Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

Stijn Renneboog |

EuroventBrussels, Belgiumstijn.renneboog@eurovent.eu |

Energy efficiency action traces its origins to the 1970s, when consecutive disruptions in the supply of oil caused worldwide concerns over energy security. Many countries enacted energy conservation laws, including minimum energy performance standards for consumer products. In Europe, these were gradually harmonised to enable the free movement of goods in the Single Market. Directives were enacted with harmonised efficiency requirements for boilers (1992), refrigerators (1996) and lighting (2000), and labelling requirements for household appliances (1992).

After the Kyoto Protocol, concerns over climate change became the main driver behind tightening energy efficiency requirements. Eventually, EU-wide product performance requirements were subsumed in the first Ecodesign Directive (2005), which was primarily cast as a measure to reduce greenhouse gas (GHG) emissions. The Ecodesign Directive was recast in 2009, with a scope extension from ‘energy-using products’ (EuP) to ‘energy-related products’ (ErP) – the first step towards more holistic sustainable products legislation.

Product sustainability concerns are becoming more pressing by the day. Humanity’s ecological footprint is estimated to be around 1.6 planet Earths and growing, with around 60% of it accounted for by carbon emissions which are heating the planet [1].

The European Union’s response to the global climate and ecological crises is the so-called European Green Deal (EGD). The EGD is a set of policy initiatives developed by the von der Leyen Commission with the aim to fit the European economy within planetary boundaries and decouple economic growth from resource use. At the centre of it is the aim of making Europe climate neutral by 2050 with the intermediary target of 55% GHG emissions reduction by 2030.

Under the EGD, the next generation of Ecodesign requirements is expected to explore new frontiers for energy savings to help achieve the more ambitious targets. These new frontiers include new product groups, system approaches, and requirements related to the smartness and connectivity of products. That said, where the Commission really intends to break new ground is in resource efficiency, with important implications for product design and manufacturing.

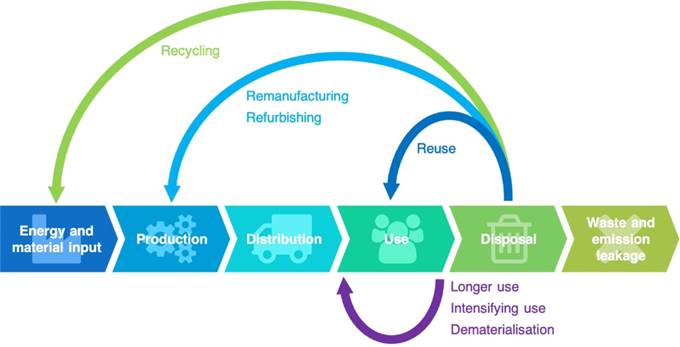

On 11 March 2020, the Commission published the new Circular Economy Action Plan (CEAP) outlining its approach to resource efficiency. The problem the CEAP aims to tackle is easy enough to understand: from 1970 to now, the annual rate of material extraction across the globe has tripled [1]. Around half of total GHG emissions are estimated to come from resource extraction and processing [2]. Only 12% of materials are recovered and fed back into the economy [3]. In brief, humanity is using resources and generating waste faster than our ecosystem can renew, with a big impact on the environment.

In answer to these issues, the Commission aims to reduce waste and close the loop on productive cycles by ensuring that products last longer, and are more easily remanufactured and recycled. Some of the major elements in the new CEAP include strengthening waste legislation, promoting the use of environmental footprint methodologies for products and business, tackling the issue of misleading claims about the sustainability of products, extending producer responsibility via alternative business models like take-back schemes and product-as-a-service, enabling the ‘right to repair’, introducing minimum recycled material rates, and addressing the issue of planned obsolescence.

Figure 1. Circular economy [4].

The Commission suggests targeting the most problematic sectors first: electronics and ICT, batteries and vehicles, packaging, plastics, textiles, construction and buildings, food and water, and intermediary products such as steel, cement and chemicals. HVACR products make up only a small volume of total manufacturing and typically have quite long lifetimes and relatively innocuous material compositions. They are therefore not a priority sector for the Commission’s circular economy measures. Nevertheless, the actions developed under the CEAP will have a major impact on our sector as well.

Indeed, the core policy ambition introduced by the CEAP is the so-called Sustainable Product Initiative. In essence, the Commission is proposing to extend the scope of the Ecodesign Directive to non-energy-related products and regulate under Ecodesign all environmental impacts of products, not just their impact on energy consumption. The preparatory study for this initiative is currently underway.

The extension of the Directive to whole new sectors of the economy is likely to disrupt established workflows and the policy ecosystem in which we are used to work. Frequent delays in the regulatory process and insufficient market surveillance are already preventing the Ecodesign Directive from being as successful as it could be. The industry has therefore expressed concerns over the proposed extension, which risks stretching the Commission’s resources even more thinly, further exacerbating these issues.

