Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

Energy

labelling enables customers to make informed choices based on the energy

consumption of energy-related products. This entails several benefits: reduces

energy demand and saves customers money on energy bills, contributes to

innovation and investment in energy efficiency, and supports industries which

develop and produce the most energy efficient products.

However, a

lack of ambitious requirements and standardised/reliable data for heating and

cooling technologies will lead to a risk that the cost effective and energy

saving potential will not be fully utilized and that the consumers will lose

their confidence in the energy labelling and other product information

provided by suppliers.

The

technologies considered in this study are: air conditioners, liquid chilling

packages and hydronic heat pumps, rooftop and variable refrigerant flow units.

Comfort air

conditioners (ACs) consist of a reversible heat pump that can be used for both

heating and cooling the air in a room. This type of heating and cooling

technology has gained increasing market penetration in recent years and thus,

it has been included in the ecodesign (2009/125/EC) and

energy labelling (2010/30/EU) European directives (implemented through

regulations No 206/2012 and No 626/2011) to contribute with a large amount of

energy savings in the European Union within the next 10 to 20 years. The

products evaluated in this work have a capacity that varies between 2 kW

and 15 kW [1].

Liquid

chilling packages and hydronic heat pumps (LCP-HP) consist in electrically

driven reversible heat pumps used for heating and refrigeration. Like air

conditioners, LCP- HP units may be air-cooled or liquid cooled, but instead of

heating and/or cooling air, they transfer heat to liquid water. The units

considered in this work have a capacity up to 1500 kW (water-cooled) and

600 kW (air-cooled) [2].

Rooftop

(RT) units consist of a blower, heating or cooling elements, filter racks or

chambers, sound attenuators and dampers. They are used to condition and

circulate air as part of a heating, ventilation and air condition (HVAC)

system. Rooftops are designed for outdoor use, as it names indicates, typically

the roof. The units considered in this work have a rated capacity up to 200 kW

[3]. They can be air-to-air or water-to-air rooftop units.

Finally,

variable flow refrigerant (VFR) units is a more recent HVAC technology (1982).

A typical unit consist of one or several outdoor units – with the compressor

and condenser, several indoor units –evaporator, refrigerant piping running

between the outdoor and indoor units. These types of systems modulate the flow

of refrigerant according to exact demands of one or several areas and are

especially suited for large buildings with several rooms – commercial

buildings, offices, schools, etc. In this study, only single module outdoor

units used for cooling-only, heating-only and reversible units are considered.

They can be air- or water- sourced. The units considered in this work have a

rated capacity between 7.2 and 61.6 kW [4].

To assess

the energy efficiency progress in heating and cooling European market,

statistical analyses were made on reliable performance rating data of an

independent database over a period of three years. The data studied is

third-party certified, i.e. it proceeds from tests run at independent

laboratories. The rating data studied includes:

·

Coefficient

of Performance (COP) and Energy Efficiency Ratio (EER): For all systems

considered in this study the COP – energy efficiency in heating mode – and EER

– energy efficiency in cooling mode – are defined as the ratio between the

thermal energy delivered and electrical power absorbed by the unit at reference

design conditions [1; 2; 3; 4].

·

Seasonal

Coefficient of Performance (SCOP) and Seasonal Energy Efficiency Ratio (SEER):

The calculation of SCOP and SEER is in accordance with EN14511:2013,

EN14825:2013 and the [6].

·

Energy

classes:

o AC: The energy classification for air conditioners is defined in the European Commision Regulation (EU) No 626/2011 supplementing the Directive 2010/30/EU [5]. See Annexes Table 7.

o LCP-HP: The energy classification for LCP-HP is defined in the Eurovent Certita Certification Rating Standard [2].

o RT: The energy classification for RT systems is defined in the Eurovent Certita Certification Rating Standard [3].

