Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

Daniel Olsson¹ | Lars Ekberg¹,² | Mats Persson³ |

¹ CIT Energy Management AB, Gothenburg, Sweden² Architecture and Civil Engineering, Chalmers University of Technology, Sweden³ Department of Materials Science and Applied Mathematics, Malmö University, SwedenE-mail : lars.ekberg@chalmersindustriteknik.se | ||

The second edition of a knowledge review/compilation commissioned by the Swedish National Board of Housing, Building and Planning was published early 2022 [1]. The compilation comprises:

· Ventilation state of the art

· Legislation & guidelines

· Measurement & verification

· Energy requirements – Eco design

· Fire protection

· Disease transmission prevention

· Mapping of actors/stakeholders

The purpose of this endeavor is to map Swedish stakeholders related to ventilation; industry, real-estate, consultants, other organizations, academy, authorities etc. As a part, a questionnaire survey was conducted broadly among these stakeholders.

The aim was to identify important issues and problem areas related to ventilation, as perceived by the various stake-holders. The intention is to provide a broad and accurate understanding of the needs of development in areas related to ventilation.

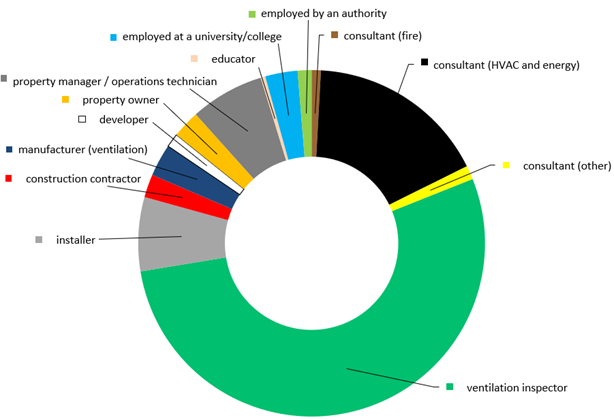

A large number of different actors were invited to answer a questionnaire prepared. All in all, the survey was answered by 215 people, of whom 55% were professionals within ventilation inspection, 16% were different types of consultants and the remaining 29% consisted of a total of nine different occupational categories.

Figure 1. Distribution of the respondents’ main professional roles.

The web-based survey was divided into six sub-areas:

1. Identification of the respondent’s professional role and experience in ventilation issues

2. The respondent’s general experience regarding ventilation

3. Questions regarding ventilation-related complaints from occupants

4. Identification of ventilation-related problems

5. Measures against ventilation-related problems

6. Questions regarding energy efficiency

For each area, a number of claims of the type “Insufficient airflows in apartment buildings often turn out to be due to...”, followed by a number of response options. For each answer option, the respondent was asked to indicate, using a seven-point scale, the extent to which they agreed with the response options. Furthermore, it was always given the opportunity to comment in free text and/or reply “do not know”.

Below are a number of general observations highlighted for some of the questions. A more complete account of the survey responses and the different occupational categories can be found in [2].

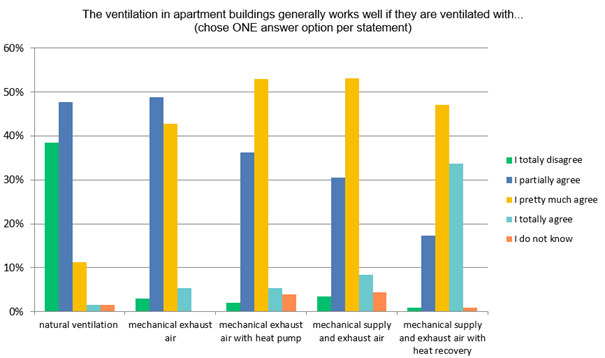

· Natural ventilation was typically claimed to perform worse than mechanical ventilation systems, often due to insufficient supply opening areas (See Figure 2)

· Mechanical exhaust and supply usually perform well, but are sensitive to poor balancing.

· Ventilation-related complaints often deal with draft, odor from cooking and “stuffy” air.

· Air quality problems in non-residential buildings are often due to changes in the use of the building without implementation of the ventilation adaptations necessary.

· Maintenance and periodic checks are main keys to well-functioning ventilation.

· There are only small possibilities to increase ventilation with existing ventilation systems.

· Schools and preschools in particular have often too low ventilation capacity (under-sized systems).

· Demand-controlled ventilation is claimed to work best when controlled with respect to both room temperature and CO₂-concentration.

