Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

Jiří Hemerka | Pavel Vybíral |

doc. Ing, CScDepartment of Environmental Engineering, Faculty of Mechanical Engineering, Czech Technical University in Praguejiri.hemerka@fs.cvut.cz | Ing., Ph.D.Department of Environmental Engineering, Faculty of Mechanical Engineering, Czech Technical University in Praguepavel.vybiral@fs.cvut.cz |

The correct use of atmospheric air filters for general ventilation is based on the separation ability of the filters, expressed as a function of the fractional efficiency on the particle size, on the particle size distribution and the concentration of the particles in the carrier air in a given case.

The ISO 16890-1 standard from December 2016 [1] brought, in comparison with EN 779 [2], new valuable direct information about the separation abilities of filters and after incorporation into the structure of EN in 2016 ([3], [4], [5], [6]), was expected to be widely used, especially in Europe. The concurrence of the EN 779 and EN ISO 16890 standards ended in the middle of 2018. Since then, there should have been only two systems in the world – ISO 16890 (EN ISO 16890) and the American ASHRAE 52.2.

The reality of the transition to the new standard during 2020 is somewhat different than from what was envisaged in the transition schedule. The revision and repeal of EN 13779:2007 [7] in the field of ventilation of non-residential buildings and the creation of the new EN 16789-3:2017 guideline (Energy performance of buildings - Ventilation of buildings – Part 3: For non-residential buildings) [8] also “contributed” to the delay. In this basic and widely used standard, in the field of ventilation of non-residential buildings, revised with effect from August 2017, the basic text in Table 17 shows the minimum filtration efficiency requirements in [%] for 15 combinations of internal and external pollution; however, in Annex B Default choices in Table B.3 of the recommended minimum filter classes for each combination of external pollution category (ODAi) and the required quality (category) of the supply air (SUPi), there is a recommendation to still use the filter classes according to EN 779, and not to the ePMₓ filter class according to EN ISO 16890 (Revision of the EN 16798-3:2017 is ongoing.).

As stated in contribution [9], to successfully transfer to a new classification system, the designers would need to answer the basic question: “For the specific application, the proven filter class has been used according to EN 779 so far. Which filter class is to be used according to the new standard?”

The answer is not simple, because due to the differences in the classification systems, there is no direct conversion between the two systems. In addition, there is a solution duplication, because, for example, some ePM2.5 base group filters with a higher efficiency can be replaced by the ePM1 base group filters with a lower efficiency.

With regard to the seriousness of the issue of the filter class conversion between EN 779 and EN ISO 16890-1, the following chapters briefly present the characteristics of the new filter classification, summarise the main differences between the two sorting systems and provide an overview of the available conversion relationships.

The aim of the paper is to contribute to overcoming the existing, and going beyond the expectations of a long and undesirable, transition period and to put the new sorting system into practice.

ISO 16890-1, from December 2016 [1], introduces new indicators for the testing and classification of filters – the particulate matter fractions PM10, PM2.5 and PM1.

The individual filter classes are defined according to the achieved ePMₓ efficiency for the stated atmospheric dust fractions, starting with a particle size of 0.3 µm.

This standard was included in the structure of the EN standards as early as December 2016 as [3], [4], [5], [6].

The particulate matter fractions PM10, PM2.5 and PM1 are defined in air pollution control as atmospheric dust particles smaller than the aerodynamic particle size of 10, 2.5 and 1.0 µm. The particle size of the atmospheric dust is expressed in the form of the so-called aerodynamic particle size, i.e., the diameter of a spherical particle with a unit density of a particle material of 1000 kg/m³, which has the same kinetic properties as a true non-spherical particle.

The ISO 16890 regulation itself works with the ePMₓ efficiency, which expresses the mass efficiency of the “device” separation (filter efficiency), determined for the particulate matter fractions in the range of the optically determined particle sizes of 0.3 to x µm - see Table 1. This regulation, thus, ignores the difference between the aerodynamic diameter of a particle and the optically determined particle size. The limitation of the ePMₓ value, only for particles x ≥ 0.3 µm, is given by the limitation of the resolution of conventional optical instruments for particles of size < 0.3 µm.