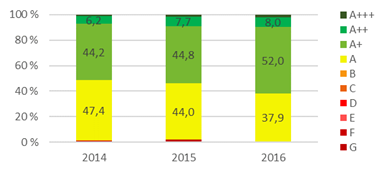

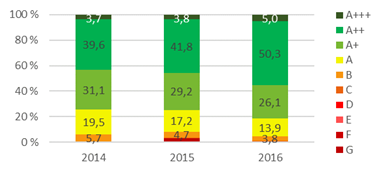

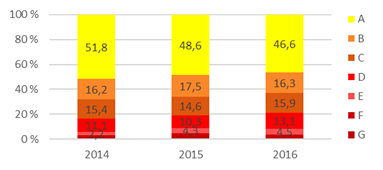

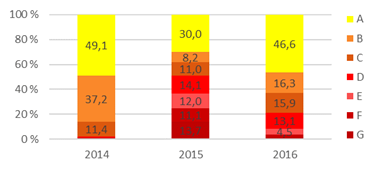

Figure 1 and Figure 2 reflect the effects of the entry

into force of the ecodesign regulation requirements illustrated by the

evolution of energy classes (introduced in Jan.2013 for AC units). Non-ducted

AC units are classified with 10 different energy classes, from the best, A+++,

to the worse, G. This sample includes more than 6500 AC units between the years

2014 and 2016. The share of non-ducted

AC units with high energy efficiencies (classes A+, A++ and A+++) is

larger than 50% and has smoothly increased along the years in both heating (Figure 1) and cooling mode (Figure 2). There are no units in the market

labelled with classes lower than D.

The

progress illustrated in Figure 1 and Figure 2 mirrors the positive effects of the

regulations. However, in the recent revision of the European Commission of the

Energy Labelling directive (2010/30/EU) [7] it was identified the need to

update the energy labelling framework to improve its effectiveness. Customers

compare labels across different product groups (for example, between ACs and

dishwashers), and not all have the same number of classes, i.e. some vary from

A to G (7 classes) while others vary from class A+++ to class G (10 classes,

case of AC units). This leads to some confusion making some customers believe

that more efficient products could exist or, in the opposite case, that a class

A product in a product group where classes vary, from A+++ to G, is very

efficient. In the new revision, the Commission considers that the

classification using letters from A to G has shown to be more effective for customers

and intends to uniform this across products groups (except space and water

heaters). For all other products, all class A+++ will be assigned class A,

class A++ will be class B and so forth from Jan. 2019 [8].

Figure 1. Seasonal Cooling Energy Efficiency – seasonal energy efficiency ratio (SEER) transformation of non-ducted AC units between 2014 and 2016.

Figure 2. Seasonal Heating Energy Efficiency – seasonal

coefficient of performance (SCOP) transformation of non-ducted AC units between

2014 and 2016.

Today, the

energy class of AC units is determined through the calculation of the seasonal

energy efficiency ratio (SEER) and seasonal coefficient of performance (SCOP)

of the unit. Compared to the previous requirements, before 2013, based on the

energy efficiency ratio (EER) and the coefficient of performance (COP) a single

standard operation condition, the SCOP and SEER are calculated based on

measurements at six different ambient conditions (known as points A, B, C, D, E

and F). They represent the fluctuating demand in residential buildings.

Additionally, the new method takes into account the residual electric energy

demand during standby and off-mode periods. Altogether, this gives a more

realistic picture of the phase of use of AC for consumers.

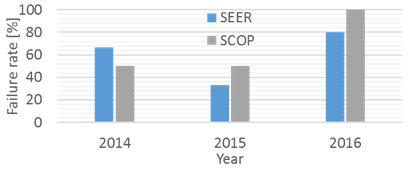

The

regulations demand the manufacturers to self-declare the performance data.

These new requirements and its complexity stimulate manufacturers to be more

knowledgeable about their products and discourages free-riders. Yet, empirical

data from the last three years show that not all manufacturers are able to

declare accurate performances (Figure 3). When compared to its performance

data tested in independent labs, the share of non-conform declared ratings was

above 30% and has significantly increased. This mismatch between declared and

tested values will over and above have a negative impact on the confidence of

end-use consumers and investors in this technology and certainly, jeopardize

its potential to reduce energy demand and increase the energy efficiency in

buildings. This emphasizes the importance of third party independent testing

performed by market surveillance authorities and independent certification

organisations. These organisations and their activity ensure the reliability of

values declared and thus, promote energy efficiency and end-user confidence.

Figure 3. Failure rate of tested non-ducted AC units in the period 2014-2016

according to Eurovent Certita Certification testing campaigns.