· Filters are usually changed according to schedule (not taking into account the filter’s pressure drop).

· There are often opportunities to make economically profitable energy saving measures related to ventilation.

· Re-circulation of extract air is generally perceived as a poor option, except in industrial and warehouse premises.

Figure 2. Distribution of the respondents’ attitude to the function of different ventilation systems in apartment buildings.

Some of the respondents pointed out that several of the questions were too “narrow” for a justified answer. Indeed, it can be perceived as too generalizing to rank different ventilation principles (natural, mechanical exhaust, mechanical exhaust and supply etc.) in terms of how well they usually work. The fundamental idea emerged that different system solutions have different pros and cons. The important thing is not what type of system is chosen. Instead, the important thing is that the solution chosen mustbe designed taking into account the conditions defined by the building and the operation. For example, a well-designed mechanical exhaust system can work better than a poorly designed system with mechanical supply and exhaust.

Each system must be designed in order to facilitate efficient inspections and service. Several respondents pointed out in this context that it is a particularly big challenge to inspect modern systems for demand-controlled ventilation. An important question is which aspects should be included in the inspections. In addition to measuring airflows, more checkpoints may be required to verify the more or less complex control functions. Another question is how to ensure that the checks are carried out under realistic/real conditions.

Overall, the survey responses indicate that ventilation malfunctions and deficiencies are revealed roughly to an equal extent through the mandatory ventilation inspections – the OVK-inspections [3] and through complaints from the building users. This is followed by alarms from the building automation system and from visual operational status inspections. This outcome indicates that many respondents see great value in the mandatory OKV-inspections, but that there is a great need for improvements. In an ideal situation, no deficiencies should be identified by complaining tenants. According to the survey responses, the way to get there can be through an improved system for mandatory ventilation inspections together with better utilization of building automation and monitoring and regular operational follow-up.

Several respondents point out that the ventilation flows are too often chosen to meet the authorities’ minimum requirements, without regard to the actual pollution generation from the building itself, the people and the activities in the building. Today, these minimum flows are selected by default and provided that neither operations nor construction equipment emit much pollution. If we instead should really be able to determine the required air flow rate, taking into account the real need from a hygienic point of view, it will be necessary to utilize quality-assured data on the source strength of all relevant sources of pollution. However, such data are generally not available to the building sector.

It must be acknowledged that the standard EN 16798-1:2019 offers a methodology to classify building products with respect to the potential release of pollutants to the air - and to consider this aspect when searching for the dimensioning ventilation rates. At least in Sweden, this way of working has not yet come to use in practice. It might be easy to classify materials such as glass, stone and metal as low-emitting. It is way harder to find useful data on the rate of pollutant emissions from other materials. Once such data become available, it might be possible to determine the required airflow rate in order to dilute emissions to acceptable levels. However, for many substances the question remains regarding the acceptable concentration level.

Several respondents pointed to a need for increased competence in the building sector. It is not just a question of the need for each professional to have sufficient knowledge within their own trade, but about the need to have sufficient understanding of the whole. At least the understanding needs to be sufficient for each professional group to be able to communicate within their own group and with adjacent specialist areas. For example, a ventilation technician needs to have a basic understanding of control and control technology and vice versa; the control specialist needs basic understanding of ventilation technology. Perhaps somewhat surprisingly, this is rarely the case. Basically, it is a question of enduring a holistic approach in a broad sense. It is about everyone applying their own solid knowledge and contributing to wise decisions by communicating effectively. This affects everyone who in one way or another contributes to the creation and maintenance of well-functioning ventilation systems in energy-efficient buildings with a good indoor climate.

Ekberg L, Fagergren T, Hjelmer P-E, Kempe P, Ruud S, Persson M (2022) Ventilation i Sverige – En kunskapssammanställninghttps://blogg.mah.se/bygglearn/files/2022/02/VentilationSverige.pdf.

Ekberg L, Olsson D, Persson M (2022) Ventilation i Sverige 2021 – Enkät https://blogg.mah.se/bygglearn/files/2022/01/Kartla%CC%88ggningVentilation-enka%CC%88t.pdf.

Boverket (2021) The Swedish Obligatory Ventilation Control. Boverket – the Swedish National Board of Housing, Building and Planning. https://www.boverket.se/en/start/building-in-sweden/swedish-market/laws-and-regulations/national-regulations/obligatory-ventilation-control/.

Follow us on social media accounts to stay up to date with REHVA actualities

0