Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

|

Heinrich Huber | Thomas Richter | Florian Brzezinski | Michael Riediker |

Institute of Building Technology and Energy, Lucerne University of Applied Sciences and Arts, Horw, Switzerlandheinrich.huber@hslu.ch | Hoval Aktiengesellschaft, Vaduz, Lichtenstein | Institute of Building Technology and Energy, Lucerne University of Applied Sciences and Arts, Horw, Switzerland | SCOEH: Swiss Centre for Occupational and Environmental Health, Winterthur, Switzerland |

Aerosols are considered a main cause of COVID-19 infections indoors. Therefore, limiting air transfer between supply and extract air in ventilation systems is critical.

In bidirectional ventilations systems, heat recovery is state of the art and is even required in the European regulation for ecodesign requirements for ventilation units. Rotary heat exchangers (RHE) are an efficient and economically interesting solution and are therefore widely used. A disadvantage of RHE is that due to the physical principle and the mechanical implementation a higher exhaust air transfer ratio (EATR) can occur than with other common heat recovery categories such as plate heat exchangers or run around coil systems. Measures to minimise and evaluate the EATR of RHEs are well known and recommended e.g. in the REHVA COVID-19 Guide [1]. Special attention must be paid to the correct pressure ratios and purge sector. However, RHEs are not generally equipped with purge sectors. Another aspect is the fact that the surface of an RHE is touched by both supply and extract air. Although this enables humidity recovery, it also carries the risk of transferring undesirable substances.

The characteristics of RHEs raise the question of whether relevant aerosol transfer can take place and whether this differs from EATR. For hygienically demanding applications of RHEs, it is crucial to have more knowledge about the phenomenon of aerosol transfer. On the initiative of a company, the University of Applied Sciences and Arts Lucerne (HSLU) together with the Swiss Centre for Occupational and Environmental Health (SCOEH) carried out experimental investigations [2].

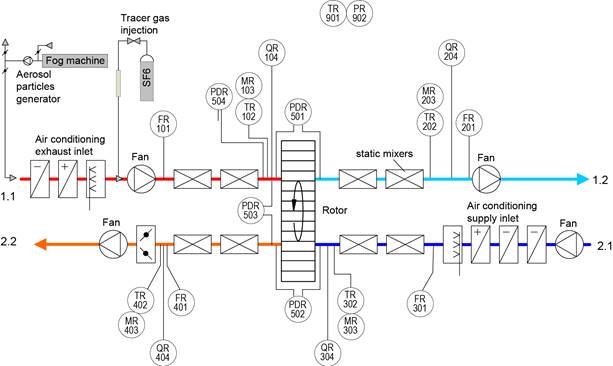

The Building Technology Laboratory of the HSLU operates a test rig for heat recovery devices. In Figure 1 the scheme of the test rig is shown. In all four air streams temperature, humidity, air flow rate and tracer gas concentration can be measured. For the aerosol measurements, a particle generator was installed in the exhaust air inlet duct and additional measuring devices in all four air streams.

Test objects were two RHEs without purge sector and with a free diameter of 1 000 mm: a condensation rotor (aluminium) and a sorption rotor (aluminium with molecular sieve coating). The nominal airflow is between 1 400 to 4 199 m³/h for a face velocity of 1 – 3 m/s. On both sides air inlet temperatures were 20°C ± 1K and air inlet humidity 40% RH ± 10% RH.

In order to make a conclusion of the aerosol transmission, the EATR and the aerosol transfer ratio (ASTR) were determined and compared.

Figure 1. Scheme of the test rig for heat recovery devices. Symbols: first letter F air flow rate, P pressure, T temperature, M humidity, Q concentration; subsequent letter D difference; auxiliary letter R registration; air flow type 1.1 exhaust inlet, 1.2 exhaust outlet; 2.1 supply inlet, 2.2 supply outlet.

The EATR was measured based on EN 308:2022 [3] by injecting Sulphur Hexafluoride (SF6) tracer gas in the duct of the exhaust inlet. The EATR is calculated with the following formula:

| (1) |

where

a11 is SF6 concentration exhaust inlet [ppm],

a21 is SF6 concentration supply inlet [ppm],

a22 is SF6 concentration supply outlet [ppm].

