Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

| ||

| ||

| ||

|

|

|

Daniel Carbonell Sanchez | Mihaela Dudita | Spyridon Pantelis |

SPF Institute for Solar Technology, Rapperswil, Switzerlanddani.carbonell@ost.ch | SPF Institute for Solar Technology, Rapperswil, Switzerland | REHVA, Brussels, Belgium |

|

|

|

Alireza Zendehboudi | Xabier Anton Peña | Maike Schubert |

Norwegian University of Science and Technology, Trondheim, Norway | Tecnalia, Gipuzkoa, Spain | SPF Institute for Solar Technology, Rapperswil, Switzerland |

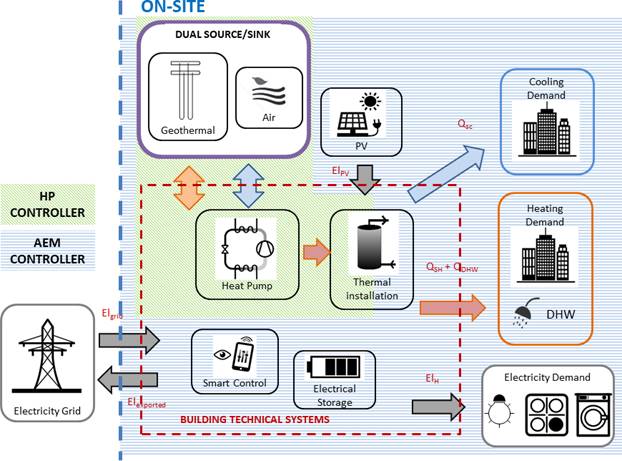

Funded by the European Union’s Horizon 2020 Research and Innovation Programme, and coordinated by SPF Institute of Solar Technology, TRI-HP project (https://www.tri-hp.eu/project) is a four-year Horizon 2020 project that started in March 2019. Within the project, two main systems will be developed:

· Dual-source/sink heat pump system with the possibility to use ground and/or air as heat sources/sinks.

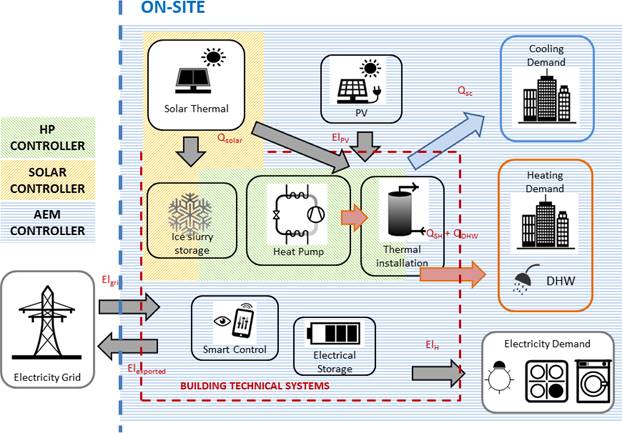

· Solar-ice system based on supercooling ice-slurry heat pump with solar energy as the main renewable heat-source.

TRI-HP systems will include advanced controls, managing electricity, heat and cool in a way that optimises the performance of the system and increases its reliability via failure self-detection. Moreover, TRI-HP will provide the most appropriate knowledge and technical solutions to cope with stakeholder’s needs, building demand characteristics, local regulations and social barriers, with an on-site renewable share of 80%, reducing the installation cost by 10-15%.

Figure 1. Dual-source/sink heat pump system with the possibility to use ground and/or air as heat sources/sinks.

Buildings can be efficiently supplied with renewable heating and cooling using what is known as solar-ice systems. These systems combine solar thermal collectors, heat pumps and ice storage to supply the energy needs in heating dominated regions with enough solar irradiation, e.g. Central Europe.