Table 1. Particle size range for the definition of the efficiencies.

Separation efficiency | Range of optically determined particle sizes [µm] |

ePM10 | 0.3 ≤ x ≤ 10 |

ePM2.5 | 0.3 ≤ x ≤ 2.5 |

ePM1 | 0.3 ≤ x ≤ 1 |

When testing the filter, its separation abilities should be measured in the range of the optically determined particle sizes of 0.3 to 10 µm in a KCl aerosol at twelve size intervals, first with a clean and electrically unconditioned filter according to the procedure given in ISO 16890-2. The individual values of the separation efficiency Ei [%] are obtained by measurement.

After neutralisation of the charge in the filter material according to ISO 16890-4 (discharge of the charge in the isopropyl alcohol (IPA) vapours), the separation abilities of the electrically neutral filter are again determined in twelve size intervals in the particle size range of 0.3 to 10 µm, the ED,i values [%]. The dependence of ED(a) is considered to be the minimum value of the fractional efficiency of the filter.

By loading the filter with fine synthetic dust, L2, according to ISO 15957 (base dust without soot and fibre admixtures) and following the procedure given in ISO 16890-3, the initial value of the filter gravimetric arrestance of the synthetic dust is determined, then the dependence of the change in the pressure loss of the filter on the weight of the collected dust and the value of the filter test dust capacity is determined.

From the individual determined values of Eiand ED,i, the mean arithmetic values of EA,i, are determined, which are further considered as the mean values according to which the filter will behave in real conditions.

The individual values of EA,i [%], with respect to the dependence EA(a) is further used in the calculation of the particulate matter efficiency ePMₓ of the filter in the range of the particle sizes of 0. 3 to x µm.

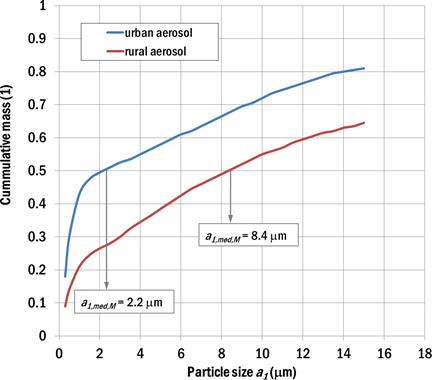

The average composition of atmospheric dust in urban areas and in rural areas is used to calculate the ePMₓ values [%]. The distribution of the particle sizes by mass (volume), in the form of the expression of the frequency (discrete) and the cumulative distribution curve, is shown in the contribution [10] in Figure 4. The bimodal frequency mass distribution is a characteristic feature of the particle size distribution of both typical atmospheric dusts. For a better comparison of the differences, the cumulative mass curves of the two atmospheric dusts used are expressed in linear particle size coordinates in Figure 1.

The mass fraction of the particles smaller than 0.3 µm (undersize cumulative mass) depends on the air pollution, which is not negligible and generally reaches values of the order of 30%. According to the data in Figure 1, the proportion of the particles smaller than 0.3 µm in these atmospheric dusts is 18 and 9%, respectively. From a common point of view, it follows that there are significant differences between the two atmospheric dusts. The most used characteristic feature of the particle granularity is the mass median amed,M, which reaches values of 8.4 and 2.2 µm for these dusts, respectively.

Figure 1. Average composition of the atmospheric dust in urban and rural areas.

According to the recommendations in ISO 16890, the filters, which are mostly used for the separation of PM1 and PM2.5 particulate matter fractions, are classified according to the particle size distribution of the atmospheric dust in urban areas and the filters primarily intended for the separation of the PM10 particulate matter fraction are classified according to the particle size of the dust in rural areas. The calculated values of ePM1 and ePM2.5 [%] are, therefore, based on the distribution curve for an urban aerosol, the value of ePM10 [%] is based on the distribution curve for a rural aerosol. We remind you that the calculated mean arithmetic values of the EA,i efficiencies [%] for the individual size fractions, are used to calculate the ePMₓ values [%].

