Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

Olivier Tissot |

Project Manager at European Copper Institute |

The study conducted by Sphera and led by Dr. Constantin Herrmann investigates how copper tubing affects the environmental impact of drinking water installations systems over its entire life cycle, and compares them with those of drinking water installation systems based on multilayer aluminium-cross-linked plastic polyethylene (PEX-Al) and plastic cross-linked polyethylene (PEX) in Europe.

The study was critically reviewed by an external scientific panel of three independent reviewers (per the requirements of ISO 14040/44 and ISO/TS 14071, 2014). In accordance with the ISO requirements (ISO 14044, 2006), the overarching international standard for LCA, this document aims to report the results and conclusions of the LCA completely, accurately and without bias to the intended audience. The results are presented in a transparent manner and in sufficient detail to convey the complexities, limitations, and trade-offs inherent in the LCA. This allows the results to be interpreted and used in a manner consistent with the goals of the study.

The water installation systems considered are installed in houses and apartments as part of the larger plumbing and water distribution infrastructure. The function dispensed by the product system is the supply of hot and cold water within a dwelling to provide water supply at the point of use such as a washbasin or lavatory. The functional unit is defined as the ‘System supplying hot and cold water to an apartment of an area of 100 m2 and the installation is dimensioned according to EN 806. The installation design is identical for all three tube systems and the same conditions are taken into consideration, such as entry data, for all three systems (e.g., operating pressure). This unit, defined according to the function, allows for adequate comparability between the three different systems.

This assessment predominantly reports on the EN 15804 impact assessment indicators that are based on Environmental Footprint v3.0 impact assessment methods. According to EN 15804 (EN 15804+A2, 2019/2020) system boundaries are equivalent to a cradle-to-gate with options EPD including modules A1-A5, C1-C4 and module D. Modules B1-B7 are excluded. The reference service life (RSL) is identical for all investigated systems. The systems are supposed to serve the entire typical building lifetime of a minimum of 50 years (EN 15978, 2011/2012) and are typically also applicable for longer duration.

SYSTEM BOUNDARIES:

Included | Excluded |

ü Individual installation system supplying water within the apartment ü Raw material provision and manufacture of all components, types and parts the installation of a system’s needs (modules A1-A3) ü Transport to site and installation of the system into the apartment (modules A4-A5) ü End of Life (EoL) efforts as well as credits (modules C1-C4 and D) | û Common distributive installation supplying water to apartments û Use stage (modules B1-B7) û Overheads, infrastructure and other indirectly related aspects |

All background data are taken from the latest GaBi databases 2020 (Sphera Solutions GmbH, 2020a) and reflects the most recent and updated industry data on all relevant upstream (e.g., energy, intermediates, resources etc.) and downstream processes (e.g., waste treatment etc.).

The reported impact categories represent impact potentials and are approximations of environmental impacts that could occur if the emissions would follow the underlying impact pathway and meet certain conditions in the receiving environment while doing so. In addition, the inventory only captures that fraction of the total environmental load that corresponds to the chosen functional unit (relative approach). LCIA results are therefore relative expressions only and do not predict actual impacts, the exceeding of thresholds, safety margins or risks.

The EoL stage is of particular importance for copper tubing. It consists of five steps, modules C1-C4 and module D. The copper looped scrap is based on the sum of scrap from manufacturing of copper tubes and the EoL of the system. Recycling, such as the EoL recycling rate and recycling content (e.g., apart dissipative loss, copper is infinitely recyclable) for the assessed tubing systems are industry averages in accordance with state-of-the-art industrial practices and expert judgement. It represents a quantified illustration of an exemplary circular economy model.

