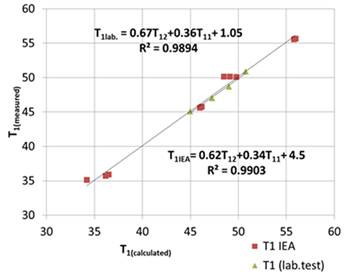

coefficient of performance, COPa, is also linked not only to the system flow

water temperature, as often assumed, but also to the system return water

temperature. According to the calculations done the change of one degree in

system water temperature gives a COPa change of 1.2% [8]. In addition, the COP

value depends on the heat pump condenser temperature. It is also measured that

the system flow water temperature has a 2/3 and system return water temperature

a 1/3 influence to the condenser temperature, Figure 10.

Figure 10.

Influence to heat pump efficiency, Prof. Kurnitski [7]. Flow water temperature

2/3 and return water temperature 1/3.

In

conclusion, we can say that in both condensing boiler and heat pump, lowering

the system return water temperature by one degree, the heat generation

efficiency rises by 0.4%.

When using

the return water temperatures from the 75% par load case, SER has 3.7°C higher

return water temperature than PAR and SERi, and CON and CONi respectively

around 6°C higher than PAR and SERi, following figures for heat generation efficiencies can be calculated, Table 13. These values are valid for both reference buildings with a reasonable

accuracy.

Table 13.

Relative heat generation influence and additional energy needs.

Heat

generation influence | PAR/SERi | SER | CON/CONi |

Additional energy | 0 | + 1.5% | + 2.4% |

Table 14 shows a collection and summary of

the relative effect of different heat emitters on the heating system

efficiency: additional energy need.

Table 14.

Relative effect of different heat emitters on system efficiency

Additional

energy need | PAR | SER | SERi | CON | CONi |

Old building | + 3.4% | + 3.4% | + 1.8% | + 6.8% | + 8.8% |

Norm building | + 1.4% | + 1.8% | + 0.3% | + 4.4% | + 5.5% |

According

to the results differences between the radiators in both old and norm buildings

are very small, max 1.5%. However, the convectors differ clearly from the

radiators.

Heat

radiation differences of different radiator types are so small that they are

practically out of human perception capability [9].

When the

functional differences between the radiators are small, the decisive difference

is their price. But how much more money is meaningful to invest in radiators

that are claimed to be more energy-efficient?

Example: In

a typical German detached house of 170 m² from the mid-90s the space

heating energy is around 15 000 kWh per year. When using the gas

price of 0.065 €/kWh, the heating bill is around 975 €/a. The result

difference between a “standard radiator” and an “ideal serial panel radiator”

is 1.1%. The corresponding energy cost difference is on average 10.70 €/a.

This divided typically into 10 radiators results in maximum annual savings of 1.07 €

per radiator. For instance, the price of an “ideal

serial panel radiator” for the end user is several dozens of euros higher than the price of a

standard radiator. This extra price, for example 30 € for the end user, divided by 1.07 €/a

leads to a pay-back time of 28 years!

The reduced

heat output capacity of the “typical serial panel

radiator”

causes needs to increase the radiator size: for example, a typical 10% addition

increases the price for the end user by around 25 €, and this without any pay-back.

The

additional heating energy demand and the lack of radiant effect of convectors

seem to be more noticeable: there must be additional arguments for convector

selection.

In modern

energy efficient buildings, which are better insulated and often equipped with

heat recovery ventilation, the heating energy demand is only half or less of

the “norm building” used in this review. Therefore, the small differences of

radiators in new buildings are completely irrelevant from the energy saving

point of view.

In

conclusion, it is clear that there is no tangible, financial nor physiological

benefit for home owners to pay the increased cost associated with the alleged

but unsubstantiated “more energy efficient radiators”. – A standard radiator is the best option.

[1] RETTIG ICC Research Centre, EN442 laboratory.

[2] ASHRAE ANSI standard 55.

[3] WTP GmbH Berlin, EN 442 laboratory.

[4] Schlapmann, HLH 9-76.

[5] Equa Simulation Finland Oy.

[6] Technical University of Dresden.

[7] Tallinn University of Technology.

[8] IVT VPW2100 software.

[9] Human Thermal Model, VTT Technical Research

Centre of Finland.

Follow us on social media accounts to stay up to date with REHVA actualities

0