In addition to these mean values, which are among the main reported filter parameters (class reported value), when processing the measurement results, the calculation is supplemented by determining the minimum values of ePM1, min and ePM2.5, min [%] according to the detected values of the minimum ED,i efficiencies [%] for the individual size fractions.

Based on the test results, the filters are classified according to the requirements for ePM1, min and ePM2.5, min [%] and for ePM10 [%] into the following 4 basic groups - ISO coarse, ISO ePM10, ISO ePM2.5 and ISO ePM1, see Table 2.

Table 2. Filter classification according to ISO 16890.

Basic group of filters | Filter group requirement | Class reporting value | ||

ePM1, min | ePM2.5, min | ePM10 | ||

ISO coarse | - | - | < 50% | Initial arrestance for synthetic dust |

ISO ePM10 | - | - | > 50% | ePM10 |

ISO ePM2.5 | - | > 50% | - | ePM2.5 |

ISO ePM1 | > 50% | - | - | ePM1 |

In addition to this basic classification, the value of ePMₓ [%] found for each filter tested, determined according to the mean values of the fractional efficiencies EA,i [%] (the value in the last column of Table 2) is presented. The ePMₓ value [%] is rounded down to a multiple of 5%.

For the basic ISO coarse class, the initial test value for synthetic dust, rounded down to a multiple of 5%, is given as the test result.

As follows from the interpretation of the requirements for the classification of the filters according to the values in Table 2 and as stated in the EUROVENT Guidebook [11] from 2017 and in the contribution [9] from 2018, the following filter quality options exist according to ISO EN (Table 3).

Table 3. Filter classification table according to ISO 16890.

ePM1 classification | ePM2.5 classification | ePM10 classification | ISO coarse |

ePM1 (95) | ePM2.5 (95) | ePM10 (95) | Gravimetric arrestance reported in full 5% |

ePM1 (90) | ePM2.5 (90) | ePM10 (90) | |

ePM1 (85) | ePM2.5 (85) | ePM10 (85) | |

ePM1 (80) | ePM2.5 (80) | ePM10 (80) | |

ePM1 (75) | ePM2.5 (75) | ePM10 (75) | |

ePM1 (70) | ePM2.5 (70) | ePM10 (70) | |

ePM1 (65) | ePM2.5 (65) | ePM10 (65) | |

ePM1 (60) | ePM2.5 (60) | ePM10 (60) | |

ePM1 (55) | ePM2.5 (55) | ePM10 (55) | |

ePM1 (50) | ePM2.5 (50) | ePM10 (50) | |

Requirements: > 50% initial efficiency > 50% discharged efficiency | Requirements: > 50% initial efficiency > 50% discharged efficiency | Requirements: > 50% initial efficiency No minimum discharge efficiency | No discharge requirements |

From Table 3, it follows that, theoretically, there are a total of 49 classes of filters in 4 different basic groups (classes), 10 classes each in PM1, PM2.5 and PM10 and 19 classes in the basic ISO coarse group.

As already mentioned in the introductory chapter, a direct conversion relationship between the filter classes according to EN ISO 16890 [3], [4], [5], [6] and EN 779 [2] does not exist and cannot exist, because both classification systems are too different. The existing conversion relationships serve only as a rough guide on how to use the existing experience with the use of filter classes according to EN 779 in the new system, which is only slowly being applied in practice. This chapter briefly summarises the basic characteristics and differences of both classification systems.

The classification, according to EN 779, is based on the class F and M filters on the mean filtration efficiency Em for 0.4 µm particles (DEHS aerosol particles with an optically determined particle size) during the dust loading test and on the coarse G filters on the average gravimetric efficiency (arrestance) of the Am filter on the loading test dust. This is, therefore, the efficiency of the medium-loaded filters. The loading dust contains admixtures of soot and cotton linters in addition to the fine desert dust. In the 2012 amendment, a requirement for determining the minimum filtration efficiency for 0.4 µm particles, for electrically discharged filter materials, was introduced for the F filter classification, which respects the observed significant change in the separation capabilities of some synthetic fibre filter materials.