The LCIA results of all three product systems have been calculated for ten impact categories (climate change as one aggregated value) according to EN 15804, only the most impactful regarding the green energy transition are shown as follows (see ANNEX for full results):

Impact Category | Description | Unit |

Climate change, Global Warming Potential (GWP) | A measure of greenhouse gas emissions, such as CO₂ and methane. These emissions cause an increase in the absorption of radiation emitted by the earth, increasing the natural greenhouse effect, and has adverse impacts on ecosystem health, human health and material welfare. | kg CO₂ equivalent (CO₂ eq.) |

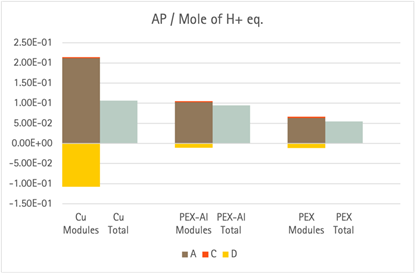

Acidification Potential (AP) | A measure of emissions that cause acidifying effects to the environment. The acidification potential is a measure of a molecule’s capacity to increase the hydrogen ion (H+) concentration in the presence of water, decreasing the pH value. Potential effects include fish mortality, forest decline and the deterioration of building materials. | moles H+ equivalent (H+ eq.) |

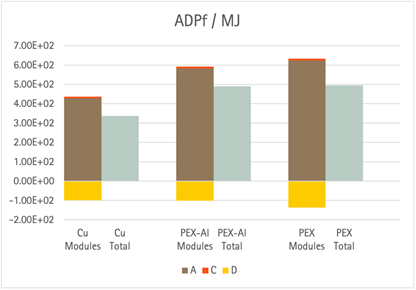

Resource use, fossil fuels and energy carriers, Abiotic Depletion Potential fossil (ADPf) | A measure of the total amount of non-renewable primary energy extracted from the earth. Resource use is expressed in energy demand from non-renewable resources including both fossil sources (e.g. petroleum, natural gas, etc.) and uranium for nuclear fuel. Efficiencies in energy conversion (e.g. power, heat, steam, etc.) are taken into account. | MJ (net calorific value) |

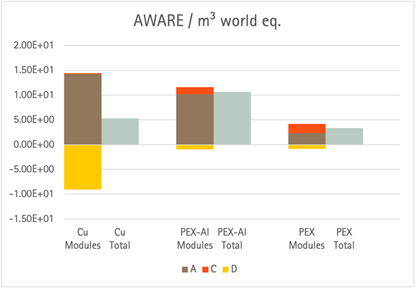

Water Use (AWARE) | An assessment of water scarcity accounting for the net intake and release of fresh water across the life of the product system considering the availability of water in different regions. The method is also called Available Water Remaining (AWARE). | m³ of water equivalent (m³ world eq.) |

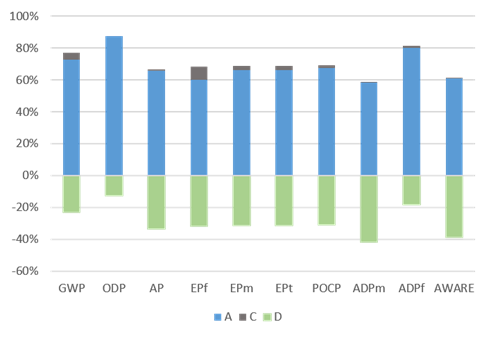

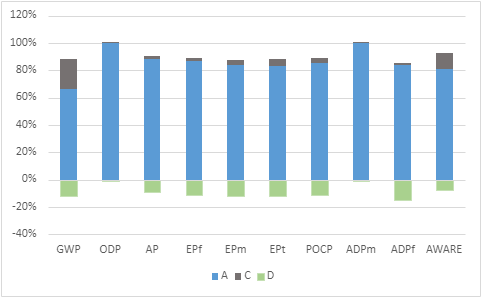

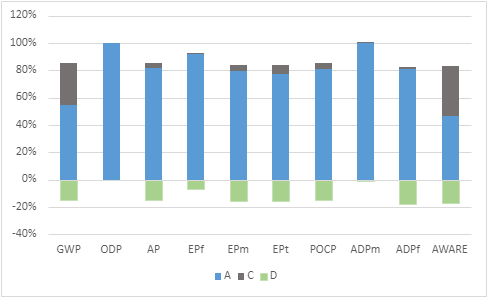

The following graphics show the contribution of the life cycle stages A, C and D, for the three systems:

Benefits from module D (green), the possibility of the substitution of copper cathode, lower the overall impacts of all impact categories. Landfilling and the incineration of waste without credits (worst case approach) in module C (grey) only shows positive impacts.