Since

January 2013, the EU regulation No 206/2012 requires minimum levels of energy

efficiency and sound power for all electric AC units with a rated capacity up

to 12 kW for cooling or heating (if the unit has no cooling function). The

minimum requirements depend on the rated capacity (<6 kW and 6-12 kW)

and, since January 2014, also on the global warming potential (GWP) of the

refrigerant (GWP > 150 or GWP ≤ 150), the working

fluid of the unit.

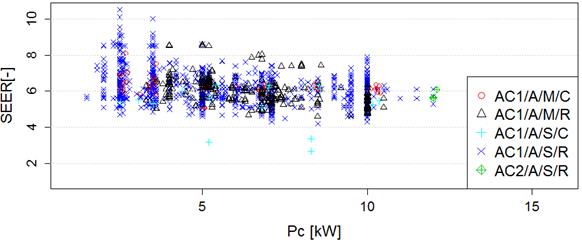

Figure 4shows the SCOP values of the products analysed in this study. All units

seem to comply with the ecodesign minimum (SCOP ≥ 3.8) [5]. The

units with larger

capacity (>12 kW) have SCOP values less spread than smaller capacities

units. Together with this, it is evident that smaller capacity units can reach

SCOP values much higher (max. = 6.2) than the minimum requirements imposed

today.

Figure 4. SCOP values dispersion for each of

the non-ducted AC unit type according to its rated heating capacity (Ph). See Table 6 in Annexes for unit type.

Nonetheless,

it is should be highlighted that the average SCOP has evolved in a very

conservative way during the last three years. Table 1 outlines the SCOP transformation of

non-ducted AC units between 2014 and 2016. The Split Reversible units (…/S/R)

represent the greatest progress with maximum of 0.96% SCOP increase between

2015 and 2016. Together with the high SCOP values, the facts suggest that a

readjustment of the minimum requirements of the current regulation is

recommended in the future. Rated capacities of AC units with a cooling capacity

larger than 12 kW (AC2 in Figure 4) are plotted to exemplify what can

be expected from larger units. It seems that their seasonal energy efficiency

in heating mode is analogous to AC1 units.

Table 1. Summary of average and std. deviation SCOP values for each non-ducted

AC unit type.

Unit

Type | SCOP Mean (x̄) | SCOP Std. deviation (s) | Δ | Δ | ||||

Year | 2014 | 2015 | 2016 | 2014 | 2015 | 2016 | ||

AC1/A/M/R | 3.96 | 3.97 | 4.00 | 0.24 | 0.22 | 0.23 | +0.25 | +0.76 |

AC1/A/S/R | 4.04 | 4.06 | 4.10 | 0.30 | 0.32 | 0.32 | +0.46 | +0.96 |

AC2/A/S/R | – | – | 4.01 | – | – | 0.01 | – | – |

Figure 5 shows the SEER values of the

products analysed in this study. As it happens for SCOP, the larger

capacity (>12 kW) units have SCOP values less spread than units with

smaller capacities.

Figure 5. SEER values dispersion for each of the non-ducted AC unit type

according to its rated cooling capacity (Pc). See Table 6 in Annexes for unit type.

Table 2 outlines the SEER transformation of

non-ducted AC units between 2014 and 2016. The SEER has evolved in an

indisputable way for both split (…/S/R) and multisplit reversible (…/M/R)

units. Given the existence of high SEER values, the question of the

suitableness of the minimum requirements pops-up once more. In distinction to

reversible units (…/R), the only cooling mode (…/C) units exhibit a

deterioration of the seasonal energy efficiency ratio. Some of only cooling

units have tested rated capacities below the EU minimum requirements

(SEER≥4.3) [5]. This might be caused by the decreasing interest in units

that only deliver cooling in buildings applications and therefore,

manufacturers abandon their development.

Table 2. Summary of average and std. deviation SEER values for each non-ducted

AC unit type.