The classification, according to EN ISO 16890, is based on the determination of the separation abilities of the clean electrically untreated and electrically neutral material in the range of optically determined KCl aerosol particle sizes of 0.3 to 10 µm. The range of the particle sizes is divided into twelve size intervals and, for each interval, the mean arithmetic value EA,i is determined, which is further considered as the mean value according in which the filter will behave in real conditions. The individual values of EA,i [%], respectively, the dependence EA(a) – are further used in the calculation of the filter efficiency value ePMₓ in the particle size range of 0.3 to x µm.

The average composition of the atmospheric dust in urban areas and in rural areas is used to calculate the ePMₓ values [%]. The calculated values of ePM1 and ePM2.5 [%] are based on the distribution curve for an urban aerosol, the value of ePM10 [%] is based on the distribution curve for a rural aerosol. In addition to these ePMₓ values [%], which are rounded down to a multiple of 5% and which are among the main reported filter parameters (class reported value), when processing the measurement results, the calculation is supplemented by setting the minimum values of ePM1, min and ePM2.5, min [%] according to the determined values of the minimum ED,i [%] efficiencies for the individual size fractions.

By loading the filter with the fine synthetic dust L2 according to ISO 15957 (base dust without admixtures of soot and linters), the initial value of the filter efficiency to the synthetic dust (gravimetric arrestance) is determined, furthermore, the dependence of the change in the pressure loss of the filter on the weight of the collected dust and the value of the test dust capacity is determined.

This chapter summarises the conversion relationships (tables) between the two classification systems provided by some reputable manufacturers and suppliers of general ventilation filters, or the conversion relationships reported by some major foreign standards or interest group publications, such as the EUROVENT Air Conditioning Manufacturers Association, the and European Ventilation Industry Association (EVIA).

The first information on the separation abilities of the EN 779 filter classes for PMₓ particulate matter fractions was provided by Camfil in its publication [12] from 2017, which we have already cited in the article [10]. The disadvantage of this work from today’s point of view, according to ISO 16890, is the fact that the stated limit efficiencies apply to the whole range of particle sizes of the PMₓ fraction, i.e., to particles smaller than 0.3 µm, and the stated limit values do not exactly correspond to the values of ePMₓ efficiencies. The second disadvantage of the cited publication from today’s point of view, according to ISO 16890, is that it does not state which atmospheric dust that the efficiencies of the individual filter classes according to EN 779 were determined for.

The limit efficiency values of the PMₓ fractions for the individual filter classes of groups M and F are given in Table 4.

Filter class EN 779 | Efficiency for the particulate matter fractions PM1, PM2.5 a PM10 | ||

PM1 | PM2.5 | PM10*) | |

M5 | < 20% | < 40% | > 50% |

M6 | < 40% | 50 – 60% | > 60% |

F7 | 50 – 75% | > 70% | > 80% |

F8 | 70 – 85% | > 80% | > 90% |

F9 | > 85% | > 90% | > 95% |

*)Authors’ note: ISO 16890 works with the ePMₓ efficiency determined for the atmospheric dust particles in the particle size range of 0.3 to x µm. The mass fraction of particles smaller than 0.3 µm (undersize) is not negligible for atmospheric dust and, according to the data in Figure 1, it makes up 18% (urban dust) and 9% (rural dust) of the total mass of the particles for the used atmospheric dusts. As can be seen from the graphs of the initial fractional efficiencies Ef (a) shown in our publication [10]in Figures 1 and 2, the dependence Ef (a) on lower classes of general ventilation filters generally has a decreasing tendency with a decreasing particle size. An exception is the F class of filters, where the diffusion effect already begins to be applied to fine particles smaller than 0.3 µm and the resulting fractional efficiency starts to increase slightly. If we want to determine the filter efficiency for the whole PMₓ particle fraction, then the contribution of the separated particles in the size range 0 to 0.3 µm will vary significantly depending on the filter class and the particle size range used and will increase with an increasing filter class. |

For the above reasons, the information in the Table 4 cannot be directly used to convert filters from EN 779 to EN ISO 16890. However, with regard to a possible error in calculating the ePMₓ value, in our opinion, it is possible to use the stated PM10 values as “indicative” values for ePM10, because, for atmospheric dust in general, the proportion of fine particles of size 0 to 0.3 µm is relatively small and the possible error in determining the value of ePM10 is also small.