The test setup for the ASTR measurements was done in the same way as for the EATR. Aerosol measuring devices (Sensirion SPS30) were installed in pairs in each of the four air streams. The sensors count the particulate matter based on laser scattering in a size of 0.3 to 10 μm and provide a good assessment of concentrations over a wide range [4]. To keep the aerosol concentration in the supply inlet air as low as possible, the installed filters of the class ISO ePM1 50% (F7) were replaced with HEPA filters H14. During the measurement, aerosol was applied in pulses in the duct of the exhaust inlet air. The aerosol used has an average diameter of just over one micrometer and is therefore comparable in size to exhaled aerosol [5]. Like human exhaled aerosol, the used aerosol is liquid at normal ambient temperatures, hygroscopic and moderately viscous. It is produced by evaporation and condensation of a water-glycol mixture by a fog machine and is stable in air for a longer time [6].

The maximum peak heights at exhaust air inlet, supply air inlet and outlet were used for evaluation the ASTR according following formula:

| (2) |

where

b11 is peak PM10 exhaust inlet [P/cm³],

b21 is peak PM10 supply inlet [P/cm³],

b22 ispeak PM10 supply outlet [P/cm³].

For both EATR and ASTR, the measurement uncertainty was determined by repeating each test point usually five times. Since linearity is given for both measurement equipment, the measurement uncertainty can be determined by the standard deviation of EATR and ASTR and a coverage factor to reach a confidence level of 95%.

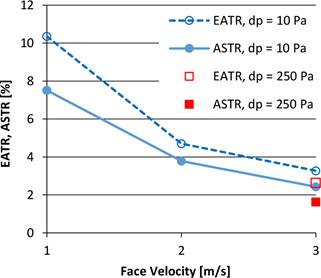

Table 1 shows the results of the condensation RHE. The measurements were conducted with three different air face velocities (v) of 1, 2 and 3 m/s. Rotor speed (n) was 20 rpm and pressure difference between supply outlet and exhaust inlet (Δp22-11) 10 Pa. One additional measuring point (MP) with a difference of 250 Pa between supply outlet and exhaust inlet was conducted.

Table 1. EATR and ASTR, condensation wheel.

MP, - | v, m/s | n, rpm | Δp22-11, Pa | EATR, % | ASTR, % |

1.1 | 1 | 20 | 10 | 10.4 ± 0.3 | 7.5 ± 3.7 |

1.2 | 2 | 20 | 10 | 4.7 ± 0.2 | 3.8 ± 2.3 |

1.3 | 3 | 20 | 10 | 3.3 ± 0.2 | 2.4 ± 0.6 |

1.4 | 3 | 20 | 250 | 2.6 ± 0.2 | 1.6 ± 0.2 |

Figure 2 shows the EATR and ASTR as function of the face velocity. Even if the ASTR plus the upper measurement uncertainty range partly exceeds the EATR, there is a clear tendency for the ASTR to be smaller than the EATR.

Figure 2. EATR and ASTR of the condensation rotor as function of the face velocity at isothermal conditions 20°C, 40% RH.

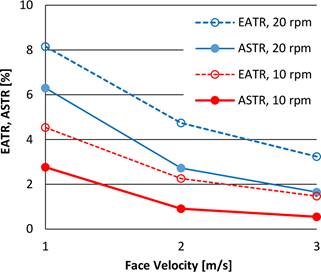

As with the condensation RHE, measurements with the sorption RHE were carried out at three different face velocities and a pressure difference of 10 Pa. Additional to the measurements with 20 rpm, measurements with 10 rpm rotor speed were conducted. Table 2 shows the results of the sorption RHE.

Table 2. EATR and ASTR, sorption wheel.

MP, - | v, m/s | n, rpm | Δp22-11, Pa | EATR,% | ASTR,% |

2.1 | 1 | 20 | 10 | 8.2 ± 0.3 | 6.3 ± 2.9 |

2.2 | 2 | 20 | 10 | 4.7 ± 0.2 | 2.7 ± 0.5 |

2.3 | 3 | 20 | 10 | 3.2 ± 0.2 | 1.7 ± 0.3 |

2.4 | 1 | 10 | 10 | 4.5 ± 0.1 | 2.8 ± 0.8 |

2.5 | 2 | 10 | 10 | 2.3 ± 0.2 | 0.9 ± 0.2 |

2.6 | 3 | 10 | 10 | 1.5 ± 0.2 | 0.6 ± 0.2 |

Analogous to the results of the condensation RHE Figure 3 shows that also with the sorption RHE the ASTR is below the EATR.

Figure 3. EATR and ASTR of the sorption rotor as function of the face velocity at isothermal conditions 20°C, 40% RH.

