Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

Timo Schreck |

Swegontimo.schreck@swegon.com |

The relative humidity in the indoor air in buildings is often associated with various problems and sick building syndromes. In addition, humidification is associated with high operating and service costs. Indoor air humidity control is often related to removing humidity from the building, not controlling it. In some specific building applications, it is necessary to maintain the humidity at a certain level defined by requirements for the use of the building, such as museums, archives, laboratories or diverse processes.

But what about us — people — and the indoor air humidity? We, engineers and indoor air quality scientists, tend to conclude that humidity has a small impact on human well-being and perceived indoor air quality (IAQ). Research communities rarely focus on indoor air humidity. Humidity is even considered only as an aspect of thermal comfort in IAQ ratings. Humidity indeed has some effects on thermal comfort, but its importance in the overall IAQ is more significant than just as a part of thermal comfort. In fact, indoor air humidity has its own dimension in indoor air quality.

This article proposes to use of a balanced approach to humidity, weighing the concerns of the building construction, the economic aspects and human well-being into consideration.

Diverse research studies about the spreading of aerosols through tests and modelling (bacteria and viruses) show some effects of indoor air humidity. The lower limits in these studies are often around RH 20-25%. But what happens when the indoor air humidity drops below RH 20%, or even under RH 10%? Could our annual winter flu season have something to do with indoor air humidity? What about dry skin and dry eyes? Mortality is also higher in the cold season. If we spend 80-90% of our time indoors, maybe it is not just the low outdoor temperatures, but the problem might be in the dry air that comes with the cold outdoor air.

When the outdoor temperature drops below 0°C, we get around RH 20% when the air is heated to 20-22°C. In the climates of northern, central and continental Europe, as well as at higher altitudes, the outdoor air temperature can remain under 0°C for longer periods. If the outdoor temperature drops under -10°C, we will get indoor relative humidity around RH 10% in well ventilated spaces, if no additional humidity is available. This can be confirmed by monitoring humidity levels in non-residential installations around northern Europe.

On the other end of the scale, we have energy and investment costs, and the fact that most humidity related problems in building envelopes could be avoided, if humidity levels are kept low.

Addressing building envelope issues, humidification costs and impact on humans is an optimization problem. So far, the optimization is mainly done, with a few exceptions, by optimizing energy costs and the risk of possible damage to building envelopes. We — people and building users — play a minor role in this humidity equation.

It is often said that relative humidity in a room can be increased when dropping the room temperature. Unfortunately, this has only a marginal impact when the air is dry. With RH 15%, changing room air temperature from 20°C by ±2°C will impact the RH level by less than ±2%. Even with RH 20%, the impact is less than ±3% RH. Remember that dropping the humidity too much will compromise the thermal comfort of the building occupants.

In theory, plain aluminium rotors (condensation rotors) could also recover humidity by condensation during in the coldest wintertime. However, if the extract air is dry, no condensation and therewith no humidity recovery will take place. In the design phase, it is often assumed that the humidity of the extract air would be RH 30%. With this humidity level, condensation could occur, and some humidity will be recovered, but the humidity level of extract air is usually much lower in wintertime.

Humidity recovery with sorption rotors (high-performance humidity recovery rotor) has a 60-90% humidity recovery efficiency. Humidity recovery efficiency remains quite constant in all conditions. Humidity can be recovered even at small humidity level differences between outdoor air and extract air. Mostly sorption wheels are used in hot and humid environment for cooling recovery, but it would have major advantages also in cold climate.

Humidity recovery can dramatically reduce the operating costs for humidification, and humidification capacity and investments. With efficient humidity recovery, the moisture will be reused 3-10 times before it is lost in the exhaust air. We should look humidity as asset in wintertime and act accordingly.

Humidity recovery is also possible with the crossflow and counterflow plate heat exchangers. In some markets, enthalpy plate heat exchangers are well established in residential applications. In non-residential applications, humidity recovery with membrane foil plate heat exchangers is also available. Humidity recovery efficiency rate remains under 60-65%. However, there is a limited offer (suppliers and sizes) for such products on the European market.