The EUROVENT Guidebook [11] from March 2017 contains a conversion table according to the revised national standards - German VDI 3804 - 4 and Swiss SWKI VA101-01. This conversion table is given in Table 5 and only applies to the selected filters of the M5, F7 and F9 classes.

Table 5. Conversion table between the selected filters according to EN 779:2012 and ISO 16890-1:2016 [11]

Filter class | Notes | |

EN 779:2012 | EN ISO 16890-1:2016 | |

M5 | ePM10 ≥ 50% |

|

F7 | ePM2.5 ≥ 65% | In the case that this is not the last stage of filtration |

F7 | ePM1 ≥ 50% | In the case that this is the last stage of filtration |

F9 | ePM1 ≥ 80% |

|

A similar conversion table of selected filters of the M5, F7 and F9 classes, as a recommendation of the expert working group VDI – SWKI, is presented in the TROX Technik materials [13]. The only difference, compared to the data in Table 5, is the indicated value of efficiency without the ≥ sign.

A simple indicative conversion table was presented in 2017 in Status Report No. 44 from the professional association Fachverband Gebaude-Klima e.V. [14]. The conversion data are given in Table 6.

Table 6. Conversion table between the filters according to EN 779 and ISO 16890 according to [14]

Filter class according to EN 779 | ISO ePM1 | ISO ePM2.5 | ISO ePM10 | ISO coarse |

G2 |

|

|

| > 30% |

G3 |

|

|

| > 45% |

G4 |

|

|

| > 60% |

M5 |

|

| ≥ 50% |

|

M6 |

| ≥ 50% |

|

|

F7 | ≥ 50% |

|

|

|

F8 | ≥ 70% |

|

|

|

F9 | ≥ 80% |

|

|

|

According to the Systemair [15] documents, the European Ventilation Industry Association EVIA (see Table 7) shows almost the same conversion table, as seen in Table 6.

Table 7. Conversion table between filters according to EN 779 and ISO 16890 according to [15]

Filter class according to EN 779 | ISO ePM1 | ISO ePM2.5 | ISO ePM10 | ISO coarse |

G2 |

|

|

| ≥ 30% |

G3 |

|

|

| ≥ 45% |

G4 |

|

|

| ≥ 60% |

M5 |

|

| ≥ 50% |

|

M6 |

| ≥ 50% |

|

|

F7 | ≥ 50% |

|

|

|

F8 | ≥ 70% |

|

|

|

F9 | ≥ 80% |

|

|

|

As in the previous two cases, the transfer between the two systems is given in the form of the minimum efficiencies, i.e., open separation ranges of ePMₓ. The only difference compared to the data in Table 6 is the use of the sign ≥ for the class G filter separation ranges also.

The Systemair [15] presentation provides an indicative conversion table between the filter classes according to EN 779 and the “closed” ePMₓ and the ISO coarse efficiencies ranges according to ISO 16890.

Table 8 is unconventionally arranged according to the particulate matter fractions and the achieved ePMₓ efficiencies. From Table 8, it also shows the alternative use of the filters for different particle size distributions, e.g., the possibility of using the equivalents of filter class F7 for the separation of fine PM1 fractions and, at the same time, for the separation of the PM2.5 fractions.