Unit

Type | SCOP Mean(x̄) | SCOP Std. deviation (s) | Δ | Δ | ||||

Year | 2014 | 2015 | 2016 | 2014 | 2015 | 2016 | ||

AC1/A/M/C | – | 6.36 | 6.27 | – | 0.66 | 0.41 | – | -1.42 |

AC1/A/M/R | 5.85 | 5.88 | 6.18 | 0.51 | 0.51 | 0.86 | +0.51 | +5.10 |

AC1/A/S/C | 5.43 | 5.19 | 5.10 | 0.95 | 1.20 | 1.35 | -4.42 | -1.73 |

AC1/A/S/R | 6.08 | 6.12 | 6.24 | 0.87 | 0.90 | 0.91 | +0.66 | +1.96 |

AC2/A/S/R | – | – | 5.92 | – | – | 0.24 | – | – |

Finally,

under the ecodesign requirements a bonus is proposed to guide the market in the

direction of the use of refrigerants with low global warming potential (GWP)

falls short of expectation. The bonus consists in imposing lower minimum energy

efficiency for AC units using low-GWP refrigerants (GWP < 150).

The introduction of low GWP refrigerants represents certain technological

challenges with respect to energy efficiency of AC units due to thermodynamic

characteristics of new refrigerants but great benefits in terms of reduction of

global warming gas emissions, in the case of leakage. According to this study (Figure 6) among over 6500 non-ducted AC

products, low-GWP are not present in the market. The R410A refrigerant (GWP = 2088)

is by far the dominating refrigerant used in the market of AC units in Europe

while R32 (GWP = 675) has been gaining moderate importance. Perhaps,

more stringent ecodesign minimum requirements for AC units using conventional

refrigerants could also steer the market for the use of low GWP refrigerants.

Figure 6. Evolution of refrigerants used in non-ducted AC units.

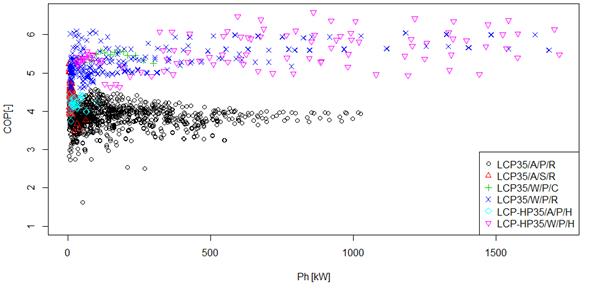

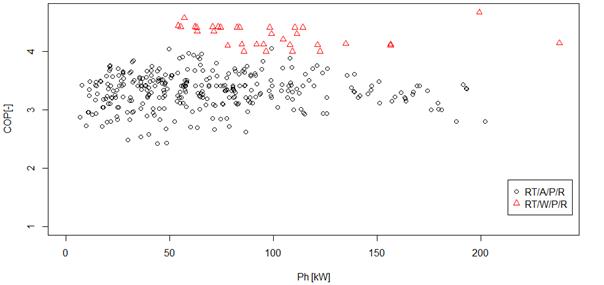

The COP of

LCP-HP units in low temperature heating mode sorted by unit type are plotted

against its capacity in Figure 7. Air source packaged reversible

units (LCP35/A/P/R) tend to perform worse than any type of unit. Otherwise, the

COP values of LCP-HP units seem to exhibit no significant statistical dependence

between energy efficiency (COP) and its capacity.

The maximum

average COP among LCP-HP units in low temperature (35°C) heating mode was 5.59

– in water based packaged (LCP-HP35/W/P/C) units, while the minimum was 3.89 in

air based packaged reversible units (LCP-HP35/A/P/R). See Table 3.

Table 3. Summary of average and std. deviation COP and EER values for each

LCP-HP unit type.

