Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

This article is based on a paper presented at the 42nd AIVC - 10th TightVent & 8th Venticool Conference “Ventilation Challenges in a Changing World” held on 5-6 October 2022 in Rotterdam

|

|

Nolwenn Hurel | Valérie Leprince |

PLEIAQ2 Avenue de Mérande73 000 Chambéry, FranceCorresponding author: nolwenn.hurel@pleiaq.net | Cerema2 rue Antoine Charial69003 Lyon, France |

In a context of energy use reduction, low energy buildings are becoming more widespread. This kind of construction require a good envelop airtightness to prevent uncontrolled leakages of conditioned air leading to energy losses. As a result, more and more ventilation systems are installed to ensure a sufficient air change rate for a good indoor air quality.

However, in practice many issues are found with the installed ventilation systems not providing the expected flowrates. In France a study on 1287 dwellings showed that 68% do not meet the regulation (Jobert and Guyot, 2013). More and more countries have a mandatory inspection of ventilation systems, such as Sweden, Ireland, Germany and France.

This article aims at comparing the various approaches to help provide guidelines on the inspection of ventilation systems. It is based on an EPBD feasibility study detailing 20 protocols from 9 countries (Durier et al., 2019) with the addition of the new guide to comply with Irish regulations and a survey addressed to various countries for technical details. This article is based on a paper presented at the 42nd AIVC - 10th TightVent & 8th Venticool Conference “Ventilation Challenges in a Changing World” held on 5-6 October 2022 in Rotterdam, Netherlands (Hurel and Leprince, 2022), including in particular the list of the 21 protocols from 10 countries summarized below.

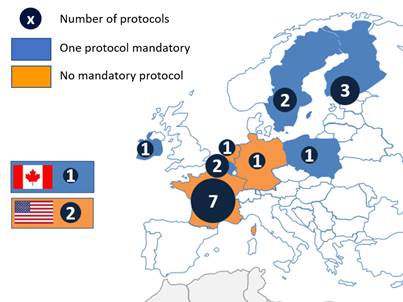

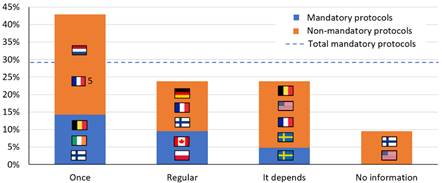

Only six countries have a mandatory protocol (by legislation or regulation): Poland, Belgium (in Flanders only), Finland, Ireland, Sweden and Canada. The other 15 protocols are mostly non-mandatory guidelines (13) and two standards from France and the USA.

Some countries have several protocols, with a maximum of 7 in France, as illustrated in Figure 1.

Figure 1

Half of the mandatory protocols (3) and almost half of the non-mandatory ones (7) are dedicated to residential buildings only, while the other half is for both residential and non-residential buildings. There is only one protocol, in the USA, that does not include residential buildings and is dedicated to commercial and institutional buildings only. In this country, the other protocol applies to apartments only when each of them has its own/independent ventilation system.

The Canadian protocol is aimed for health care buildings only, that is to say hospitals, laboratories, psychiatric and mental health service facilities, long-term care homes and residences for persons with developmental or physical disabilities.

In Netherlands, the non-commercial buildings covered by the one protocol are only the educational ones (Figure 2).

|

|

Figure 2 | |

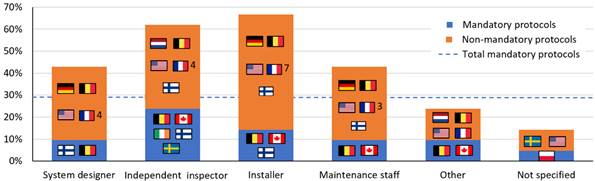

Among the mandatory protocols, there is only in Poland that has no specification about who can operate the inspection. All other mandatory protocols allow or require (in Ireland and Sweden) an independent inspector.