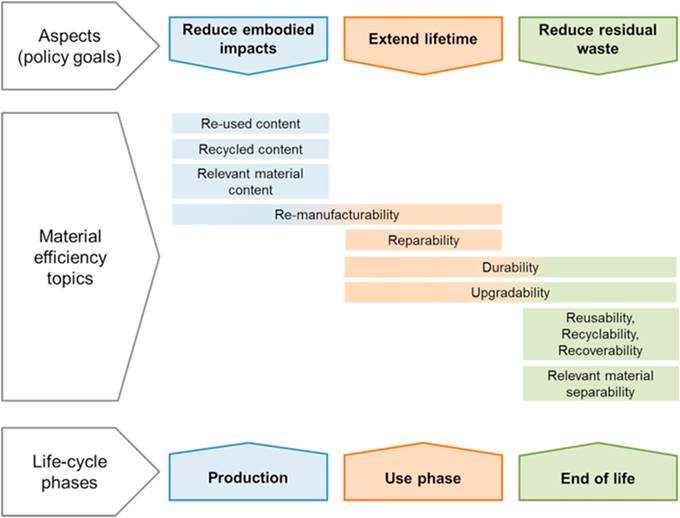

Of greater relevance for product manufacturers is that the Commission is proposing to consistently include requirements related to material efficiency, reusability, reparability, upgradability, durability, recoverability, recycled content, and recyclability in implementing measures under Ecodesign. Although foreseen by the legal text of the Directive itself, the roll-out of such requirements for HVACR products has so far been limited. That is about to change.

Figure 2. Design aspects for circularity[5].

Every four years or so, the Commission develops an Ecodesign Working Plan to take stock of progress made so far, and to plan further work on new measures or the revision of existing ones. Whether and how to include measures under Ecodesign is determined according to the Methodology for the Ecodesign of Energy-related Product (MEErP), which provides a harmonised framework to assess the impact of a measure across several environmental criteria. The Commission prioritises measures where significant improvements are feasible.

The 2016-2019 Ecodesign Working Plan was a game-changer for product circularity requirements. For the first time, the Commission considered the possibility of establishing more circularity requirements such as minimum lifetime of products, availability of spare parts and repair manuals, ease of removal of certain components, marking of plastic parts, and avoiding incompatible plastics, for example.

The Commission also proposed to develop a circular economy toolbox to assess the margin for improvement in material efficiency requirements in a more systematic way across product groups, and to develop a standardisation request regarding material efficiency aspects for Ecodesign. This mandate was taken up by CEN-CLC/TC10, which developed the EN 4555x series of standards published in 2020.

Table 1. The EN 4555x series of standards.

Standard | Topic |

EN 45551:2020 | Standards use guide |

EN 45552:2020 | Durability |

EN 45553:2020 | Ability to re-manufacture |

EN 45554:2020 | Ability to repair, reuse and upgrade |

EN 45555:2020 | Recyclability and recoverability |

EN 45556:2020 | Proportion of re-used components |

EN 45557:2020 | Proportion recycled material content |

EN 45558:2020 | Use of critical raw materials |

EN 45559:2020 | Methods for providing information |

Based on the 2016-2019 Working Plan, circular economy requirements were ultimately included in numerous implementing measures. For example, the regulation covering refrigerators with a direct sales function (published in 2019) requires manufacturers to keep certain spare parts available for at least 8 years, to ensure access to repair and maintenance information for professional repairers, and to make certain components easily removable with the use of commonly available tools. It is expected that similar requirements will be mainstreamed into most implementing measures. They have already been proposed for ventilation units, the regulations for which are currently under review.

Circular economy aspects are sure to be further strengthened in the next Ecodesign Working Plan (2020-2024), which is currently under development with publication expected in the third quarter of this year. The preparatory study concluded in April with the publication of the final task reports. The study assessed the feasibility of six additional circular economy aspects, namely (i) light weighting, (ii) recycled content, (iii) ecological profile, (iv) durability, (v) scarce and critical raw materials, and (vi) firmware and software. The preparatory study’s assessment of these measures is comprehensive, and it remains to be seen when and how each of these measures will be considered and implemented for each product group. The landscape of ErP is complex and a one-size-fits-all approach is unlikely to be fruitful. Moreover, the Ecodesign policy cycle is characterised by frequent delays. However, sooner or later these aspects will become the norm for all products.

The MEErP is currently also being reviewed, with the preparatory study carried out by the Commission’s Joint Research Centre (JRC). It is expected that the review will focus on better addressing circular economy aspects in the MEErP, including better harmonisation with Product Environmental Footprinting and with the provisions of the newly published EN 4555x series, including tools to assess durability, recyclability, reusability, and other such aspects. This should allow the Commission to assess the introduction of new circularity requirements for existing products and extending Ecodesign to new products beyond ErP.

The 2020-2024 Ecodesign Working Plan may well be the last Working Plan as we know it. It is expected that after 2024, the Ecodesign Directive will have been extended to non-ErP and the workflows are certain to change. It is anybody’s guess at this point what the effects of the Sustainable Product Initiative will be on the policy cycle, review priorities, market surveillance, and other considerations. In any case, our industry should start to reckon with the circularity measures that will inevitably come their way and be prepared to innovate under the new conditions imposed by the extension of the Ecodesign Directive.

[1] Global Footprint Network. (2021). Home – Global Footprint Network. https://www.footprintnetwork.org/

[2] European Commission. (11 March 2020). A new Circular Economy Action Plan: For a cleaner and more competitive Europe. https://eur-lex.europa.eu/resource.html?uri=cellar:9903b325-6388-11ea-b735-01aa75ed71a1.0017.02/DOC_1&format=PDF

[3] Eurostat. (2019). Monitoring framework – Circular economy. https://ec.europa.eu/eurostat/web/circular-economy/indicators/monitoring-framework

[4] Adapted from Geissdoerfer et al. (2020). The Circular Economy concept. https://commons.wikimedia.org/wiki/File:The_Circular_Economy_concept.png

[5] From Tecchio et al. (2017). In search of standards to support circularity in product policies: A systematic approach. https://europepmc.org/article/med/29200663

Follow us on social media accounts to stay up to date with REHVA actualities

0