Unit Type | COP | COP Std. | EER | EER Std. |

LCP35/A/P/R | 3.89 | 0.28 | 3.43 | 0.42 |

LCP35/A/S/R | 4.34 | 0.31 | 3.38 | 0.33 |

LCP35/W/P/C | 5.43 | 0.11 | 3.58 | 0.47 |

LCP35/W/P/R | 5.32 | 0.35 | 6.80 | 0.80 |

LCP-HP35/A/P/H | 4.21 | 0.16 | 5.64 | 0.48 |

LCP-HP35/W/P/H | 5.59 | 0.43 | - | - |

LCP55/A/P/R | 2.51 | 0.20 | - | - |

LCP55/A/S/R | 2.83 | 0.21 | - | - |

LCP55/W/P/C | 3.41 | 0 | - | - |

LCP55/W/P/R | 3.33 | 0.18 | - | - |

LCP-HP55/A/P/H | 3.2 | 0.37 | - | - |

LCP-HP55/W/P/H | 3.69 | 0.15 | - | - |

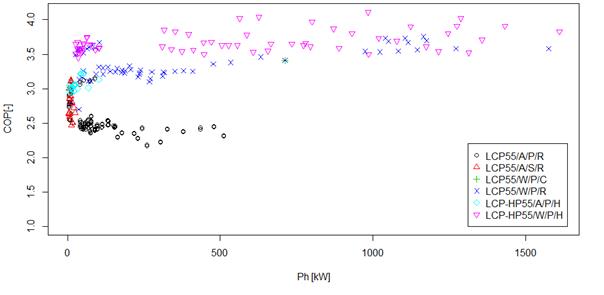

In high

temperature (55°C), as shown in Figure 8, the maximum average COP was

reached water based packaged LCP-HP units (LCP-HP55/W/P/H), 3.69 and the

minimum average 2.51 with air based packaged reversible units (LCP55/A/P/R). The

different types of LCP-HP units show to be clustered in different COP value

levels. This indicates that, particularly in high temperature heating mode, the

different types of units should be considered independently with regards to

minimum energy performance requirements.

Figure 7. COP values dispersion of the LCP-HP type low heating mode (35°C) units

according to its rated heating capacity (Ph). See Table 8 in Annexes for unit type.

Figure 8. COP values dispersion of LCP-HP unit in high heating mode (55°C) units

according to its rated heating capacity (Ph). See Table 8 in Annexes for unit type.

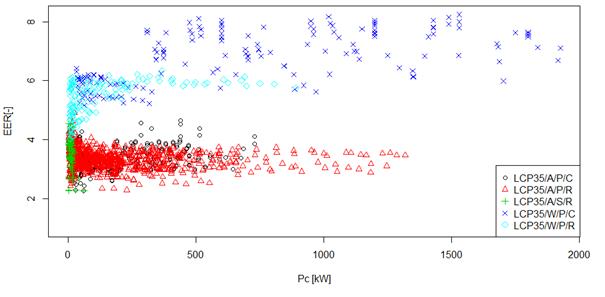

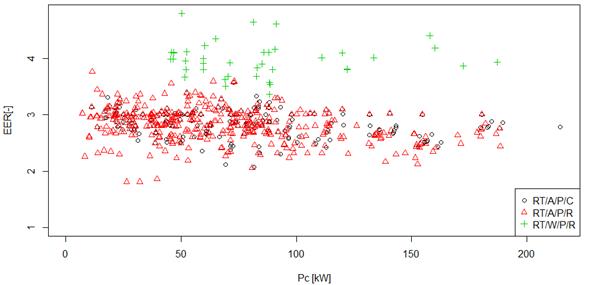

Figure 9 shows the EER values of LCP-HP units during the period 2014–2016. The maximum average EER among LCP-HP units in low temperature heating mode was 6.80 – in the case of water based packaged reversible units (LCP35/W/P/R), while the minimum was 3.38 in air based split reversible units (LCP-HP35/A/S/R). See Table 3.

Figure 9. EER values dispersion LCP-HP units according to its rated cooling

capacity (Pc). See Table 8 in Annexes for unit type.

LCP-HP

units are not yet considered under the energy labelling regulation. Thus, no

study on the seasonal energy efficiency (SCOP and SEER). However, the Eurovent

Certita Certification program [2], defines energy classes on the basis of the

COP and EER values [2]. Results of the market transformation between 2014 and

2016 can be found in the following couple of figures (Figure 10 and Figure 11). These results echo the stagnation

of the LCP-HP market. In the last three years, there are no signs of

significant positive evolution with respect to COP and EER values.

Figure 10. Coefficient of performance (COP) –transformation of LCP-HP between

2014 and 2016.

Figure 11. Energy Efficiency Ratio (EER) –transformation of LCP-HP between 2014

and 2016.

Figure 12 shows that RT present no clear

dependence between COP and unit rated capacity. In addition, the latter figure

reveals two clear clusters corresponding to water-based units with higher COP

values than air-based units.