PM1 |

| PM2.5 |

|

ISO ePM1 95% | F9 | ISO ePM2.5 95% | F7 |

ISO ePM1 90% | ISO ePM2.5 90% | ||

ISO ePM1 85% | ISO ePM2.5 85% | ||

ISO ePM1 80% | ISO ePM2.5 80% | ||

ISO ePM1 75% | F8 | ISO ePM2.5 75% | |

ISO ePM1 70% | ISO ePM2.5 70% | ||

ISO ePM1 65% | F7 | ISO ePM2.5 65% | |

ISO ePM1 60% | ISO ePM2.5 60% | M6 | |

ISO ePM1 55% | ISO ePM2.5 55% | ||

ISO ePM1 50% | ISO ePM2.5 50% |

PM10 | Coarse | ||

ISO ePM10 95% | M6 | ISO coarse 95% | G4 |

ISO ePM10 90% | ISO coarse 90% | ||

ISO ePM10 85% | ISO coarse 85% | ||

ISO ePM10 80% | ISO coarse 80% | ||

ISO ePM10 75% | ISO coarse 75% | ||

ISO ePM10 70% | ISO coarse 70% | ||

ISO ePM10 65% | ISO coarse 65% | ||

ISO ePM10 60% | M5 | ISO coarse 60% | |

ISO ePM10 55% | ISO coarse 55% | G3 | |

ISO ePM10 50% | ISO coarse 50% | ||

| ISO coarse 45% | ||

ISO coarse 40% | G2 | ||

ISO coarse 35% | |||

ISO coarse 30% | |||

In addition to this valuable form of filter conversion, the presentation [15] also presents a simple conversion table of the selected filter classes in the form of characteristic efficiencies, see Table 9.

Table 9. Conversion table between the filters according to EN 779 and ISO 16890 according to [15]

Filter class according to EN 779 | ISO ePM1 | ISO ePM10 | ISO coarse |

G2 |

|

| 30% |

G3 |

|

| 50% |

G4 |

|

| 60% |

M5 |

| 55% |

|

F7 | 60% |

|

|

From the comparison of these data with the values in Table 6 and 7, it is clear that the stated efficiencies in Table 9 do not express the minimum values of the efficiencies achieved for the class of filters according to EN 779, but they express the “characteristic” or “mean” values of the efficiencies.

The same indicative conversion table between the filters according to EN 779 and ISO 16890, as seen in Table 8, is stated by Robatherm [16] in its material.

Following the arrangement of the table, according to the application for the separation of particulate matter fractions PM1, PM2.5, PM10 and the L2 synthetic dust, the equivalents of the fine filters intended for the separation of the PM1 fractions are required to have a minimum efficiency of 50% for filters in an untreated and electrostatically discharged state.

The same is required for medium filters, where the minimum efficiency for the separation of the particulate matter fraction PM2.5 for the filters in the untreated and electrostatically discharged state is 50% (ePM2.5).

For the medium filters designed to separate the particulate matter fraction PM10, a minimum efficiency of 50% (ePM10) is required for the untreated filters. There are no electrostatic discharge requirements.

There are no electrostatic discharge requirements for the coarse filters.

A similar approach, when comparing the applicability of the filters according to EN 779: 2012 and EN ISO 16890-1: 2016, is used in the EUROVENT Directive 4/23 - 2018 [17], where Annex 1 compares class M and F filters with the filter classification according to ePMₓ in the form of the corresponding ePMₓ efficiencies ranges. The stated values are the result of the comparative tests performed on the manufacturers, members of the EUROVENT association, who have a 70% share of the European market. The results of the comparison are shown in Table 10.

Table 10. Conversion table between the filters according to EN 779:2012 and EN ISO 16890-1:2016 [17]

Filter class EN 779 | Efficiency for the particulate matter fractions PM1, PM2.5 a PM10 | ||

PM1 | PM2.5 | PM10 | |

M5 | 5 – 35% | 10 – 45% | 40 – 70% |

M6 | 10 – 40% | 20 – 50% | 60 – 80% |

F7 | 40 – 65% | 65 – 75% | 80 – 90% |

F8 | 65 – 90% | 75 – 95% | 90 – 100%*) |

F9 | 80 – 90% | 85 – 95% | 90 – 100%*) |

*)Authors’ note: With respect to the stated upper limit of 100%, all the values given in the table probably indicate the calculated values of the ePMₓ efficiencies before rounding downwards to 5%. |

For mutual comparisons, Table 11 to 15 summarise the conversion relationships between EN 779: 2012 and EN ISO 16890-1: 2016 for the individual filter classes according to EN 779: 2012.