Non-mandatory protocols are overall more flexible on who is performing the inspection, with in particular most of them (11 out of 15) allowing the installer to control (Figure 3).

Figure 3

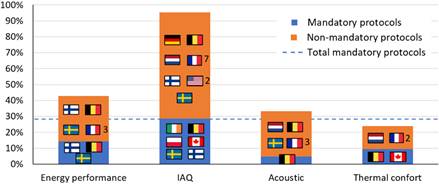

All protocols cover the indoor air quality (IAQ) aspect, except one in Finland; less than half of them cover the energy performance and/or the acoustic performance, and a quarter only cover the thermal comfort aspect (Figure 4).

Figure 4

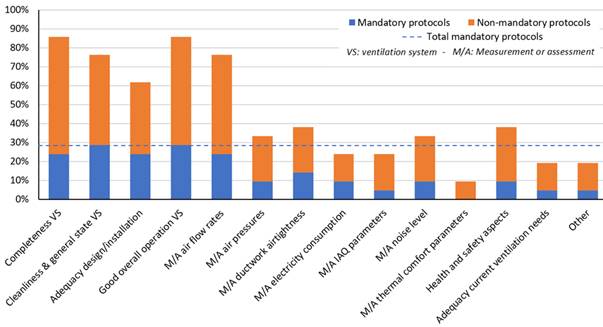

Most protocols cover a wide range of aspects as illustrated below. For example, all mandatory protocols cover the control of cleanliness, general state and good overall operation of the ventilation system (VS), and more than half of all protocols cover also the completeness of the VS, the adequacy between design and installation and a measurement or assessment of the air flow rates (Figure 5).

Figure 5

About half of the protocols (mandatory or not) are intended for a single inspection.

For the other half, concerning mandatory protocols:

· in Poland it is required to have an inspection at least every 5 years,

· in the Ontario State since the protocol is for health care facilities a periodicity of 6 months is required,

· in Sweden it depends on the type of buildings:

o every 3 years for day-care centres, schools etc. with all types of ventilation; blocks of flats, office buildings etc. with balanced ventilation

o every 6 years for blocks of flats, office buildings etc. with mechanical exhaust and natural ventilation;

o single inspection for one and two-dwellings houses with mechanical exhaust with exchanger ventilation and balanced ventilation.

In Belgium, for the non-mandatory protocol the guide proposes different inspection frequencies from 1 month to 3 year-intervals depending on the type of components: 1 month for filters, 3 months for the natural openings, air intakes, exhaust devices, 1 year for heat exchangers and fans, 3 years for ducts (Figure 6).

Figure 6

A survey of 21 technical questions was sent to get to know better how specific technical issues are handled for the inspection of ventilation systems according to the various protocols.

5 answers were collected from 5 countries: Belgium, Ireland and Sweden for their mandatory protocols, France for the non-mandatory protocol “Promevent” and USA for the non-mandatory protocol for residential buildings. Only a few of the 21 questions are addressed in this article, but they are all detailed in (Hurel and Leprince, 2022).

Note: In the illustrations of this survey, the flags have black edges for the countries with mandatory protocols and white edges for non-mandatory protocols.

Interior doors: |

|

| |

Ventilation openings: |

|

| |

Concerning the preparation of the building before the measurements, the respondent from Sweden did not specify about the opening of interior doors and sealing of ventilation openings in his answer. For the other protocols, the interior doors must be closed for all but the US one and all trickle-vents must stay open (in France they cannot be closable). Other specifications are required depending on the protocols (Hurel and Leprince, 2022).

![]()

In the USA the constraint is 10 second averaging (except for bag filling). In France the flowrate measurement must last at least 10 seconds. In Belgium the minimum duration of the total measurement of the building is 20 minutes but there is no constraint on an individual ATD.