Figure 12. COP values dispersion for each of the RT unit type in heating mode

according to its rated heating capacity. See Table 9 in Annexes for unit type.

Figure 13 shows that RT present no clear

dependence between COP and the rated capacity of the unit in cooling mode,

either. In addition, the latter figure reveals two clear clusters corresponding

to water-based units with higher EER values than air-based units, both cooling

only mode and reversible type.

Figure 13. EER values dispersion for each of the RT unit type in cooling mode

according to its rated cooling capacity (Pc). See Table 9 in Annexes for unit type.

Table 4 sums up average COP and EER values found for three different types of RT units (see types in Table 9). The water based packaged reversible systems (RT/W/P/R) present COP values 1.3 times higher than air heated units (RT/A/P/C and RT/A/P/R) in heating mode. The standard deviation values indicate a slight potential for positive effects to incite for energy performance improvement for heating applications.

The performance of water cooled RT units in cooling mode is also up to 1.4 times higher than air cooled packaged reversible units (RT/A/P/R). The standard deviation values indicate a slight potential for positive effects to incite for energy performance improvement in cooling mode.

Table 4. Summary of average and std. deviation COP and EER values for each RT

unit type.

COP Mean | COP Std. deviation | EER Mean | EER Std. deviation | |

RT/A/P/C | – | – | 2.87 | 0.23 |

RT/A/P/R | 3.24 | 0.28 | 2.80 | 0.28 |

RT/W/P/R | 4.31 | 0.19 | 3.94 | 0.30 |

As LCP-HP

units, RT are not considered under the energy labelling regulation. Thus, no

study on the seasonal energy efficiency (SCOP and SEER). However, the Eurovent

Certita Certification program [3], defines energy classes on the basis of the COP

and EER values. Results of the market transformation between 2014 and 2016 can

be found in the following couple of figures (Figure 14 and Figure 15) for air and water based RT

systems. These results echo the stagnation of the RT market. Except with

respect to water-based systems, in the last three years, there are signs of

positive evolution on EER values. From 2014 to 2016, 19% passed from lower

energy classes to class A.

|

|

Figure 14. Coefficient of performance (COP) –transformation of RT for air and

water based units between 2014 and 2016.

|

|

Figure 15. Energy Efficiency Ratio (EER) –transformation of RT for air and water

based units between 2014 and 2016.

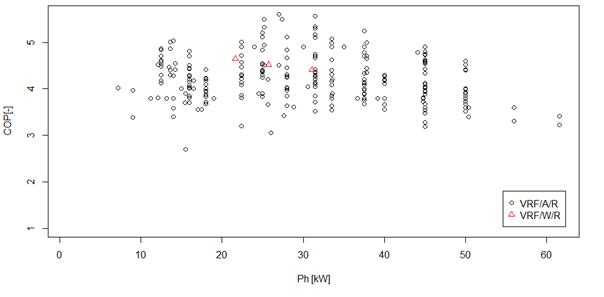

Figure 16 shows the COP values of VRF units

in heating mode sorted by unit type against its capacity. It is shown that water-

and air-sourced systems seem to have comparable performances. The evident

vertical lines corresponding to different heating capacities are defined by the

market.

Figure 16. COP values dispersion for each of the VRF unit type in heating mode

according to its rated heating capacity (Ph) See Table 10 in Annexes for unit type.

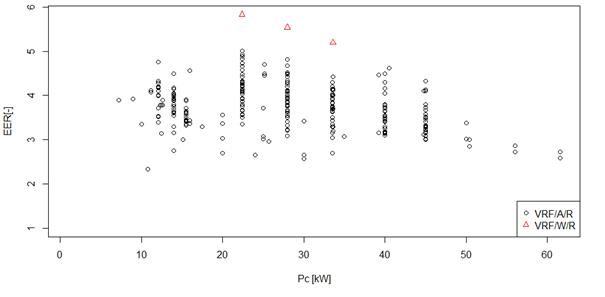

Figure 17 shows the EER values of VRF units

in cooling mode sorted by unit type against its capacity. Water-sourced units

present higher energy efficiency that air-sourced in cooling mode, contrasting

with what could be seen in heating mode, where these two types of units seem to

show comparable performances (Figure 16). This could be a result of

free-cooling. However, it is ambitious to conclude that this is a trend as

there are only three samples of water-sourced units available in this dataset.

