Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

Christian Bremer |

Managing Director Condair GmbH, Germanychristian.bremer@condair.com |

Modern buildings, with their tight building envelopes, are designed to save energy and thus prevent the natural air exchange by infiltration. Mechanical air ventilation systems are designed to create completely different indoor air conditions versus the outside and generate comfortable temperatures in the range of 20-26°C. Yet especially in winter, this indoors warm air is also very dry, at 10-30% relative humidity (RH) – such climate exists in nature only in the desert, while in temperate climate zones, one can find this in buildings only!

This excessively dry indoor air is often perceived as uncomfortable: effects such as itchy skin, irritated eyes, scratchy feeling in the throat are the telling signs, besides the reduced performance and fatigue, both also directly caused by insufficient humidity. However, the less known phenomenon is the drying out of the mucous membranes in the respiratory tract, which weakens our defense mechanism against airborne infection. If the air we are breathing in is below 40%RH over a prolonged period, this mucous membrane layer dries out, causing damage to the cilia - tiny hair-shaped structures acting as pollutants and germs filter from the air we breathe in. This can lead to respiratory diseases – from the common colds, bronchitis, sinusitis to influenza, as several epidemiological studies reveal. [1]

Medical evidence [2] shows that the optimal indoor air parameters for comfort and health protection lie in the range of 21-22°C and a relative humidity between 40-60%.

Adequate humidification during the heating period is not only beneficial to health but also essential for valuables preservation – whether in homes or in museums and churches: objects made out of wood and paintings crack as they release their material moisture into the dry environment. Same for paper, leather and other hygroscopic materials. In several processing industries, manufacturing or storage of certain commodities, as well as for electronic data processing equipment the humidification control is mandatory, whether to increase productivity, preserve goods or to prevent electrical discharges: one spark can cause material damage and the production stops.

Yet for most consultants, humidification projects do not occur frequently, so it’s difficult to build-up the expertise needed to avoid the many potential design errors that can occur. Additionally, when considering humidification in air conditioning, besides many factors impacting the correct humidifier specification – some obvious, such as the available energy source, and some not so, such as water quality or the cost of maintenance – there seems to be a main reluctance deriving from hygiene concerns and anticipated potential project issues with clients and contractors. They don’t need be!

So, let’s look first at the main systems and then at the layout and considerations for a hygienic and efficient operation.

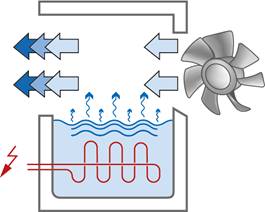

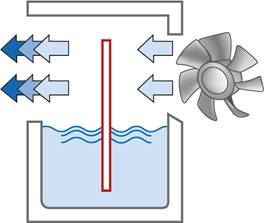

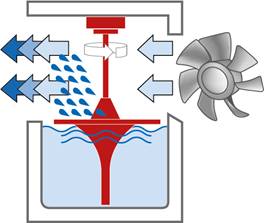

Humidification is provided based on the three physical methods of vaporization, atomization or evaporation. From the hygienic standpoint, the three methods have different requirements for the humidification equipment.

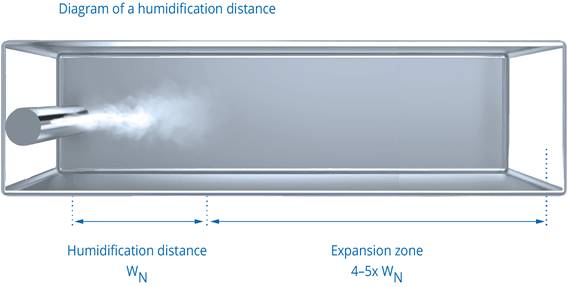

Steam humidification provides least concerns in terms of hygiene because of the high temperature level. The steam distributors are to be correctly placed and humidification distance correctly determined. The humidification distance is the distance required for optimum absorption of steam by the air. Essentially, it comprises the mist zone and the expansion and mixing zone. If existing humidification distances are very short, i.e. from 0.5 to 1 m, multiple steam distribution systems are the preferred choice.

The humidification distance in evaporation humidifiers is pre-determined by humidifier design. Preventive measures to avoid biofilm growth on the evaporation media are to be taken.