In residential buildings we have some natural humidity sources (cooking, laundry and showers, etc.) that increase the indoor humidity. And these often solve the problem of extreme dryness of the indoor air. Depending on the outside temperature and peak production, like in bath rooms, it is even necessary to ventilate the humidity out from the building.

In non-residential buildings the only sources of humidity are humans, plants, and possible moisture accumulated in the interior and in building materials. These humidity sources help to some extent but are usually not enough to make a real difference.

There is also the possibility of increasing the humidity with plants and vegetation. The required quantity of plants is high to achieve any meaningful increase in humidity levels in the building. However, plant walls are a good improvement in indoor air humidity, and they are being installed more and more frequently in high end buildings.

Further development of plant walls are units where the air is circulated through the roots of plants. One plant wall of 1 m width and 2.3 m height can evaporate up to 400 g/h of water with 72 plants and forced ventilation through the roots. It is worth mentioning that some plants are better suited to humidification purposes than others, as humidity generation and day- versus night-time activity may vary. For a bedroom, a plant active in the night fits the purpose, and for offices, a plant active in the daytime.

The most common way to increase the humidity level in the building would be fixed installed or portable humidifiers with steam or adiabatic technology. These solutions are not discussed in this paper, as other articles cover these technologies.

In comfort humidification, the cost impact of the required humidification levels is often underestimated. Could it be reasonable to avoid the very driest periods in winter, e.g. indoor humidity levels below under RH 20-25%? If we limit our requirements to RH 25-35% indoors in the coldest and driest periods, we would save quite some costs.

One may ask whether it is necessary to keep the humidity level strictly at a certain level? What seasonal or daily variations are acceptable? Does the RH level need to be always kept constant, as it is practised for museums and processes? Could we take more flexible approaches in comfort humidification and try to optimize energy cost and avoid risks for the building envelope?

During winter and spring of 2021, Swegon performed a series of tests in its offices in Malmö, Umeå and Luleå. While Malmö is in the south of Sweden, the latter two cities are located in the northern part of Sweden. The offices have floor areas from 120-500 m². The smaller office buildings are made of light wood construction. The larger office in Malmö has the building envelope made of wooden construction with concrete floor structure and exterior cladded with bricks.

The purpose of the test series was not to carry out a scientific academic study, but rather more practical testing of some hypotheses about the dynamic of humidification and some control strategies.

The method for testing was based on the "minimizing water usage principle”, i.e. use humidification only when needed, minimize water consumption and use the best possible humidity recovery.

The ventilation system was set to a constant airflow of 1-1.2 exchange per hour. Humidity recovery was optimized, and new control loops were installed. Ventilation was running for 12-13 hours per day during weekdays. Different humidification levels were tested, and the water consumption of portable humidifiers was registered manually. Humidification was controlled with the hygrostat that was placed on the wall in an open place in the offices.

Data was recorded every minute by an air handling unit using standard data collection routines and integrated room automation system [1]. In addition, the measurements could be followed up online with a remote connection system. This allowed to check the testing conditions in real time and identify any problems during the measurements.

The occupancy rates in the offices were relatively low due to Covid-19 restrictions during the months of February-April in 2021.

Some additional humidification methods were also tested, such as plants and wet towels in the rooms.

The data was analysed using Excel statistical functions.

The daily water consumption model was developed with regression analyses based on daily water consumption and absolute humidity surplus (xin–xout). Later, the model was used to estimate the annual humidification requirements based on actual local weather data.

Weather conditions in northern Sweden were continuously sub-zero temperatures during the testing period. On cold days, the temperature would drop down to −16-18°C, and even under −24°C.

Indoor temperatures were set by users to 21-22°C. Various indoor air humidity set-points (RH 25%, RH 30%, RH 40%) were tested. As the capacity of humidification was limited, the required levels of indoor humidity were not always reached. Especially during very cold weeks, RH 40% was not reached.

The ability to model the humidification requirement based on the daily average absolutely humidity surplus (xin–xout) gave no statistically significant correlation. The coefficient of determination (R2 values) was less than 0.5.