Figure 17. EER values dispersion for each of the VRF unit type in heating mode

according to its rated heating capacity (Pc). See Table 10 in Annexes for unit type.

The maximum average COP among VRF units in heating mode was 4.53 –water based units (VRF/W/R), while the minimum was 4.22 in air based units (VRF/A/R). Table 5 summarizes the mean and standard deviation of COP and EER for each unit type in the last three years period (2014-2016).

Air based types present a larger standard deviation than water based. Yet, this might be due to the smaller numbers of water based samples. Thus, the potential for policy effect should be the same for air- and water- sources VRF units.

Table 5. Summary of average and std. deviation COP and EER values for each VRF

unit type.

Unit

Type | COP Mean | COP Std. | EER Mean | EER Std. |

VRF/A/R | 4.22 | 0.48 | 3.77 | 0.47 |

VRF/W/R | 4.53 | 0.10 | 5.52 | 0.28 |

VRF units

are not considered under the energy labelling regulation or any certification

program. Thus, no study on the seasonal energy efficiency (SCOP and SEER) or

nominal conditions efficiency (COP and EER) were performed.

This study

is based on accurate data of the performance of heating and cooling

technologies tested in independent laboratories. The technologies considered in

this study are: air conditioners, liquid chilling packages and hydronic heat

pumps, rooftop and variable refrigerant flow units.

The statistical

analyses performed and its results give an outlook of the technological

progress in European heating and cooling market during the period of 2014 and

2016. The facts presented prove the positive effect of energy labelling

implementation on energy efficiency improvement and confirm the importance of

standardised/legit data for heating and cooling technologies. Furthermore, the

facts strongly recommend the revision of the ecodesign requirements on the

minimum energy efficiency in the future revision of the regulation in the

matter of AC units. A review of the regulation No 206/2012 supplementing the

Directive 2010/30/EU with regard to ecodesign requirements of AC products is

planned. The Commission shall review the regulation No 206/2012 no later than 5

years from the date of entry into force.

With

respect to the other technologies (liquid chilling packages and hydronic heat

pumps, rooftops and variable flow refrigerant) studied in this work and its

future application with regards to energy efficiency improvement, it is

suggested that these systems should be discriminated by water and air-based

units when defining minimum requirements. In addition, packaged and split

systems also present distinguished performances.

In this

study, the AC units are classified according to their capacity:

·

AC1:

Comfort Air Conditioners and Heat Pumps rated up to 12 kW;

·

AC2:

Comfort Air Conditioners rated from over 12 kW up to but not including 45 kW

cooling capacity.

Furthermore, they are also classified according to its heat source, system and mounting types. AC units reject heat from the room to water (water cooled unit) or air (air/air units) in cooling mode and, if reversible, they can also absorb heat from the water or air to the room in heating mode. Table 6condenses the AC units classification used in this study.

Table 6. Non-ducted air conditioners (AC) classification.

Programme | Code | Heat rejection | Code | System | Code | Operation | Code | Mounting | Code |

Comfort Air

Conditioners up to 12 kW | AC1 | Air cooled | A | Split | S | Cooling only | C | High wall | W |

Floor mounted | L | ||||||||

Multisplit | M | Cassette | C | ||||||

Comfort Air

Conditioners from 12 up to 45 kW | AC2 | Water cooled | W | Reverse cycle | R | Ceiling suspended | S | ||

Packaged | P | Built-in horizontal | B | ||||||

Built-in vertical | V | ||||||||

Window | Wi |

Table 7 Energy Classification for Air

Conditioners except double ducts and single ducts.