Table 11. Summary of the conversion relationships for the coarse filters of group G.

Source | G2 | G3 | G4 |

ISO coarse [%] | ISO coarse [%] | ISO coarse [%] | |

FGK [14] | > 30 | > 45 | > 60 |

Systemair [15] | 30 – 40 | 45 – 55 | 60 – 95 |

Systemair [15] | 30 | 50 | 60 |

EVIA in [15] | ≥ 30 | ≥ 45 | ≥ 60 |

Robatherm [16] | 30 – 40 | 45 – 55 | 60 – 95 |

Table 12. Summary of the conversion relationships for the medium filters of group M.

Source | M5 | M6 | ||||

ePM1 [%] | ePM2.5 [%] | ePM10 [%] | ePM1 [%] | ePM2.5 [%] | ePM10 [%] | |

Camfil [12] | - | - | > 50 | - | - | > 60 |

VDI – SWKI in [11] | - | - | ≥ 50 | - | - | - |

VDI – SWKI in [13] | - | - | 50 | - | - | - |

FGK [14] | - | - | ≥ 50 | - | ≥ 50 | - |

EVIA in [15] | - | - | ≥ 50 | - | - | - |

Systemair [15] | - | - | 50 – 60 | - | 50 – 60 | 65 – 95 |

Systemair [15] | - | - | 55 | - | - | - |

Robatherm [16] | - | - | 50 – 60 | - | 50 – 60 | 65 – 95 |

Eurovent [17] | 5 – 35 | 10 – 45 | 40 – 70 | 10 – 40 | 20 – 50 | 60 – 80 |

Table 13. Summary of the conversion relationships for the fine filters of class F7.

Source | F7 | ||

ePM1 [%] | ePM2.5 [%] | ePM10 [%] | |

Camfil [12] | - | - | > 80 |

VDI – SWKI in [11] | ≥ 50 last stage | ≥ 65 | - |

VDI – SWKI in [13] | 50 > 50 last stage | - | -

|

FGK [14] | ≥ 50 | - | - |

EVIA in [15] | ≥ 50 | - | - |

Systemair [15] | 50 – 65 | 65 – 95 | - |

Systemair [15] | 60 | - | - |

Robatherm [16] | 50 – 65 | 65 – 95 | - |

Eurovent [17] | 40 – 65 | 65 – 75 | 80 – 90 |

Table 14. Summary of the conversion relationships for the fine filters of class F8.

Source | F8 | ||

ePM1 [%] | ePM2.5 [%] | ePM10 [%] | |

Camfil [12] | - | - | > 90 |

FGK [14] | ≥ 70 | - | - |

EVIA in [15] | ≥ 70 | - | - |

Systemair [15] | 70 -75 | - | - |

Robatherm [16] | 70 – 75 | - | - |

Eurovent [17] | 65 – 90 | 75 – 95 | 90 – 100 |

Table 15. Summary of the conversion relationships for the fine filters of class F9.

Source | F9 | ||

ePM1 [%] | ePM2.5 [%] | ePM10 [%] | |

Camfil [12] | - | - | > 95 |

VDI – SWKI in [11] | ≥ 80 | - | - |

VDI – SWKI in [13] | 80 | - | - |

FGK [14] | ≥ 80 | - | - |

EVIA in [15] | ≥ 80 | - | - |

Systemair [15] | 80 – 95 | - | - |

Robatherm [16] | 80 – 95 | - | - |

Eurovent [17] | 80 – 90 | 85 – 95 | 90 – 100 |

The comparison tables of the individual filter classes show a very good agreement in the achieved efficiencies for the L2 synthetic dust according to ISO 15957, according to the individual sources for the G2 to G4 coarse filters. The particle size distribution of the synthetic dust is shown in [9] in Figure 1 and the mass median is about 10 µm.

Also, for the medium M5 and M6 filters, the data from the individual sources are in good agreement, with the only exception being for the M6 filters and the ePM2.5 efficiency. According to the Eurovent data [17], the efficiency of these filters is 20 to 50%, while according to other sources, the efficiency is ≥ 50%, respectively 50 to 60%.