For the PEX-Al and the PEX system, waste incineration in module C (grey) and credits in module D (green) result in net negative impacts for eight out of the ten impact categories, of which ODP and ADPm are so low that they can be neglected. Only GWP and AWARE have higher C impacts than D credits.

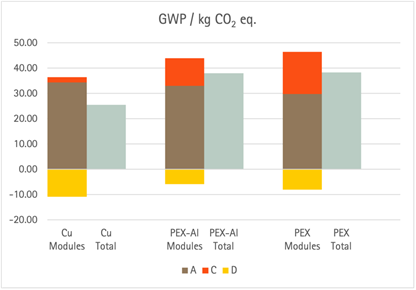

The comparison of the results of the three systems for each impact category shows the absolute values for modules A, C and D (left column for each system) as well as the net total (right column for each system). It is emphasized that the baseline for a comparison refers to the separately displayed modules excluding module D as it refers to future life cycles with credits from avoided primary material beyond the product system under consideration. However, the closed-loop market for copper is so much established that the module D credits belong to a state-of-the-art market situation. Therefore, the comparison can be seen twofold, one with modules A and C only and one including module D. For simplification, the net credit value is displayed and has to be understood as additional information.

The PEX and PEX-Al Systems show similar results for the sum of A and C (44 and 46 kg CO₂ eq.) while the Copper System is linked to lower GWP results of 36 kg CO₂ eq. The benefits outside the product system in module D provide a remarkable upside for the copper system compared to the PEX-Al system and the PEX system (Cu: -10.9, PEX-Al –5,92, 46% difference to Cu, PEX –8,10, 26% difference to Cu) This results in 25 kg CO₂ eq. for the copper system compared to the 38 kg CO₂ eq. of the two PEX systems.

Both PEX-based systems (Modules A+C) are related to significant lower acidification potential than the copper system. However, including benefits from module D, the copper system is reduced to compare almost equally to PEX-Al (some influence)

Both PEX-based systems are related to highest fossil abiotic depletion potential and are relevantly higher compared to the copper system for both situations, the modules A and C as well as at the net total.

From a net total perspective, PEX-Al has the highest potential impact in the AWARE category. This is based on the water consumption for manufacturing, which does face lower potential credits in module D compared to the impacts of C. This causes the net potential impacts of the PEX-Al system to be significantly higher than for the copper system, whereas the net impacts of the PEX system are still relevantly lower than those of the copper system.

Within the three systems of consideration, the materials and their fabrication dominate between 85 and 90 percent of the life cycle. The copper tubing system provides potential credits from recycling in module D in future product life cycles. The PEX systems instead are linked to benefits from energy recovery of the incineration. The balance between impacts from material incineration and credits from energy systems is also seen from the high dynamic European energy systems change due to energy transition towards low carbon energy—changes specifically for impact categories such as GWP, AP, ADPf and AWARE are then likely to occur.

The comparative LCA shows that the copper-based water tube installation system is equally in the level of environmental impact for module A+C compared to PEX-Al and PEX (lead indicator GWP). In addition, the recyclability of copper provides potential credits in module D in future product life cycles, so that the net total values show a clear advantage (lower values) for copper compared to PEX-Al as well as PEX. This applies to ADPf in the same way, for which even module A+C is already lower. AP shows higher impacts from of the copper system for module A+C but are potentially reduced by module D down to a comparable level as the PEX based systems. For water consumption (AWARE) the module A+C of copper is higher than the PEX systems, but rank in between both (lower than PEX-Al, higher than PEX) using net total values.

Additionally, the copper system has even more reduction potentials from material savings and avoidance of primary material as the sensitivity and scenario analyses show.

Follow us on social media accounts to stay up to date with REHVA actualities

0