Solar-ice systems use solar thermal collectors as the only heat source for the heat pump. Solar thermal collectors are also used to supply heating and domestic hot water demands directly. As long as the sun is shining or the ambient temperature is not too low, solar collectors act as a direct heat source for the heat pump. During cold nights or days with low solar irradiation, when the energy from the solar collectors is insufficient to generate enough heat for running the heat pump directly from the solar collectors, the ice storage is used as a temporary heat source. Turning liquid water into ice releases a lot of thermal energy: icing 1 kg of water provides approximately the same energy as cooling down the same amount of water from 80°C to 0°C. Thus, the ice storage can store solar heat with a high volumetric storage capacity.

Figure 2. Solar-ice system based on supercooling ice-slurry heat pump with solar energy as the main renewable heat source.

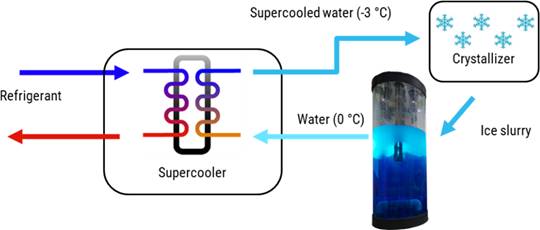

The solar ice-slurry system is a particular case of the solar-ice system. The main difference between them is that in the ice slurry concept, the ice storage contains no heat exchangers, which reduces the system installation cost by 10%. Moreover, the heat exchanger (supercooler) is always free of ice and thus has a higher efficiency compared to ice-on-coil.

The solar ice–slurry system can be compared to ground source heat pumps (GSHP) with the benefits of not having to drill boreholes and thus not being restricted by water protection laws. Moreover, there is no need to regenerate the ground as in the case of boreholes, even if the storage is buried in the ground since it regenerates on a yearly base by solar energy. This system concept is developed in the TRI-HP project for heating-dominated climates with cooling as an add-on feature using the ice-slurry produced in the storage vessel.

The main technological barrier for solar ice-slurry systems is related to supercoolers, i.e., heat exchangers that can decrease water temperature below 0°C, allowing the existence of water in a meta-liquid state and suppressing the ice formation.

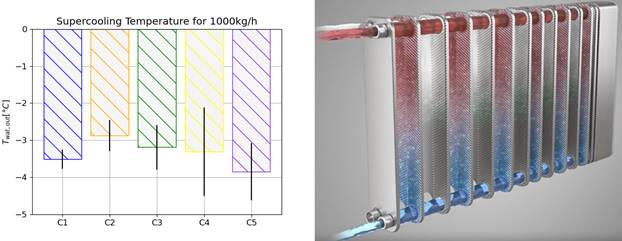

In the context of the TRI-HP project, efficient supercoolers were designed and tested by SPF Institute for Solar Technology (SPF) [1] from OST Eastern Switzerland University of Applied Sciences [2]. For the new supercoolers, icephobic coatings made by the Danish Technological Institute (DTI) [3] from Denmark and Industrielack AG (ILAG) [4] were used and applied to heat exchangers from ALFA LAVAL [5]. The cost of these coatings under the assumption of 250 m² of plates surfaces coated per day is in the range of €4 per kW nominal heat pump capacity.

Figure 3. Schematic representation of the supercooling method used in TRI-HP for the ice-slurry production.

The tested TRI-HP supercoolers reached supercooling degrees up to 4 K, which is well beyond the 2 K achieved by state-of-the-art technologies. The average supercooling temperature was evaluated for seven freezing cycles for different icephobic coatings. Supercooling powers of around 6 kW were achieved with the new heat exchangers. The new supercoolers will be further tested by SPF together with heat pumps during summer 2021. The aim is to assess the full capacity range and reliability under dynamic conditions.

The use of natural and environmentally friendly refrigerants with low Global Warming Potential (GWP) such as hydrocarbons, water, ammonia and carbon dioxide (CO₂) has recently attracted much attention as a measure to mitigate the greenhouse gas emissions from refrigeration, air-conditioning and heat pumping systems. In this vein, new heat pumps with natural refrigerants (propane and carbon dioxide) are being developed and tested in the context of the TRI-HP project.