AHUs that comply with the European Ecodesign Regulation are typically designed for a face velocity (related to the inner cross-sectional area of the casing) of about 1.6 to 1.8 m/s. Since the face area of the of the RHE is about 10 to 20% smaller than the cross-sectional area of the AHU, the nominal face velocity of a RHE is typical approx. 2 m/s. In applications such as office buildings and schools, face velocities in the range of about 1 m/s often occur in partial load operation mode. On the other hand, the REHVA COVID-19 guideline recommends not using partial load operation in pandemic situations. Therefore, the measured EATR and ASTR at 2 m/s are considered for the infection risk assessment.

For condensation RHEs the rotor speed is in a range of 10 to 20 rpm, depending on design characteristics, e.g. foil thickness. For sorption RHEs 20 rpm can be seen as typical speed. Therefore, for the contamination risk assessment for both RHE types the measured values at 20 rpm are chosen. For the calculation of the contamination risk an ASTR of 4% is used, which is to understand as conservative value.

It goes without saying that these data are valid only for the tested RHE when using this specific fog aerosol. Nevertheless, the RHEs examined are real products that are judged to be typical in a market comparison.

The draft revision of the European Ecodesign Regulation from [7] serves as a comparison. In this draft a maximum EATR at nominal flow and nominal pressure of 5% is required. With reference to this source, a maximum EATR of 5% can be considered state of the art.

However, for hygienically sensitive applications, such as public buildings, the authors recommend taking measures to achieve a lower EATR. For RHE with a purge sector, an EATR below 0.5% can be achieved.

In German speaking countries the VDI 6022-1 [8] is considered reflecting the state of the art. The minimum filter class for supply air is ISO ePM1 50%. The extract air before entering a RHE shall pass a filter of class ISO ePM10 50%. As an estimate for the separation efficiency of lung aerosols the gravimetric arrestance of the filters up to a particle size of PM10 can be assumed to be 85% for class ISO ePM1 50% [9] and 50% for class ISO ePM10 50% (according to the definition of the class).

A typical solution is that in the outdoor air (before entering the RHE) and in the extract air (before entering the RHE) an ISO ePM1 50% filter is placed. Thus, the potentially contaminated air passes through only one filter.

The aerosol transfer ratio of an AHU ASTRAHU can be estimated as follow:

| (3) |

where

ASTRRHE is the ASTR of the RHE, acc. to Equation (2),

fF,eta is the separation efficiency of lung aerosols of an extract air filter (positioned before RHE),

fF,sup is the separation efficiency of lung aerosols of a supply air filter (positioned after RHE).

With the values shown in chapters 4.1 and 4.2, an ISO ePM1 50% filter in extract air and no additional filter in supply air, the result is an APTRAHU of approx. 0.006 or 0.6% respectively. This applies to RHEs without purge sectors. With purge sector, values 10 times lower can be achieved.

The amount of virus released into the air can be done by combining the concentration of viruses in the lung lining liquid with the size-distribution of micro-droplets released during breathing and speaking and by taking into account the proportion that sediments rapidly [10]. To estimate the viral concentration at steady state in different situations, we used an indoor scenario simulator that is based on this emission concept [11]. In all the calculated scenarios, we assumed that a very contagious person (a so-called super-emitter) is in a room of 100 m³ volume and 3 air changes per hour. We then simulated a quiet office, a loud office (e.g. call centre) and a hospital situation with coughing COVID-19 patients. We further assumed that 1000 people are in this building with a ventilation flow rate of 30 000 m³/h. For the general population, a very high infection rate of 1% is assumed, for the hospital wing with COVID-19 patients a rate of 50% (50% patients, 50% staff). Table 3 summaries the simulated virus concentrations in these scenarios in the individual rooms and in the extract air of the building.

The concentrations indicate viral copies as assessed by RNA assays. For the Delta variant about 1 in 300 and for the Omicron variant about 1 in 100 of these copies was found to be able to infect cells [12]. Thus, doses above 300 or even only 100 virus-copies seems to be critical for viral infections. This is supported by simulation of super-spreading events where the virus dose (the amount taken up) was estimated in the range of a few thousand viruses.

Table 3. Simulated virus concentrations (copies/m³) in individual rooms and in the extract air in different scenarios.

Scenario | Infection rate, | Steady state in room, | Extract air, |

Quiet office | 1 | 1200 | 1.2 |

Call centre | 1 | 40 000 | 40 |

Hospital, COVID section | 50 | 500 000 | 250 000 |

For the example of the call centre, it can be said that with an ASTRAHU of 0.6% and the virus concentrations in the extract air according to Table 3, the virus concentration in the supply air is 0.2 copies/m³. Even if the personnel directly inhale the supply air during an 8-hour shift (breathing air volume 0.6 m³/h), the amount of inhaled viruses is two orders of magnitude below the critical value for an infection risk. However, in a hospital situation with many highly emitting patients, the situation could rapidly become critical. Thus, the recommendation to use heat recovery systems without any risk of exhaust air transfer to supply air (e.g. tight plate heat exchanges or run around coil systems) in such settings is well warranted.