![]()

The flowrate measurement inside the ductwork is an option for all protocols but the Irish one. In the USA, there are limitations on distances to upstream and downstream fittings as specified by the instrument manufacturer. In Belgium specific conditions for the ductwork measurement should be respected: e.g. minimum straight length of the duct before and after. In practice it is only performed if measurement of ATD is not possible. In Sweden, according to the regulations, flows must be measured in all branches of the systems.

In the USA, the protocol does not address this issue directly, but it allows several alternative approaches including in-duct measurement. In Belgium they use ductwork measurement, or other solution from set of allowed solutions for measurement. Otherwise, they report “not measurable” (= 0 m³/h). In Ireland the issue is noted in report, not dealt with specifically. In Sweden measurements are then made in the duct or with a “hook” in the device. In France, airflow measurement is not possible in this case: measurement is not valid. If a pressure measurement can be done instead, this can be a solution: then one should make sure that the measuring device is adapted to the type of ATD.

![]()

There are requirements on measuring devices according to the kind of ATD for exhaust systems for all protocols but the Swedish one. In the USA, for an inlet terminal the airflow is permitted to be measured using a Powered Flow Hood, using an Airflow Resistance Device or using a Passive Flow Hood. In Belgium it is advised to always use stabilisation grid and largest hood, but the measurement is accepted without if the situation makes it not possible. In France, for humidity sensitive ATD, only pressure measuring devices must be used whereas for the other kinds of ATD, either pressure or airflow measuring devices can be used.

A calibration period is defined in each protocol. In the USA, all equipment shall have their calibrations checked at the manufacturer’s recommended interval and at least annually if no time is specified. In Belgium it is 2 years; for flow devices and 5 years for power meters; in Ireland and Sweden it is one year and in France it is 2 years for manometers and maximum 4 years for flow hoods.

![]()

In Sweden every non-conformity should be corrected. In Ireland also, but it depends on flow rates. In the USA, the protocol is a method of test not a regulation and does not cover the consequences of not meeting target flows. In Belgium a table of non-conformities with sanction is available. Some should be corrected, some not. In France all of the non-conformities should be mentioned in the report or in the grid of inspection, differentiating those that relate to regulation or good practices.

![]()

There are two distinct approaches to consider a dwelling to be conform in terms of air flow rates. On one hand, in France and in Ireland it is the total flowrate that is required to be conform. On the other hand, for the other protocols (Sweden, USA and Belgium) every ATD shall be conform. In Sweden requirements for air flows are calculated by a consultant on information from the user and regulatory requirements.

![]()

The Belgium and Swedish protocols are the only two covering also non-residential buildings and require that every room shall be conform.

The authors would like to thank the respondents to the survey: Iain Walker (LBNL) in the USA, Maarten De Strycker (BCCA) in Belgium, Simon Jones (Aereco Ltd) in Ireland, Olof Nevenius (Funktionskontroll-anterna i Sverige) in Sweden and Ariane Lesage (Cerema) in France.

This work was supported by BCCA and INIVE.

Department of Housing, Planning and Local Government, 2019. Installation and Commissioning of Ventilation Systems for Dwellings - Achieving Compliance with Part F 2019.

Durier, F., Wouters, P., De Strycker, M., Guyot, G., Sherman, M.H., Leprince, V., Urbani, M., 2019. Feasibility Study EPBD Art. 19a - Existing regulations, standards and guidelines on the inspection of ventilation systems, and other relevant initiatives and projects (No. ENER/C3/2018-447/05). Client: European Commission’s Directorate General for Energy.

Hurel, N., Leprince, V., 2022. Inspection of ventilation systems – summary of existing protocols and technical survey. Presented at the 42nd AIVC-10th TightVent- 8th venticool conference, Rotterdam, The Netherlands.

Jobert, R., Guyot, G., 2013. Detailed analysis of regulatory compliance controls of 1287 dwellings ventilation systems, in: Proceedings of the 34th AIVC - 3rd TightVent - 2nd Cool Roofs’ - 1st Venticool Conference. Athens, Greece.

Follow us on social media accounts to stay up to date with REHVA actualities

0