Figure 4. Experimental supercooling degrees (left) achieved in the SPF test bench using icephobic coatings applied on flat plate heat exchangers (right).

The Norwegian University of Science and Technology (NTNU) [6] from Trondheim (Norway) has developed a single tri-partite gas cooler unit for a new CO₂ heat pump design. This innovative heat pump design includes three brazed plate heat exchangers developed by ALFA LAVAL and aims to simplify the heat pump layout and reduce the piping requirements.

Experimental investigation shows promising performance while having a more compact design and a cost of around €308 per kW nominal heat pump capacity. Under the design conditions, the heat duty meets the requirements to provide the supply temperatures of 35°C and 70°C for space heating and domestic hot water applications.

TECNALIA [7] from Azpeitia (Spain) has developed a dual source heat exchanger for a new propane heat pump design. This innovative heat pump is able to exchange heat with geothermal brine/water or directly with air or against both simultaneously in a smart way without complicate control strategies and the requirement of secondary water loops. Under the design conditions, the heat duty meets the requirements to provide the supply temperatures of 35°C or 70°C for space heating or domestic hot water applications, and 7ºC for space cooling applications. More information can be found on the TRI-HP website.

In the testing facilities of SPF Institute for Solar Technology (SPF) the performance of the following heat pump prototypes was tested under different working conditions and operation modes (see Figure 1and Figure 2):

· (R744) CO₂-ice heat pump

· (R290) propane-ice heat pump

· (R290) propane-dual source heat pump

The experiments analysed in detail the effects of different operating parameters on the overall coefficient of performance, heat duty, and compressor energy consumption.

The CO₂-ice heat pump includes a rotary compressor coupled to an inverter, the tri-partite brazed plate gas cooler, an evaporator, an internal heat exchanger, an ejector, a throttling valve, and a liquid separator. The heat pump unit is designed with a capacity of 10 kW, 8 kW, and 10 kW under only domestic hot water, only space heating, and simultaneous domestic hot water and space heating modes to provide the tap water heating and space heating water up to 70°C and 35°C, respectively. According to the results, the CO₂-ice heat pump shows good performance for high DHW demand with large temperature differences at the gas cooler if the inlet temperature of the gas cooler is low (10°C to 20°C, such typical temperature level of fresh water). In DHW mode, the COP varies between 3.6 and 4.3 for set temperatures of 55°C to 65°C.

The propane-ice heat pump prototype is designed with a capacity of 10 kW and consists of a scroll compressor with inverter, two plate heat exchangers in the heat sink side (desuperheater and condenser), an evaporator, an internal heat exchanger, and several expansion valves. Similarly, to the CO₂-ice heat pump, the propane-ice heat pump was studied at a steady state for only space heating operation, only domestic hot water operation, and simultaneous domestic hot water and space heating operation. The results indicate that the COP for space heating temperature 30/35°C ranges between 4.4 and 5.4. However, the COP of the unit for domestic hot water with a set temperature of 65°C drops to between 2.5 and 2.8.

Figure 5. The propane-dual source heat pump test bench inside the climatic chamber of Tecnalia’s laboratory.

The propane-dual source heat pump with a capacity of 10 kW is designed and manufactured to use both air and/or water/brine coming from geothermal boreholes as heat source/sink, allowing to test this unit under heating and cooling working modes. The results of the propane-dual source heat pump indicate a slightly lower heat duty than the requirements under the design conditions (70 Hz.), while the COP/EER varies between 3.2 and 3.7, depending on the operating mode.

More information about the experiments, the methods and results can be found on D5.5 on TRI-HP’s website: https://www.tri-hp.eu/documents

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N. 814888. The sole responsibility for the content of this paper lies with the authors. It does not necessarily reflect the opinion of the European Commission (EC). The EC is not responsible for any use that may be made of the information it contains. |

|

Follow us on social media accounts to stay up to date with REHVA actualities

0