Energy Efficiency Class | SEER | SCOP |

A+++ | SEER ≥ 8.50 | SCOP ≥ 5.10 |

A++ | 6.10 ≤ SEER ≤ 8.50 | 4.60 ≤ SCOP ≤ 5.10 |

A+ | 5.60 ≤ SEER ≤ 6.10 | 4.00 ≤ SCOP ≤ 4.60 |

A | 5.10 ≤ SEER ≤ 5.60 | 3.40 ≤ SCOP ≤ 4.00 |

B | 4.60 ≤ SEER ≤ 5.10 | 3.10 ≤ SCOP ≤ 3.40 |

C | 4.10 ≤ SEER ≤ 4.60 | 2.80 ≤ SCOP ≤ 3.10 |

D | 3.60 ≤ SEER ≤ 4.10 | 2.50 ≤ SCOP ≤ 2.80 |

E | 3.10 ≤ SEER ≤ 3.60 | 2.20 ≤ SCOP ≤ 2.50 |

F | 2.60 ≤ SEER ≤ 3.10 | 1.90 ≤ SCOP ≤ 2.20 |

G | SEER < 2.60 | SCOP < 1.90 |

The table below sums all the classes of LCP-HP units studied as classified by ECC [2].

Table 8. Classes of LCP-HP units.

Programme | Code | Heat rejection | Code | System | Code | Operation | Code | Duct | Code | Compressor | Code |

Liquid Chilling Packages | LCP | Air cooled | A | Packaged | P | Cooling only | C | Ducted | D | Centrifucal | C |

Water cooled | W | Split | S | Reverse cycle | R | Non Ducted | N | Other | O |

The table

below sums all the classes of RT units studied as classified by ECC [3].

Table 9. Classes of RT units.

Programme | Code | Heat rejection | Code | System | Code | Operation | Code |

Rooftop | RT | Air | A | Packaged | P | Cooling only | C |

Water | W | Reversible cycle | R |

The

following table below sums all the classes of VRF units studied as classified

by ECC [4].

Table 10. Classes of VRF units.

Programme | Code | Heat rejection | Code | Operation | Code |

Variable Refrigerant Flow | VRF | Air | A | Cooling only | C |

Water | W | Reversible cycle | R |

[1] ECC, Eurovent Certita Certification. RS 6/C/011-2016. [Online] [Cited: 07 10 2017.] http://www.eurovent-certification.com/en/Certification_Programmes/Programme_Descriptions.php?lg=en&rub=03&srub=01&select_prog=AC.

[2] ECC, Eurovent Certitita

Certification. RS

6/C/003-2017. [Online] [Cited: 07 10 2017.] http://www.eurovent-certification.com/en/Certification_Programmes/Programme_Descriptions.php?lg=en&rub=03&srub=01&select_prog=LCP-HP.

[3] ECC, Eurovent Certita

Certification. RS

6/C/007-2017. [En ligne] [Citation:

10 08 2017.] http://www.eurovent-certification.com/en/Certification_Programmes/Programme_Descriptions.php?n&rub=03&srub=01&select_prog=RT.

[4] RS 6/C/008-2016. [En ligne] [Citation: 10 08 2017.] http://www.eurovent-certification.com/en/Certification_Programmes/Programme_Descriptions.php?n&rub=03&srub=01&select_prog=VRF.

[5] Commission Delegated Regulation (EU) No 626/2011 of 4 May 2011. Commission, European. 2011. http://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX:32011R0626.

[6] Commission Regulation (EU) No 206/2012. Commission,

European. 2012. http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32012R0206.

[7] Energy Labelling Directive 2010/30/EU. Commission,

European. 2010. http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32010L0030.

[8] Regulation (EU) 2017/1369. Commission,

European. 2017. http://eur-lex.europa.eu/eli/reg/2017/1369/oj.

[9] ECC, Eurovent Certitita Certification. [En ligne] [Citation: 07 08 2017.] http://www.eurovent-certification.com/en/Certification_Programmes/Programme_Descriptions.php?lg=en&rub=03&srub=01&select_prog=LCP-HP.

[10] ECC, Eurovent Certita Certification. [En ligne] [Citation: 07 08 2017.] http://www.eurovent-certification.com/en/Certification_Programmes/Programme_Descriptions.php?n&rub=03&srub=01&select_prog=RT.

[11] [En ligne] [Citation: 07 08 2017.] http://www.eurovent-certification.com/en/Certification_Programmes/Programme_Descriptions.php?n&rub=03&srub=01&select_prog=VRF.

Follow us on social media accounts to stay up to date with REHVA actualities

0