Eurovent 6/15 - 2021 [13] deals comprehensively and in detail with the prevention of air leakage in air handling units. According to this, an elementary measure is to ensure correct pressure conditions in air handling units. This depends primarily on the fan positions. For hygienically sensitive applications, a purge sector is also recommended.

It should be mentioned that the risk of exhaust air transfer also exists with other leakages in AHUs and ventilation systems that are not the subject of this paper.

The project investigated how aerosols, which behave similarly to human lung aerosols, are transferred in rotary heat exchangers without a purge sector under isothermal conditions. In the measurements on a condensation rotor, the exhaust air transfer ratio of the aerosols was around 1 percentage point lower than the exhaust air transfer ratio (EATR) of tracer gas. For a sorption rotor it was 2 percentage points lower. The results suggest that there is no risk of the used aerosols being transferred through the matrix with these rotary heat exchangers.

In the follow-up project further measurements with different products were carried out. The test report [14] is freely available, but the results have not yet been prepared for publication in a journal. However, it can be said that for rotors without a purge sector, the ASTR was always below the EATR, even with different air conditions. With a purge sector, EATR and ASTR were measured at a low level of 0.0 to 0.5%. Taking into account the measurement uncertainty, the EATR and the ASTR with purge sector can be described as approximately the same.

The authors would like to thank the company Hoval for initiating the project, the technical exchange, and the financial support.

[1] Federation of European Heating, Ventilation and Air Conditioning Associations. RHEVA COVID-19 guidance document, version 4.1. Brussels. 2021-04-15.

[2] Prüfstelle Gebäudetechnik. Test Report No.: HP-202084 Measurements on two Rotary Heat Exchangers. University of Applied Sciences and Arts (HSLU), Horw. 2021-03-09.

[3] EN 308:2022 Heat exchangers - Test procedures for establishing performance of air to air heat recovery components. CEN, Brussels.

[4] Tryner, J. et al. Effects of aerosol type and simulated aging on performance of low-cost PM sensors. Journal of Aerosol Science, Dec 2020; 105654.

[5] Johnsona G.R. et al. Modality of human expired aerosol size distributions. Journal of Aerosol Science 2011; 42.

[6] Maximoff S.N., Salehi A.A., Rostami A. Modality of human expired aerosol size distributions. Molecular dynamics simulations of homogeneous nucleation of liquid phase in highly supersaturated propylene glycol vapors; 2021.

[7] Draft Working Document on Ecodesign Requirements for Ventilation Units (Review EU1253/2014). European Commission, Brussels; 2021-03-01.

[8] VDI 6022 Blatt 1:2018-01 Ventilation and indoor-air quality - Hygiene requirements for ventilation and air-conditioning systems and units (VDI Ventilation Code of Practice). Verein Deutscher Ingenieure, Düsseldorf.

[9] Brunner A. Filterrichtlinie SWKI VA101-01 und VDI 3803/4. 6. Schweizer Hygienetagung, 2021-09-10.

[10] Riediker, M., Tsai, D.-H.. Estimation of Viral Aerosol Emissions From Simulated Individuals With Asymptomatic to Moderate Coronavirus Disease 2019. JAMA Netw Open 2020; 3, e2013807.

[11] Riediker, M., Monn, C.. Simulation of SARS-CoV-2 Aerosol Emissions in the Infected Population and Resulting Airborne Exposures in Different Indoor Scenarios. Aerosol Air Qual. Res. 2021; 21, 200531.

[12] Riediker, M. et al. Higher viral load and infectivity increase risk of aerosol transmission for Delta and Omicron variants of SARS-CoV-2. Swiss Med Wkly. 2022;152:w30133.

[13] Eurovent 6/15 – 2021 Air Leakages in Air Handling Units: Guidelines for Improving Indoor Air Quality and Correcting Performance. First edition. Eurovent European Industry Association, Brussels.

[14] Huber, H., Brzezinski, F., Riediker, M. Measurements of Aerosol Transfer by Rotary Heat Exchangers. TGA Report Nr. 8. Fachverband Gebäude-Klima e.V. (FGK), Ludwigsburg. 2022-03.

Full article: https://proceedings.open.tudelft.nl/clima2022/article/view/391

Follow us on social media accounts to stay up to date with REHVA actualities

0