For fine F7 to F9 filters, the data from the individual sources are in good agreement, again with the exception of the data according to Eurovent [17], where, for the F8 filters and the ePM1 efficiency, the given wide range of efficiencies 65 to 90% does not correspond to narrower range 70 to 75% according to the data from [15] and [16].

A comparison of the reported “open” efficiency ranges (≥ XY%) and the “closed” efficiency ranges (from - to) for all the filters, also results in a realistic estimate of the actual efficiency range for the reported “open” efficiencies.

A fundamental change in the classification and use of filters for general ventilation was brought about by the ISO standard 16890, which introduces new indicators for the testing and classification of filters – the PM10, PM2.5 and PM1 particulate matter fractions and uses the values of the total ePMₓ filter efficiency, based on the experimentally determined dependence of the fractional efficiency on the particle size in the range 0.3 µm to x µm.

The paper summarises the main differences between the original classification of the filter according to EN 779 and the new classification according to EN ISO 16890 and explains the problem of the direct reclassification of the filter classes of EN 779 to the filter classes according to EN ISO 16890.

The main content of the paper is a list of the known conversion relationships between the original and the new classification of filters, which are listed by some renowned manufacturers of filters for general ventilation, some national standards or publications of interest groups, such as the association of air conditioning manufacturers EUROVENT and the European Ventilation Industry Association (EVIA).

Although the stated transfer relationships between the two classification systems are only indicative and, due to the diversity of the systems, they cannot be otherwise different, we believe that they can contribute to the successful transition to the new classification system and its implementation.

Article reviewed by doc. Ing. Vladimír Zmrhal, Ph.D.

[1] ISO 16890-1 Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM), ISO 2016.

[2] EN 779 Particulate air filters for general ventilation – Determination of the filtration performance, 2012

[3] EN ISO 16890-1 Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM), 2016.

[4] EN ISO 16890-2 Air filters for general ventilation – Part 2: Measurement of fractional efficiency and air flow resistance, 2016.

[5] EN ISO 16890-3 Air filters for general ventilation – Part 3: Determination of the gravimetric efficiency and the air flow resistance versus the mass of the test dust captured, 2016.

[6] EN ISO 16890-4 Air filters for general ventilation – Part 4: Conditioning method to determine the minimum fractional test efficiency, 2016.

[7] EN 13779 Ventilation for non-residential buildings – Performance requirements for ventilation and room-conditioning systems, 2007.(replaced by EN 16789-3)

[8] EN 16789-3 Energy performance of buildings – Ventilation of buildings – Part 3: For non-residential buildings – Performance requirements for ventilation and room-conditioning systems, 2017.

[9] MOJŽÍŠ, M. Komentář a doplnění článku „Normalizace a odlučovací schopnosti filtrů pro všeobecné větrání“ (VVI č. 1/2018) a současné problémy s měřením a tříděním filtrů, VVI 4/2018, s. 246–250.

[10] HEMERKA, J., VYBÍRAL, P. Normalizace a odlučovací schopnosti filtrů pro všeobecné větrání, VVI 1/2018, s. 29–35.

[11] EUROVENT Guidebook „Air filters for general ventilation, March 2017.

[12] PM1 – Fine Dust Hazard to Health, Clean Air Solutions, Camfil, 2017.

[13] ISO 16890 – The new standard for coarse dust and fine dust filters, TROX Technik, 2017.

[14] Status Report Nr. 44, Fachverband Gebaude-Klima e.V., 2017.

[15] ISO 16890 – Air filters for general ventilation, Systemair, MBM 2018 – 15. and 16. May 2018.

[16] 49 tříd filtrace místo 9 – Norma ISO 16890 pro vzduchové filtry přehledně, Robatherm, 2018.

[17] EUROVENT Guideline 4/23 – 2018 Selection of EN ISO 16890 rated filter classes for general ventilation applications, Second edition, October 2018.

Follow us on social media accounts to stay up to date with REHVA actualities

0