Atomization humidifiers represent the greatest challenge from the hygiene point of view. Water aerosols must not enter the air ducts downstream of the humidification system as they can form hygienically hazardous damp surfaces in there.

The overall humidification distance, consists of two zones: the mist zone and the subsequent expansion and mixing zone. The mist zone is the section downstream of the humidification system –from the water droplets respectively steam injection to the complete absorption of the steam by the air. In the following expansion and mixing zone humidity mixes evenly with the air stream. To prevent condensation inside the air duct the humidity sensor needs to be placed after the expansion and mixing zone.

The humidification distance in adiabatic humidification systems such as hybrid humidifiers or surface evaporators is provided by design. A hybrid humidifier uses two adiabatic humidification methods. An atomizer unit and an evaporator unit are used in parallel to achieve the most efficient humidification result and an outstanding level of hygiene quality.

It is significantly more difficult to specify the humidification distance in high-pressure and ultrasonic atomizers. The key parameters are: humidity increase, air temperature, air speed, flow profile and the aerosols size.

A small number of microorganisms may settle in

· Humidifier water supply lines

· Water lines inside humidification systems

· Evaporation bodies

· Droplet separators (to remove unevaporated water droplets from the air stream, ensuring droplet-free humidification - for optimal hygiene.)

· Water basins

· Humidifier chambers

and can form a biofilm there. Over the course of a few days to months, the biofilm will grow to a certain thickness and reaches its stationary phase. From this time onwards, the biofilm continuously releases germs, and the uncontrolled contamination of the humidifying water and system air follows.

Biofilms may settle on all humid surfaces and often remain unnoticed in humidification systems for a long period. The supply water for humidifiers should have the same microbiological quality as potable water i.e. maximum value of 100 CFU/mL.

The formation of biofilms can be prevented only by a combination of relevant measures:

· Hygienic humidification water

· No water stagnation in the water lines

· Efficient measures for microbial reduction

· Periodic and strict cleaning and disinfection

Did you know how quickly microorganisms can spread? · After 2 hours: 8 germs · After 6 hours: 512 germs · After 12 hours: 262,144 germs · After 18 hours: 53,667,776 germs · After 24 hours: 68,719,476,736 germs |

From a hygiene standpoint, the proper control of humidification systems is of great importance. Falling below the dew point must be avoided so no condensation gets deposited in the air duct system.

Steam humidification is in principle an isothermal process: Only a small increase in air temperature occurs due to the humidification process. For this reason, only the system and room humidity values need to be controlled.

Yet, when atomizing or evaporating water, the humidified air cools down considerably. Therefore, in these cases, temperature control is also crucial for humidity control.

Reliable hygiene proofs include all hygiene-related aspects: microbiological long-term stability, preventive hygiene measures and periodic and strict maintenance and service. Only meeting the technical and structural compliance of devices and components according to specific guidelines do not constitute evidence of hygienic operation.

The humidification system hygiene is provided only if all aspects are covered:

· Correct sizing of humidification distances

· Prevention of biofilm formation

· Prevention water aerosols spread

· Provide system-compatible humidity control

· Provision of hygiene proofs

EN 16798 Part 3 “Energy performance of buildings – Ventilation of buildings – Ventilation of non-residential buildings – Performance requirements for ventilation and air-conditioning systems and room cooling systems”.

Drinking Water Ordinance (TrinkwV, Appendix 1 “Microbiological parameters”, Part II “Requirements for drinking water intended for delivery in sealed containers”).

VDI 6022 sheet 1 — “Ventilation technology, indoor air quality – Hygiene requirements for ventilation and air-conditioning systems and devices”.

[1] e.g. Noti et al 2013, Lester W. 1948, Casanova et al 2010, Lowen et al 2007, Yang W., Marr L. 2011, Yang W., Marr L. 2012, Myatt T.A. et al 2010, etc.

[2] Criteria for human exposure to humidity in occupied buildings

Author: Sterling EM et al, 1985;

Study: High humidity leads to loss of infectious influenza virus from simulated

coughs Author: Noti JD et al, 2013; Study: Dynamics of airborne influenza A

viruses indoors and dependence on humidity Author: Yang W, Marr LC.

Follow us on social media accounts to stay up to date with REHVA actualities

0