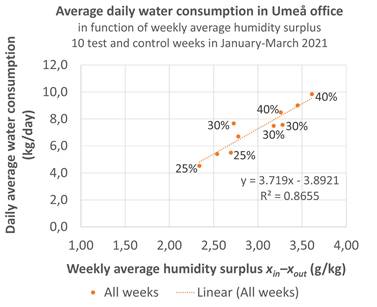

However, when the data for weekly average values was used, the R2 increased to 0.7-0.9 (see Figure 1). This significant improvement can be explained by less data points, the fact that the dynamics of humidity transfer and the accuracy of the measurement arrangement have less impact on the data.

Follow-up test weeks confirmed the accuracy of the model. Prediction for a given control week was in the range of ±10-20%, depending on the RH setpoints, weather and the office locations. This is adequate to estimate the annual humidification requirements with the used control strategy. The results will give an indication of how the humidification requirements would vary dependent on the RH setpoints and locations.

Figure 1. Average daily water consumption as a function of weekly average humidity surplus in Umeå. The % value in data points refers to set point for humidity level.

With the model and with local weather data, annual water consumption could be calculated.

For example, to maintain 30% relative humidity in the Luleå office (120 m²), we would need 1,200 litres of water per year. This corresponds to 850 kWh of evaporation energy in the form of electricity or heating. The electricity cost in Sweden is approximately 1 SEK/kWh = 0.1 €/kWh, which means the additional annual energy costs (for evaporation) are only 850 SEK/a or 85 €/a. In a workplace for 3-5 people, the cost would be 20-30 €/a/person. These costs are much lower than the cost of a single sick day. In Malmö, we could keep about the same cost per m² for 40% relative humidity.

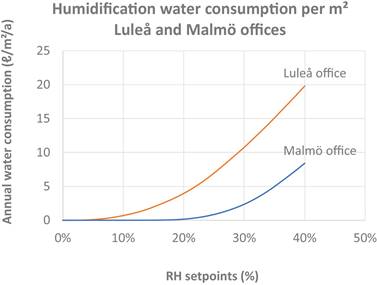

Figure 2 illustrates the impact of location and the RH setpoints on annual water consumption requirements per m². To reach 35% RH indoor air humidity level the impact on the water consumption of location between Luleå and Malmö is 3-fold (5 vs 15 ℓ/m²/a). The increase in water consumption doubles in Luleå when changing the target humidity level from RH 30% to RH 40%. The variations of the RH setpoints have huge impact on water consumption and operation cost, even when we have excellent humidity recovery, as in these sites.

Figure 2. Annual water consumption in Luleå and Malmö.

The surprisingly low humidification requirements at the tested sites with the help of highly efficient humidity recovery and innovative control strategies will raise the question of whether the humidity control should become more widely used in planning, execution, refurbishing and upgrading of ventilation systems.

It is indisputable that the very low indoor air humidity of 10-20% is too dry — both for our health and comfort. It seems that even in the coldest weather conditions, we can increase the humidity level up to 30% with very limited costs. Raising the humidity level to RH 30-40% in Central and Southern Europe should not be beyond reasonable costs.

We would like to emphasize that this was a preliminary field study. These field tests will continue in winter 2021-2022 to ensure that our assumptions are correct and that the control routines work in full scale.

The scientific community in Northern Europe should take a deeper look into the health effects of extreme dry indoor air (RH <20%) in the coming years. Especially in the USA and Canada, there seems to be quite some research on-going in this field.

From economic point of view, it will not make sense to humidify the air without very good humidity recovery and good control systems to minimize costs and risks for the building envelope. In this aspect, we need to improve the indoor air quality with careful actions. On the other end of the scale is however human health, our sensitivity to bacterial and virus diseases in the dry wintertime, and our well-being indoors, both at home and in the workplace. The cost per person of humidity control can be covered by avoiding a single sick day per year. Maybe it is time to raise the discussion of people´s needs to the same level of indoor air humidity requirements as paintings, music instruments, printing machines and laboratory rats.

Follow us on social media accounts to stay up to date with REHVA actualities

0